Lift-drag type vertical axis wind driven generator based on overrunning combined mechanism

A technology of wind power generator and vertical axis, which is applied in the direction of wind power generator components, wind power engine, wind power motor combination, etc., which can solve the problems of low wind power generation efficiency, low reliability and poor stability, so as to improve the start-up performance and realize The effect of energy harvesting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

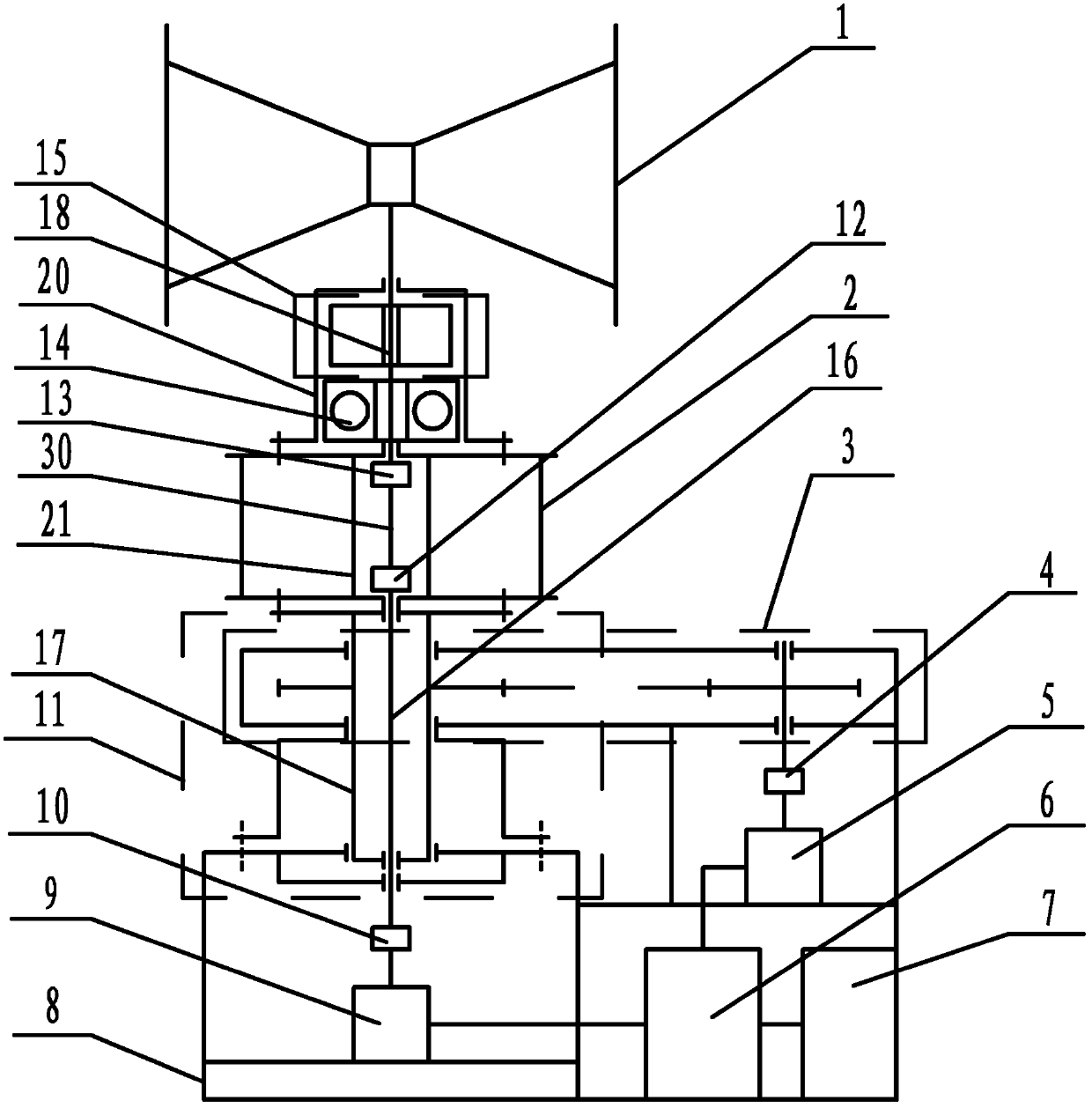

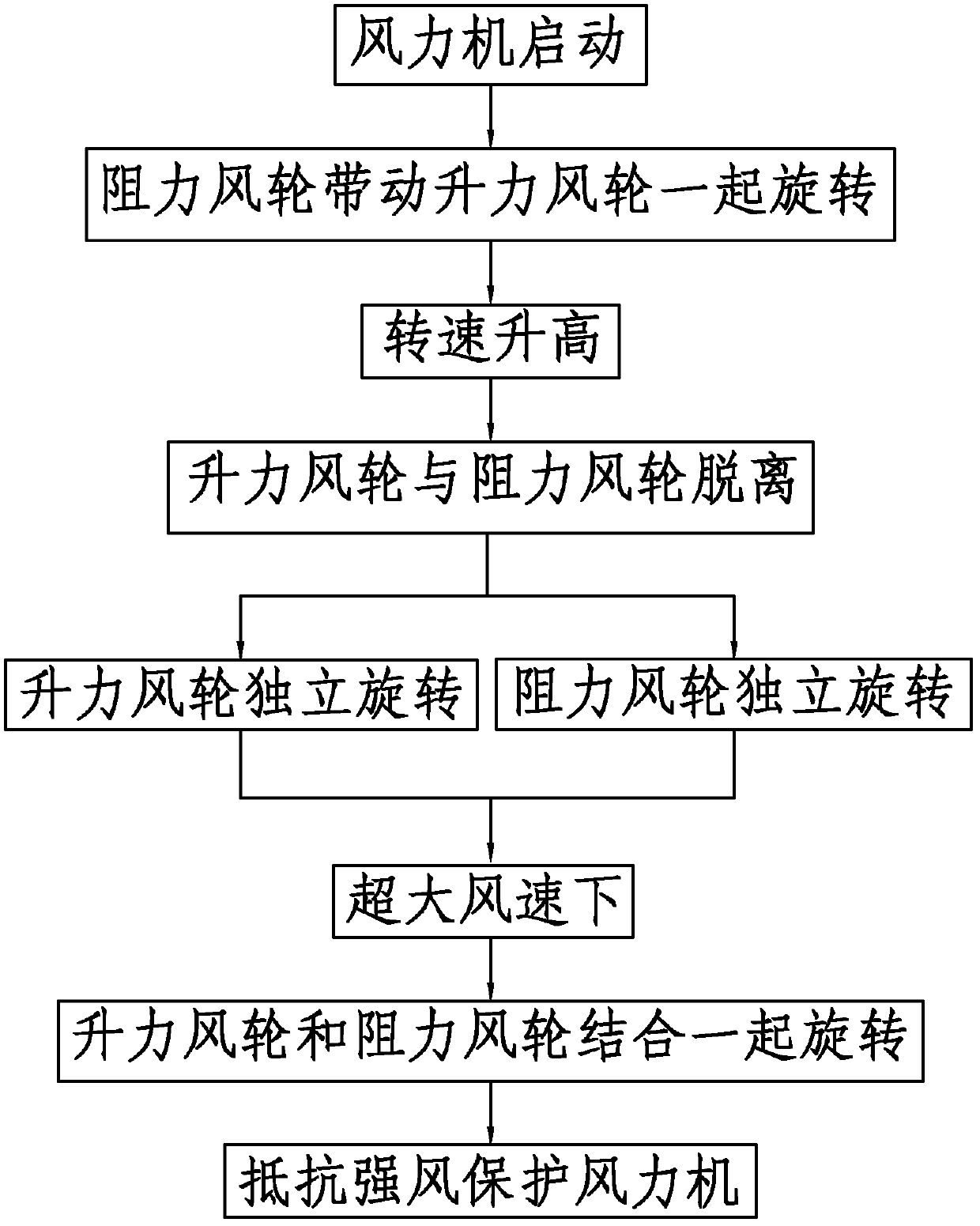

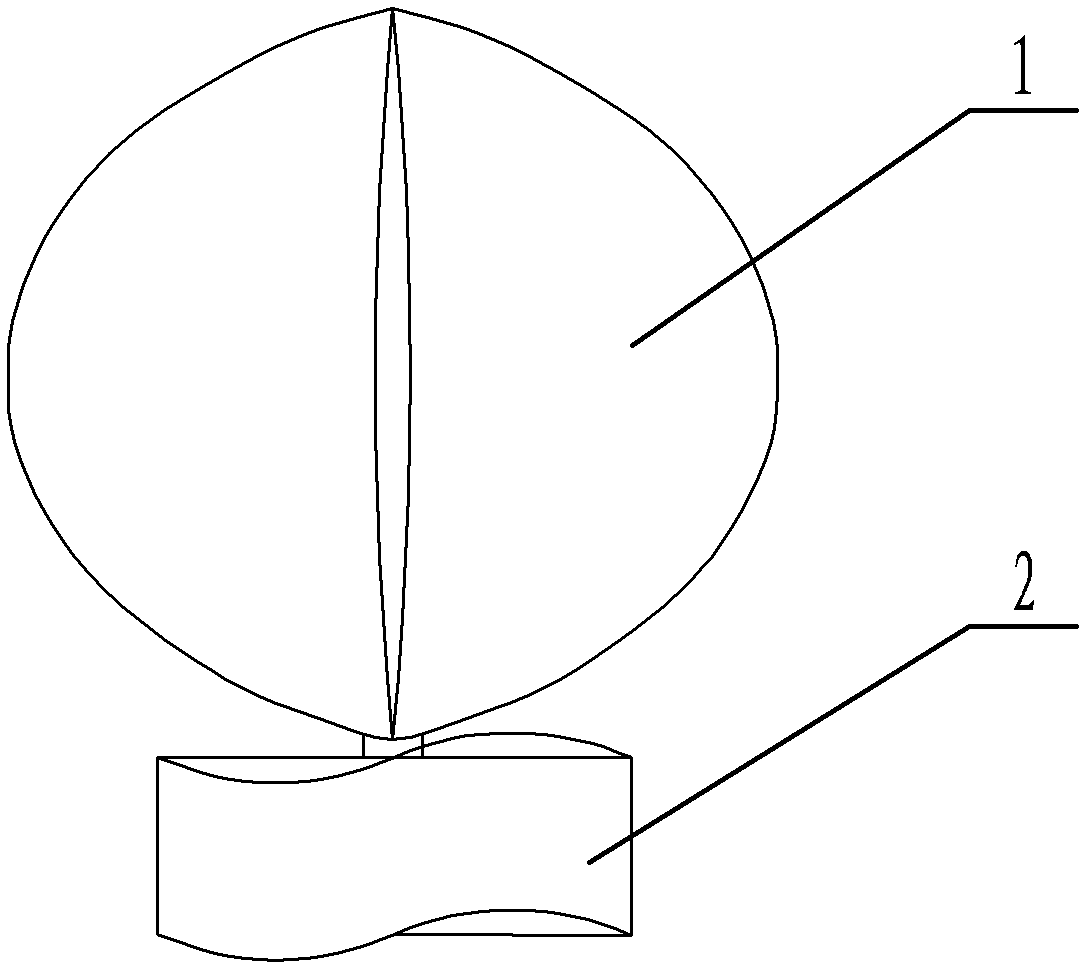

specific Embodiment approach 1

[0022] Specific implementation mode one: combine figure 1 and Figure 5 to Figure 10To illustrate, the lift-drag vertical axis wind power generator based on the transcending composite mechanism in this embodiment includes a lift wind wheel 1, a drag wind wheel 2, an overrunning compound mechanism 15, and a shaft center shaft transmission. Device 11, resistance wind wheel speed increasing device 3, lift wind turbine generator 9, resistance wind turbine generator 5, rectification controller 6, energy storage device 7, first coupling 13, second coupling 12, the first Three couplings 10, the fourth coupling 4, the first rolling bearing 14, the first resistance wind rotor shaft 20, the second resistance wind rotor shaft 21, the first lift wind rotor shaft 18, the second lift wind rotor shaft 30 and the fixed support 8 The first resistance wind wheel shaft 20 and the second resistance wind wheel shaft 21 are all provided with a hollow cavity, the resistance wind wheel 2 is installe...

specific Embodiment approach 2

[0029] Specific implementation mode two: combination figure 1 and Figure 5 ~ Figure 7 Illustrate that the overriding composite mechanism 15 in this embodiment includes a combination mechanism, a separation mechanism, an outer sleeve 32 and an inner sleeve 33; connection (connected by flat key 22 in this embodiment), the outer sleeve 32 is set on the inner sleeve 33, the outer sleeve 32 is arranged in the hollow cavity of the first resistance wind wheel shaft 20, and the outer sleeve 32 is connected with the first resistance wind wheel shaft 20 (in this embodiment In the method, screw 23 is used for connection); the separation mechanism includes two balls 34 and two first springs 35, and two gaps 36 are arranged on the outer wall of the inner sleeve 33, and the two gaps 36 are symmetrical with respect to the center line of the inner sleeve 33 Setting, each notch 36 is provided with a ball 34 and a first spring 35, one end of each first spring 35 is connected with the correspo...

specific Embodiment approach 3

[0033] Specific implementation mode three: combination Figure 7 To illustrate, the number of slider grooves 39 in this embodiment is 4-8. The exact amount is determined by the friction torque. Others are the same as in the second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com