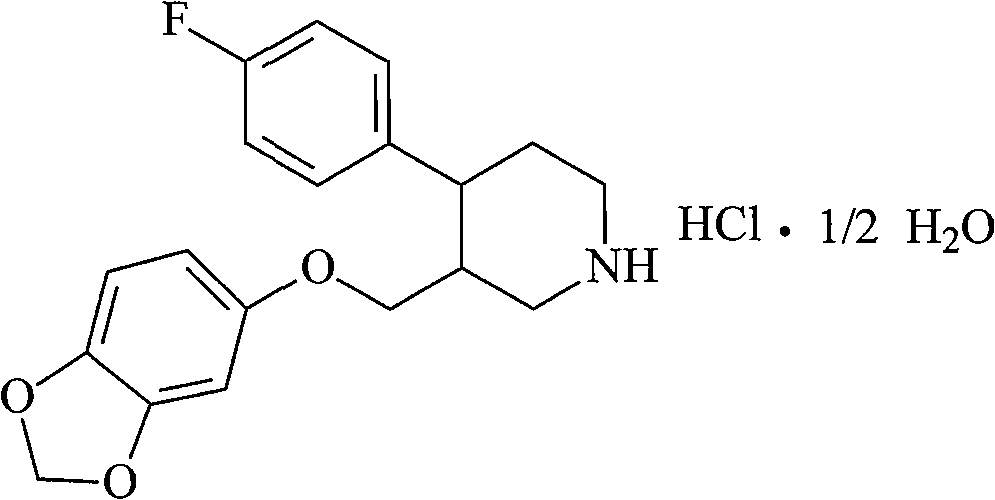

Paroxetine hydrochloride compound and preparation method thereof

A technology for paroxetine hydrochloride and a compound, applied in the field of medicine, can solve problems such as low purity of paroxetine hydrochloride, and achieve the effects of easy industrial production, easy control, and improved product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Accurately weigh 10 g of paroxetine hydrochloride raw material with a purity of 92.3% (Beijing Wansheng Pharmaceutical Co., Ltd., H20093150) and dissolve it in 50 ml of methanol, stir to make it completely dissolve, filter with suction, discard solid impurities, and collect the filtrate.

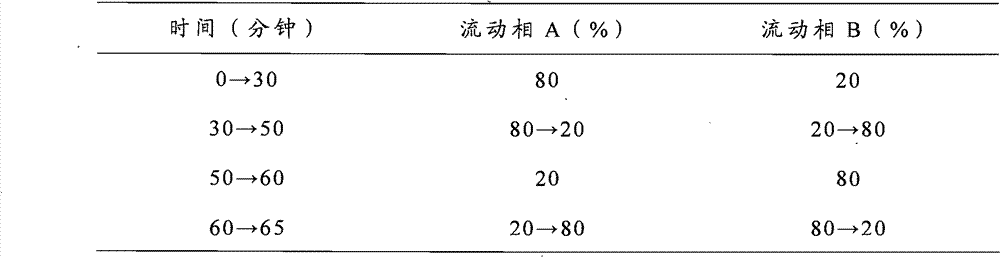

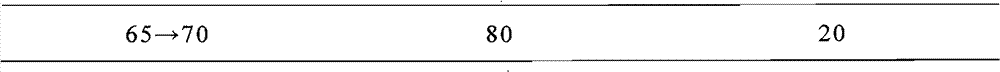

[0041] The methanol solution containing paroxetine hydrochloride is filled to a particle size of 75-165 μm and a pore size of A fine-pore silica gel column, then pumped into a mixed solvent of methanol and water with a volume ratio of 7:1 for elution, the column temperature is room temperature, and the flow rate is 1.2ml / min, and the elution site with a paroxetine hydrochloride content greater than 90% is collected. Concentrate under reduced pressure at 30°C at 0.1 MPa, and collect the concentrate.

[0042] Raise the methanol aqueous solution of paroxetine hydrochloride to 80°C, add 0.05M dilute hydrochloric acid aqueous solution accounting for 2 times its volume, adjust the pH value...

Embodiment 2

[0047] Accurately weigh 10 g of expired paroxetine hydrochloride raw material with a purity of 85.6% (Zhejiang Huahai Pharmaceutical Co., Ltd., H20031105) and dissolve it in 200 ml of methanol, stir to make it completely dissolve, filter with suction, discard solid impurities, and collect the filtrate.

[0048] The methanol solution containing paroxetine hydrochloride is filled to a particle size of 85-165 μm and a pore size of A fine-pore silica gel column, then pumped into a mixed solvent of methanol and water with a volume ratio of 6:1 for elution, the column temperature is room temperature, and the flow rate is 1.4ml / min, and the elution site where the paroxetine hydrochloride content is greater than 88% is collected, Concentrate under reduced pressure at 40°C at 0.08MPa, and collect the concentrate.

[0049] Raise the methanol aqueous solution of paroxetine hydrochloride to 75°C, add 0.01M dilute hydrochloric acid aqueous solution accounting for 1.5 times its volume, adj...

Embodiment 3

[0051] Accurately weigh 10 g of expired paroxetine hydrochloride raw material (Zhejiang Jianfeng Pharmaceutical Co., Ltd., H20040532) with a purity of 82.1% and dissolve it in 100 ml of methanol, stir to make it completely dissolve, filter with suction, discard solid impurities, and collect the filtrate.

[0052] The methanol solution containing paroxetine hydrochloride is filled to a particle size of 70-150 μm and a pore size of A fine-pore silica gel column, then pumped into a mixed solvent of methanol and water with a volume ratio of 5:1 for elution, the column temperature is room temperature, and the flow rate is 1.5ml / min, and the elution site where the paroxetine hydrochloride content is greater than 85% is collected, Concentrate under reduced pressure at 0.1MPa at 35°C, and collect the concentrate.

[0053] Raise the methanol aqueous solution of paroxetine hydrochloride to 70°C, add 0.008M dilute hydrochloric acid aqueous solution accounting for 3 times its volume, adj...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com