Tool and method for replacing large-end bearing shell of connecting rod in diesel engine of mega-kilowatt nuclear power plant

A connecting rod big end, diesel engine technology, applied in the direction of manufacturing tools, hand-held tools, etc., can solve the problems of increased secondary risks, the amount of disassembled parts, and large manpower and physical costs, so as to reduce maintenance costs and shorten The maintenance period and the effect of saving man-hours

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

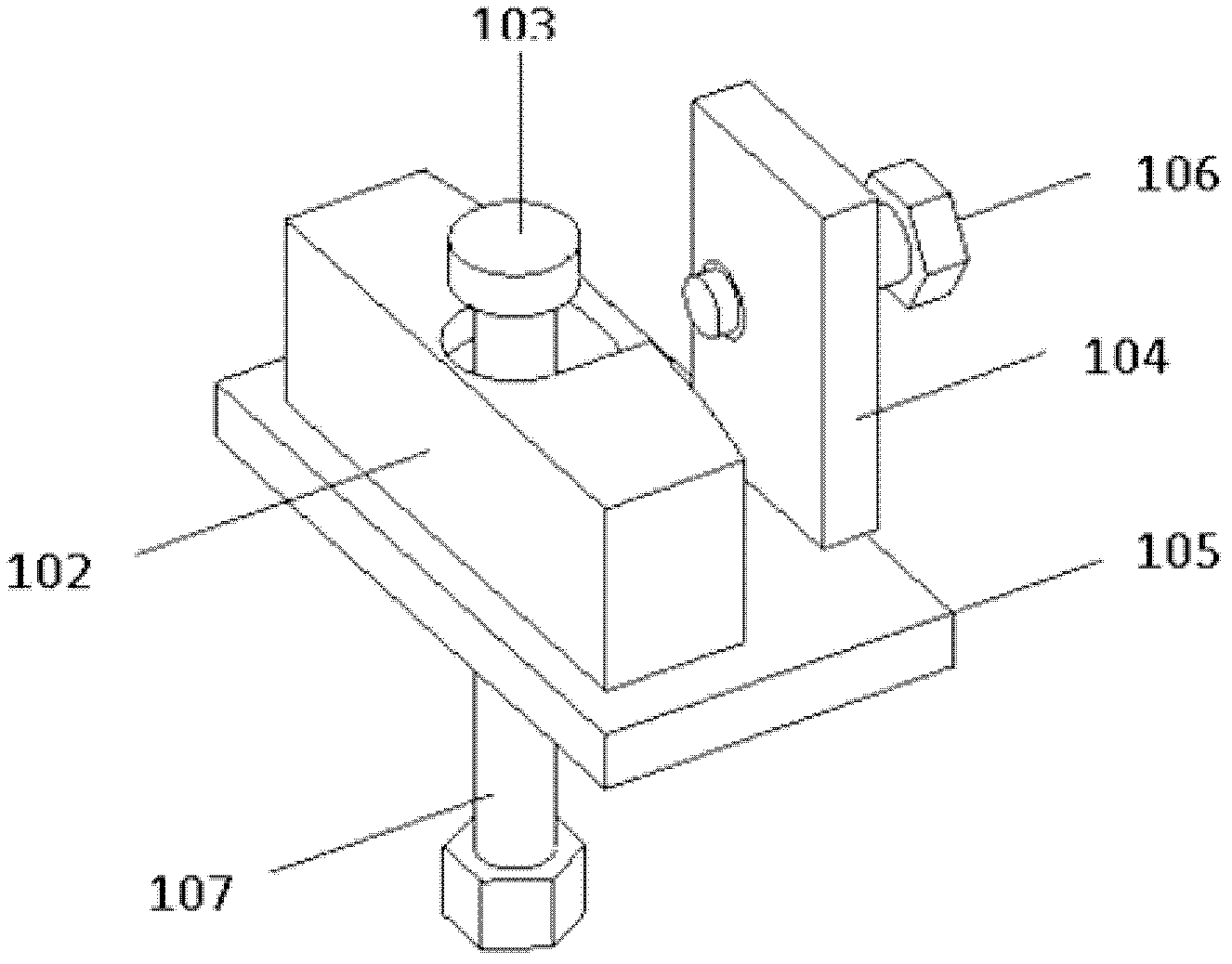

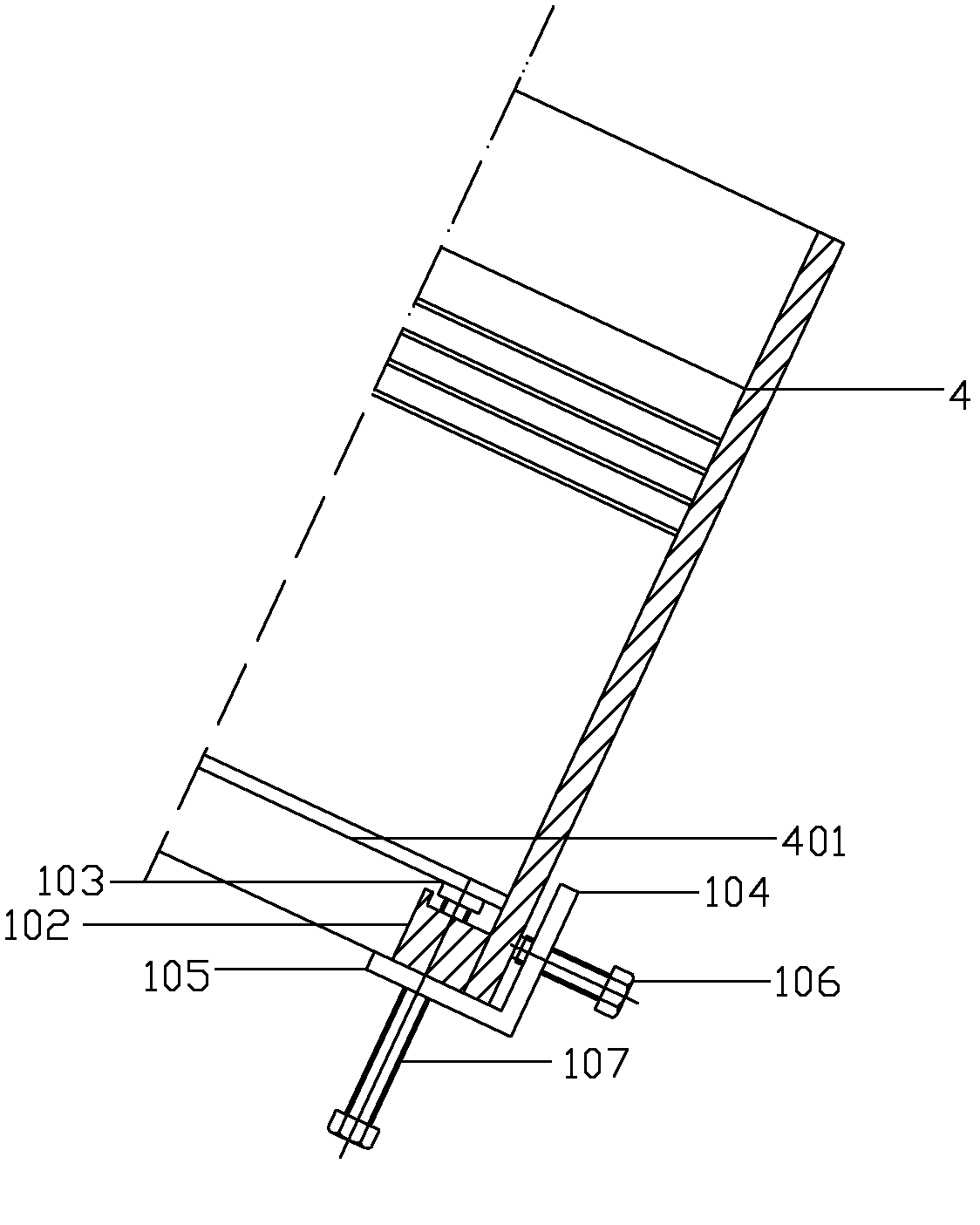

[0038] The tool for replacing the large-end bearing shell of a diesel engine connecting rod of a million-kilowatt nuclear power plant of the present invention includes a piston positioning adjustment tool 1 on the main connecting rod side and a positioning tool 2 for the piston connecting rod assembly on the auxiliary connecting rod side. Among them, the main connecting rod side piston positioning adjustment tool 1 includes a base 101, a clamping part 102 arranged on the base 101 and matched with the inner diameter of the main connecting rod cylinder 3, and a clamping part 102 movably arranged on the clamping part 102. The upper jacking part 103.

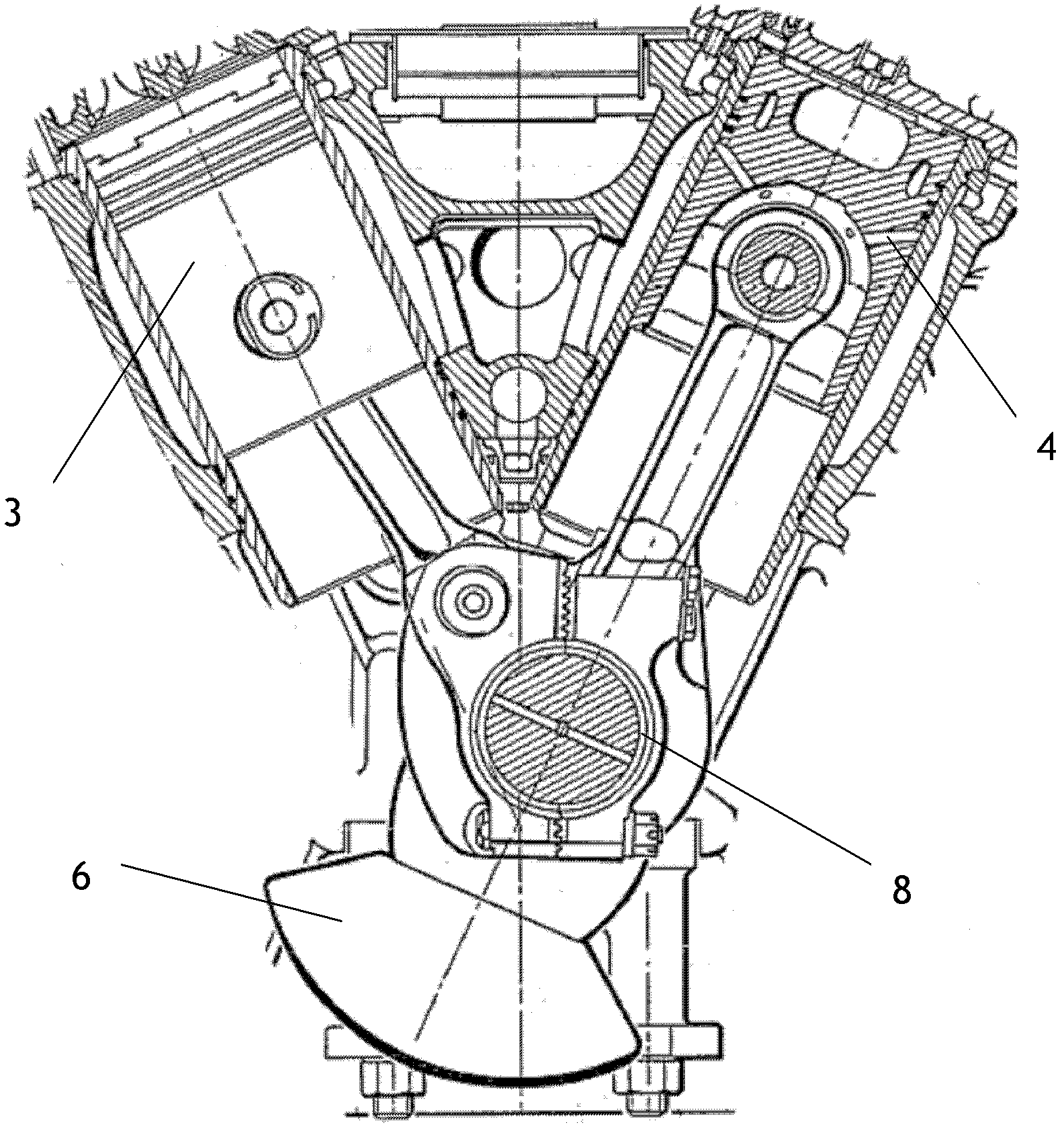

[0039] like figure 1 As shown, usually, the weight of the piston and connecting rod assembly of a diesel engine is fully supported on the crankshaft. If you want to solve the problem of replacing the connecting rod bearing bush 8 directly through the observation hole without disassembling the cylinder head and other related accessor...

Embodiment 2

[0048] A method for replacing the big end bearing bush of a diesel engine connecting rod of a million kilowatt nuclear power plant, comprising the following steps:

[0049] 1) Rotate the balance block 6 of the diesel engine crankshaft to the appropriate position at the lower part of the cylinder liner of the auxiliary connecting rod cylinder 3, remove the main and auxiliary connecting rod fastening bolts, the anti-loosening wire and the cotter pin, then keep one of the fastening bolts, and remove the rest The fastening bolts 7 connecting the big ends of the main and auxiliary connecting rods;

[0050] 2) Install the piston positioning adjustment tool 1 on the main connecting rod side;

[0051] 3) Install the auxiliary connecting rod side piston connecting rod assembly positioning tool 2 between the diesel engine crankshaft balance block 6 and the auxiliary connecting rod cylinder 3;

[0052] 4) Rotate the horizontal positioning jack 106 until one end of the horizontal positio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com