Device for automatically detecting flatness and thickness of substrates and separating substrates

A technology for automatic detection and flatness, applied in measuring devices, optical devices, sorting, etc., can solve problems such as unfavorable production, substrate contamination, low efficiency and detection accuracy, etc., to improve production efficiency, improve yield, The effect of increasing the overall value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

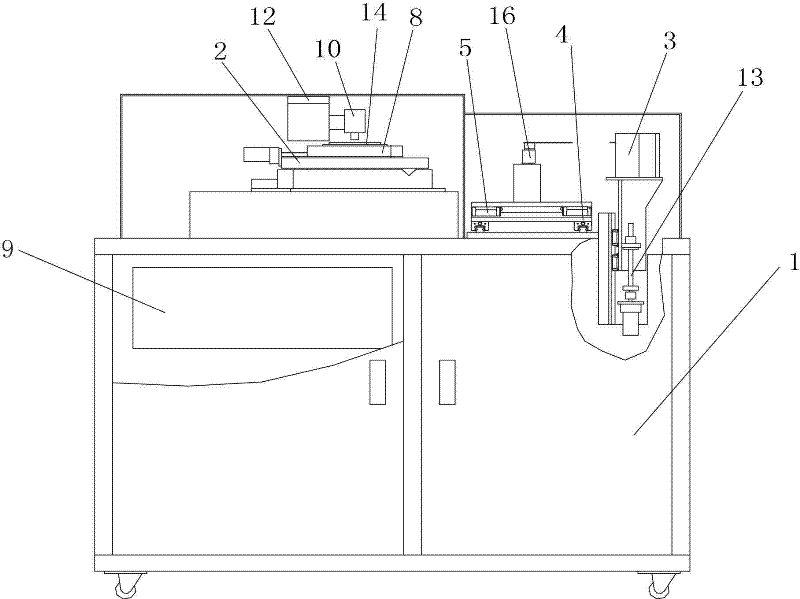

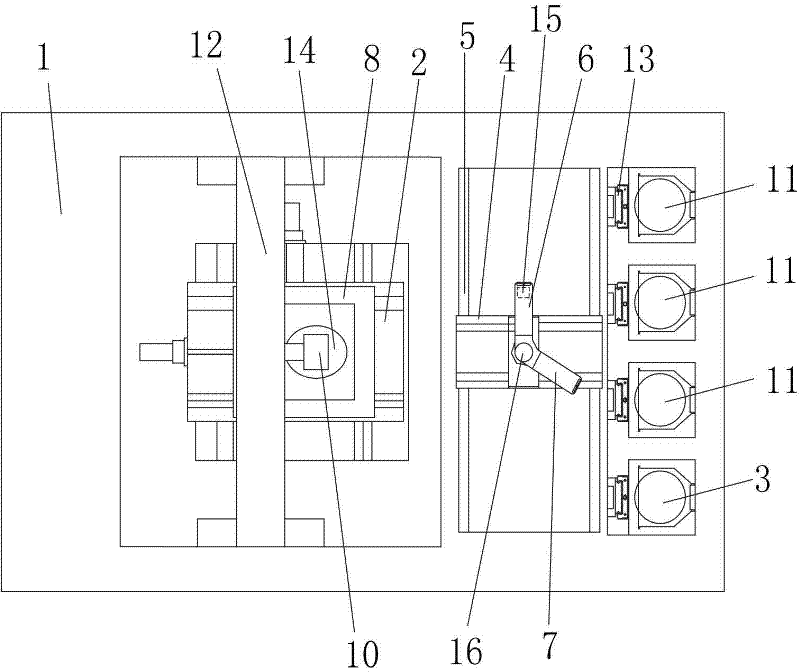

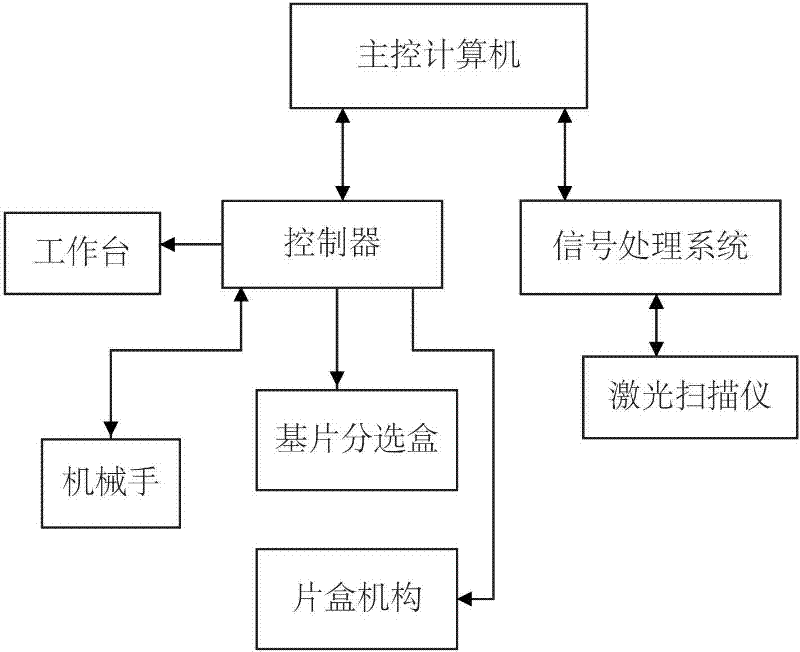

[0018] according to figure 1 , figure 2 , image 3 , the present invention comprises a base 1, a workbench 2, a cassette mechanism 3 for placing substrates to be tested 14, a manipulator 16 capable of moving through the X guide rail 4 and the Y guide guide 5 and capable of rotating itself, the manipulator 16 It is composed of an upper film arm 6 and a lower film arm 7; the workbench 2 is provided with a film support platform 8, and the workbench 2 and the manipulator 16 are respectively connected to the base 1, and also includes a computer control system 9 and a laser scanner 10 , the substrate sorting box 11, the computer control system 9 includes a main control computer, a signal processing system, a controller, the main control computer is connected with the controller through the RS-232 serial port connection, and the main control computer is connected with the controller through a signal The processing system is connected to the laser scanner 10, and the main control c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com