Injection molding machine

A technology of injection molding machine and molding device, applied in the direction of static electricity, electrical components, etc., can solve the problems of unstable quality, many defective products, high defective rate, etc., achieve stable static removal effect, reduce production cost, and improve the yield of good products.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

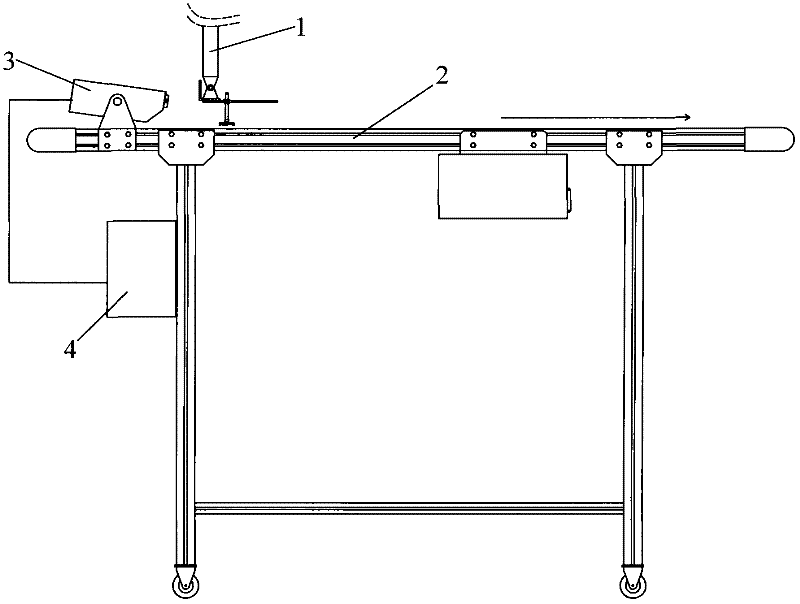

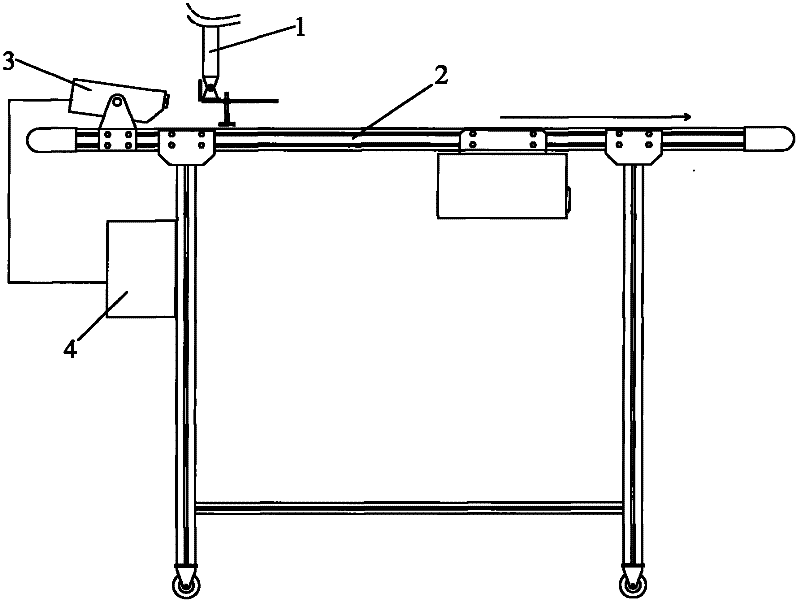

[0014] Injection molding machine, including frame, injection molding device and molding device, the side of the molding device is arranged with a conveyor, such as figure 1 As shown, there is a product input arm 1 above the conveyor 2, and an ionized air nozzle 3 is installed at the end position of the feeding end of the conveyor 2, and the ionized air nozzle 3 faces the conveyor belt running direction of the conveyor, and the ionized air nozzle 3 is connected to Ionized air generator4. A gas control switch is installed on the ionized air nozzle 3, and the gas control switch is connected to the control box through a control line. The ionized air generator 4 produces ionized air, which supplies the ionized air nozzle 3, and the ionized air nozzle 3 is provided with a spout, and the spout is used to spray ionized air to the product on the conveyor, and the ionized air is sprayed on the processed object (product) to Remove the dust adhering to the product, and perform electrosta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com