New liquid injection rubber expansion valve

A technology of rubber expansion and liquid injection, applied in the direction of control valve, valve device, functional valve type, etc., can solve the problems of inability to meet the needs of large-scale use, high manufacturing cost of alloy steel materials, complicated operation procedures, etc., to achieve the opening pressure and Stable non-return effect, improved yield and flexible application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

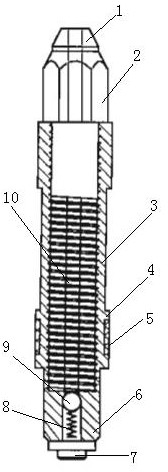

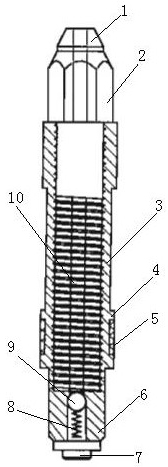

Image

Examples

Embodiment Construction

[0014] The specific technological process of the novel liquid injection rubber expansion valve is as follows:

[0015] 1) The whole is composed of check valve, screw rod, aluminum sleeve, rubber ring, injection head, gasket, liquid outlet, etc., while the check valve is composed of three parts: valve body, spring and steel ball, and its seat is processed in On the valve body, the cracking pressure is achieved by controlling the pre-compression of the spring by adopting necking technology, that is, putting the ball steel and the spring into the valve body at one time, and then shrinking the valve body to control the degree of necking. The pre-compression of the spring, so as to realize the stability of the opening pressure;

[0016] 2) Drill a pre-drilled hole corresponding to the diameter of the product on the wall, and put the product into the pre-drilled hole (the valve body faces inward). Since the injection head and the valve body are connected by threads, use an electric ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com