Single-layer plane cable net glass curtain wall self leveling construction method based on form finding analysis

A glass curtain wall and construction method technology, which is applied in the direction of walls, building materials processing, building components, etc., can solve problems such as large production safety hazards, large residual force on the glass surface, and difficult construction, so as to save construction costs and improve operability And the effect of strong applicability and reducing the difficulty of construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0058] The present invention will be described in detail below in conjunction with the accompanying drawings.

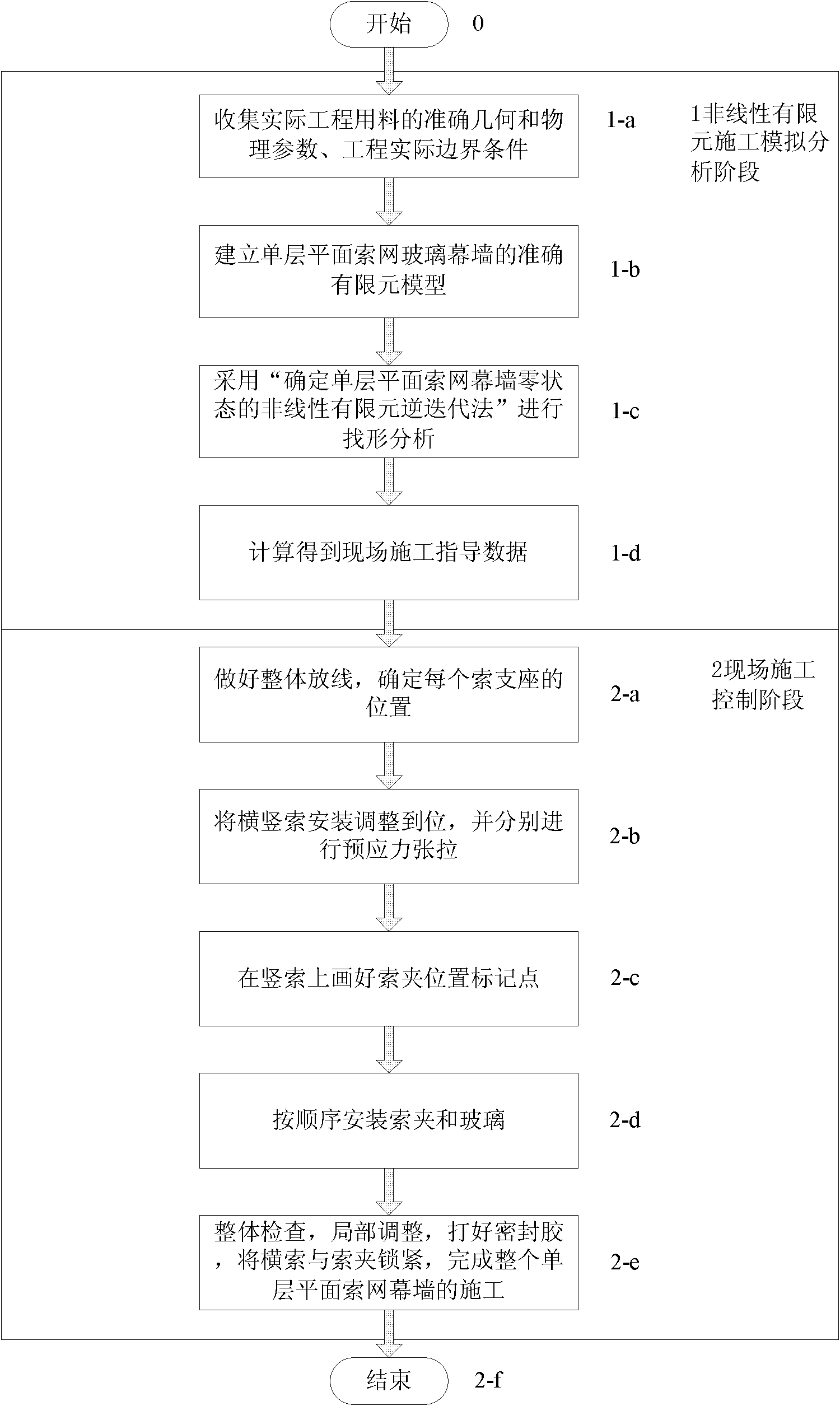

[0059] The flow chart of the self-straightening construction method of single-layer plane cable net glass curtain wall based on form-finding analysis of the present invention is as follows figure 1 As shown, it has the following steps:

[0060] 1) Nonlinear finite element construction simulation analysis stage:

[0061] a) Collect accurate geometric and physical parameters of actual engineering materials and actual engineering boundary conditions;

[0062] b) Establish an accurate finite element model of the single-layer planar cable-net glass curtain wall according to the collected actual parameters;

[0063] c) Using "Nonlinear finite element inverse iteration method to determine the zero state of single-layer planar cable-net curtain wall" to conduct form-finding analysis to determine the actual zero state, initial state and design forming state of single-layer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com