Soft Measurement Method of Turbine Steam Flow

A technology of steam flow and soft measurement, which is used in the measurement of flow/mass flow, liquid/fluid solid measurement, measurement devices, etc. It can solve the problems of inaccurate indication and long use time of flow meters, and achieve the effect of improving stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

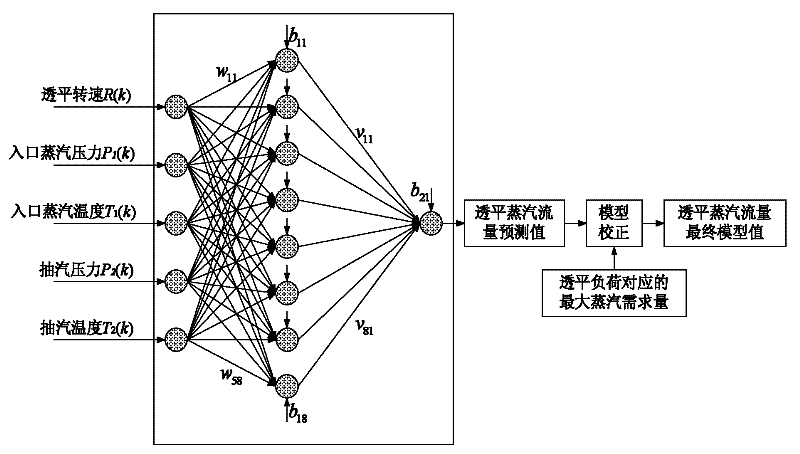

[0015] According to the tachometer for measuring the rotating speed of the turbine, the thermometer and the pressure gauge for measuring the steam at the inlet of the turbine and the extraction steam of the turbine; Accurate flow value. Using neural network technology, a soft measurement system for turbine steam flow is established. The soft measuring system is generally applicable to steam flow measurement using compressor turbines and pump turbines in ethylene plants.

[0016] Since the back propagation (BP, Back Propagation) neural network with a structure of more than three layers has the function of mapping any nonlinear function, here, a three-layer structure of the BP neural network is used to establish a soft sensor model of the turbine steam flow. Using the model variables selected above, construct the turbine steam flow neural network soft sensor model, such as figure 1 shown.

[0017] figure 1 Block Diagram of Turbine Steam Flow Neural Network Soft Sensor

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com