A precision production method for a light passenger car front brake caliper body

A front brake and production method technology, applied in the field of precision production of light passenger car front brake caliper body, can solve the problems of low production efficiency of brake caliper body, expensive horizontal processing equipment, and inability to match ordinary equipment, etc., to achieve the relevant hole distance position Accuracy, production cost reduction, and the effect of reducing capital investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

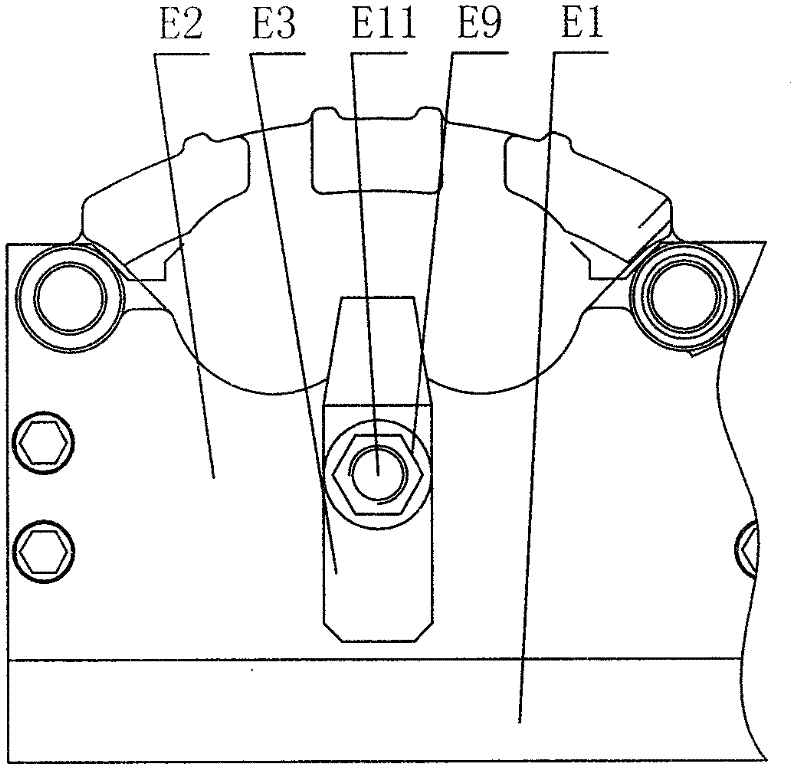

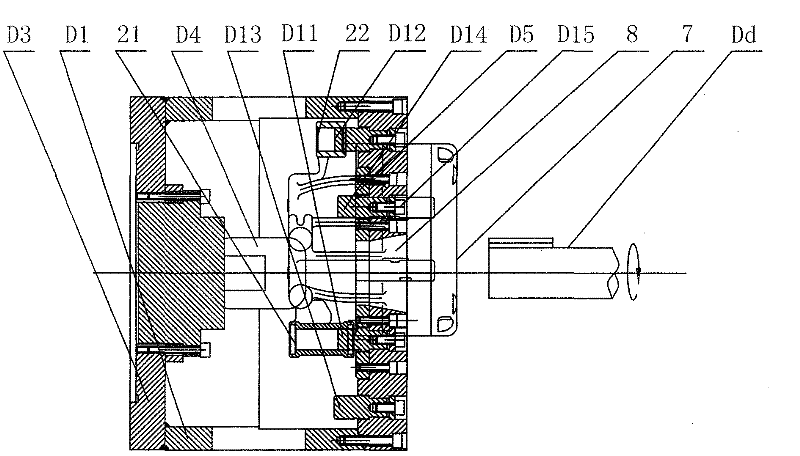

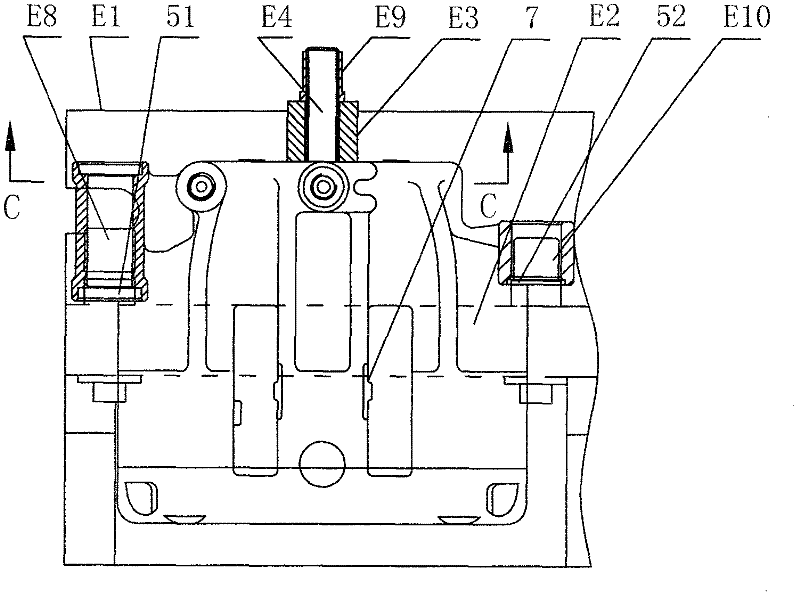

[0028] The technical solution of the present invention will be further specifically described below in conjunction with the accompanying drawings. Brake caliper body 7 (such as figure 1 , 2 , shown in 3) the production steps are: A. milling caliper body oil cylinder working face (81,82) arc: on the CNC milling machine, caliper body 7 is fixed on the fixture, let oil cylinder working face 81,82 be vertical, adopt The three-sided edge milling cutter mills the arc of the working surface of the oil cylinder (such as Image 6 As shown), the cutting speed is 140r / min, the feed rate is 100mm / min, there is no burr on the surface by visual inspection, and the arc of the working surface of the cylinder of the caliper body is milled out.

[0029] see Figure 4 , 5 6. In the circular arc process of milling caliper body oil cylinder working surface 81, 82, the structure of the fixture used is: the base A1 is provided with a core seat A2, the rear side of the core seat A2 is provided wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com