Ball mill composite liner and manufacturing method thereof

A technology of composite lining board and manufacturing method, which is applied in grain processing and other directions, can solve the problems of lack of general products, inconvenience, etc., and achieve the effects of long service life, improved working environment, and stable work.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

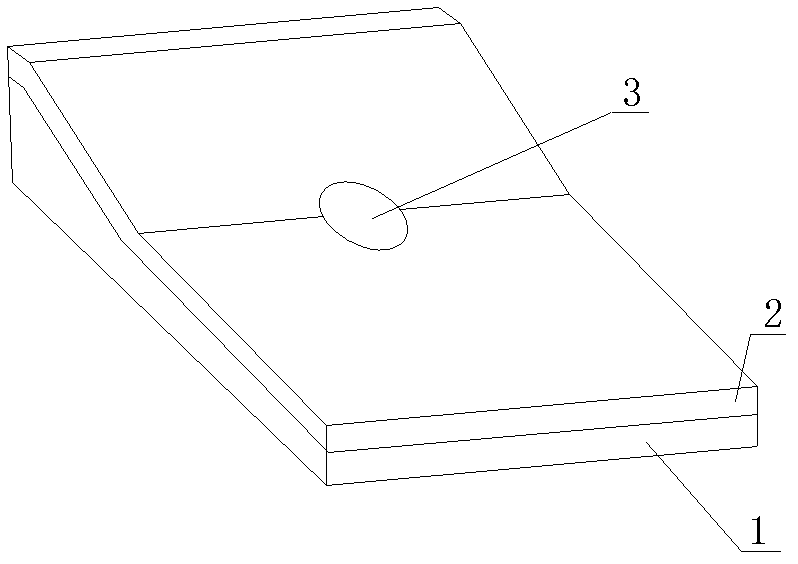

[0043] figure 1 It is a structural schematic diagram of Embodiment 1 of the ball mill composite liner of the present invention. Such as figure 1 As shown, the composite liner of the ball mill includes a plate body with mounting holes 3 on the plate body. The plate body includes a metal bottom layer 1 cast from scrap steel and an ultra-high molecular weight plastic layer 2 pressed on the metal bottom layer. The thickness of the metal bottom layer is about one-third of the total thickness, which can optimize the wear resistance, overall strength and cost of the ball mill composite liner of the present invention. The composite liner of the ball mill in this embodiment is a flat liner, the upper surface of which is composed of a front plane and a rear slope. Wherein the ultra-high molecular weight plastic layer 2 is preferably an ultra-high molecular weight ultra-high structural plastic. The ultra-high molecular weight ultra-high structural plastics are selected from the ultra...

Embodiment 2

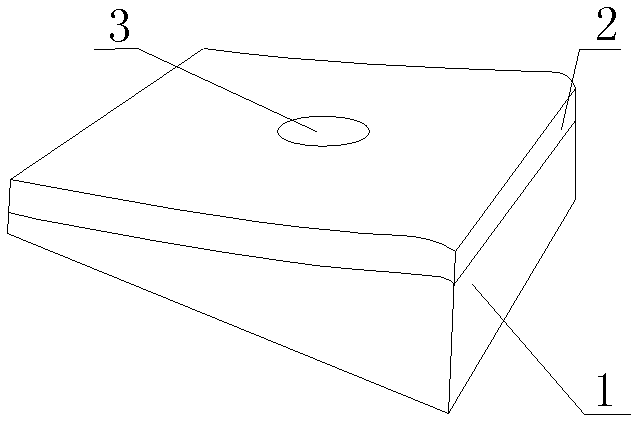

[0045] figure 2 It is a structural schematic diagram of Embodiment 2 of the ball mill composite liner of the present invention. The difference from Example 1 is that the composite liner of the ball mill is a stepped liner, and the side of the liner is trapezoidal. The assembled liner is stepped in the ball mill, which can increase the grinding of materials by steel balls.

Embodiment 3

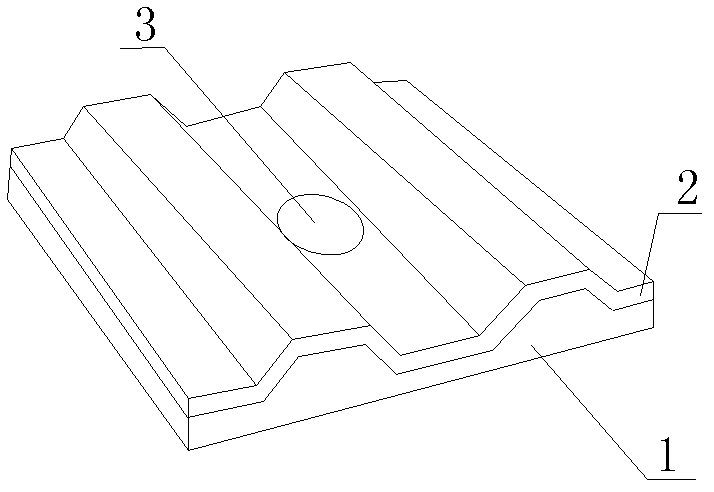

[0047] image 3 It is a structural schematic diagram of Embodiment 3 of the ball mill composite liner of the present invention. The difference from Example 1 is that the composite liner of the ball mill is a corrugated liner, that is, the upper surface of the composite liner of the ball mill has alternate concave and convex stripes in a corrugated shape. It can increase the grinding of materials by steel balls.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com