The method of post-treatment of pcb board after spraying tin

A technology of PCB boards and tin-sprayed boards, applied in the direction of electrical components, printed circuit manufacturing, printed circuits, etc., can solve the problems that the cooling efficiency of tin-sprayed boards cannot be guaranteed, and affect production capacity, etc., so as to improve production capacity, product quality, and strong applicability , the effect of improving the utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

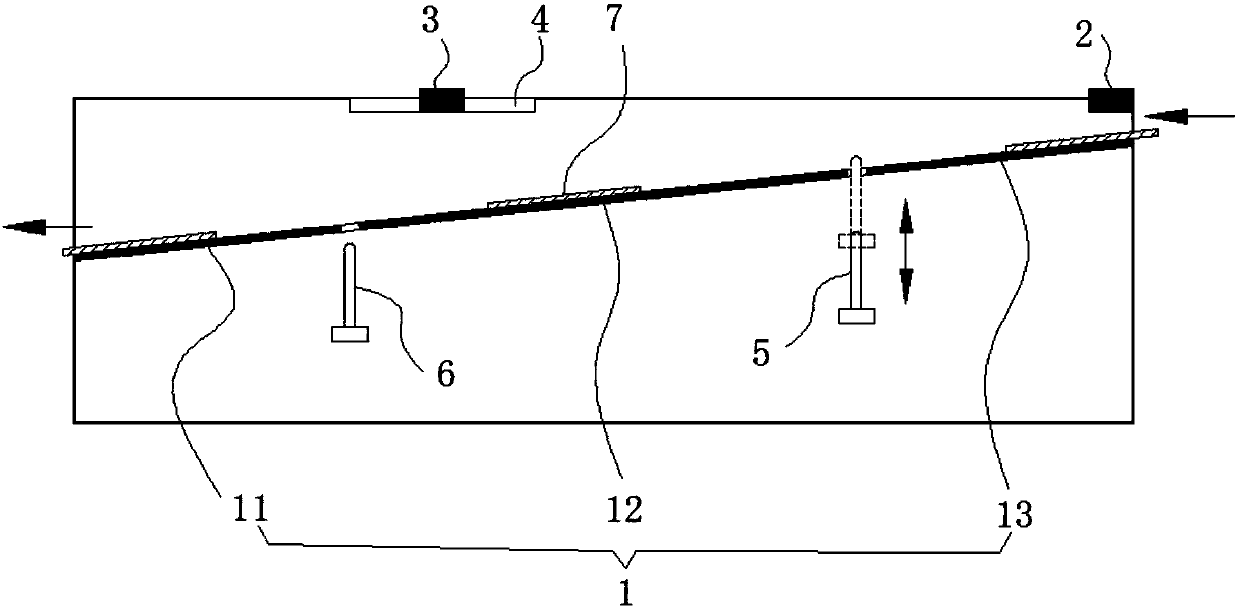

[0020] The post-treatment method of a kind of PCB board tin spraying of the present invention is to carry out on a gas floating bed, and the structure of the gas floating bed is as follows: figure 1 As shown, a slide rail 4 , a first inductor 2 , a second inductor 3 , a first pin baffle 5 , a second pin baffle 6 and a swash plate 1 are provided. The inclined plate 1 is provided with a pre-cooling section 13 , a cooling section 12 and a plate-out section 11 sequentially from front to back. The first sensor 2 is installed above the front end of the pre-cooling section 13, and the first sensor 2 is used to monitor the size information of the tin plate 7, and transmit this information to the control center (not shown in the figure) of the gas floating bed. The second inductor 3 is located above the cooling section 12, and the two ends of the second inductor 3 are connected to the slide rails 4 on both sides of the gas floating bed, and the second inductor 3 is used to monitor the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com