The production method of 2,6-dimethoxynaphthalene

A technology of dimethoxynaphthalene and a production method is applied in the directions of ester reaction preparation of ether, ether preparation, organic chemistry, etc., can solve the problems of long reaction time and low yield, etc., and achieves low reaction condition requirements and high product yield. , the effect of simple process route

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

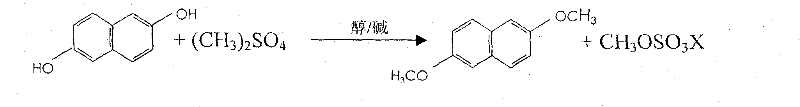

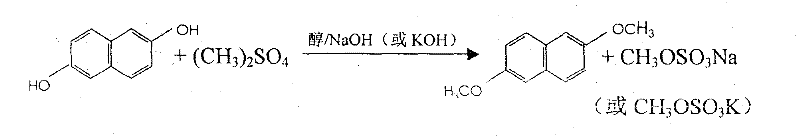

[0014] A kind of production method of 2,6-dimethoxynaphthalene, 2,6-dihydroxynaphthalene is dissolved in alcoholic solvent (such as methyl alcohol, ethanol, isopropanol), under alkaline condition (add alkali solution for Potassium hydroxide or sodium hydroxide) slowly add dimethyl sulfate solution and react at 20-70°C (such as 20°C, 30°C, 40°C, 50°C, 60°C, 70°C) for 3-6 Hour (as 3, 3.5, 4, 4.5, 5, 5.5, 6 hours) generates 2,6-dimethoxynaphthalene, and its reaction formula is:

[0015]

[0016] The amount of alcohol solvent is based on the complete dissolution of the raw material 2,6-dihydroxynaphthalene, the purity of the used 2,6-dihydroxynaphthalene is ≥98%, and the concentration of sodium hydroxide or potassium hydroxide solution is 15-45% (such as 15%, 20%, 25%, 30%, 35%, 40%, 45%), the molar ratio of 2,6-dihydroxynaphthalene and dimethyl sulfate is 1: 2.8, and the 2 , The average yield of 6-dimethoxynaphthalene was 70.1%.

Embodiment 2

[0018] The molar ratio of 2,6-dihydroxynaphthalene and dimethyl sulfate is 1: 3.0, all the other are the same as in Example 1, and the average yield of 2,6-dimethoxynaphthalene generated by the reaction is 85.4%.

Embodiment 3

[0020] The molar ratio of 2,6-dihydroxynaphthalene and dimethyl sulfate is 1: 3.5, all the other are the same as in Example 1, and the average yield of 2,6-dimethoxynaphthalene generated by the reaction is 86.2%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com