Capacitive vacuum pressure sensor

A pressure sensor and vacuum pressure technology, which is applied in the direction of fluid pressure measurement, vacuum gauge, and fluid pressure measurement using capacitance change, which can solve the problems of affecting the stability of sensor elements, easy to loose, and high manufacturing cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

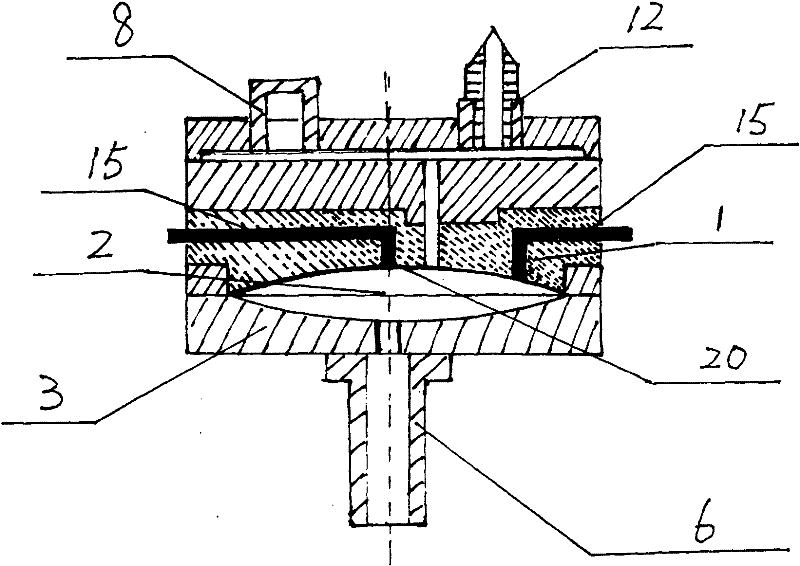

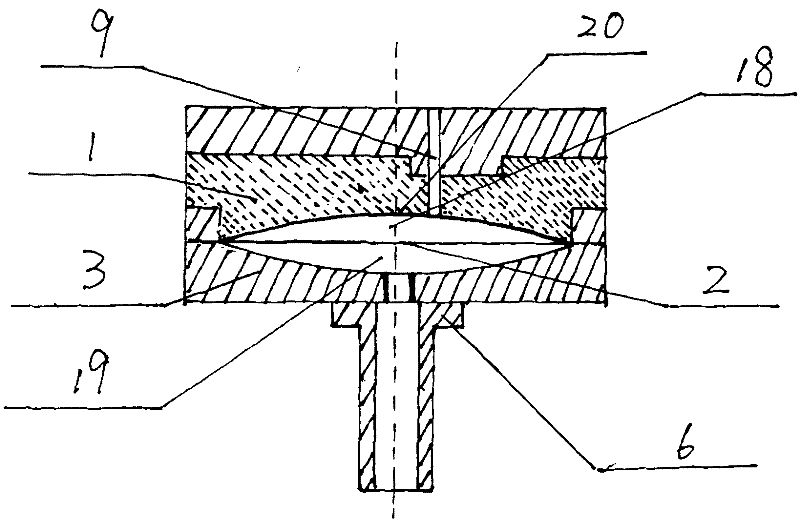

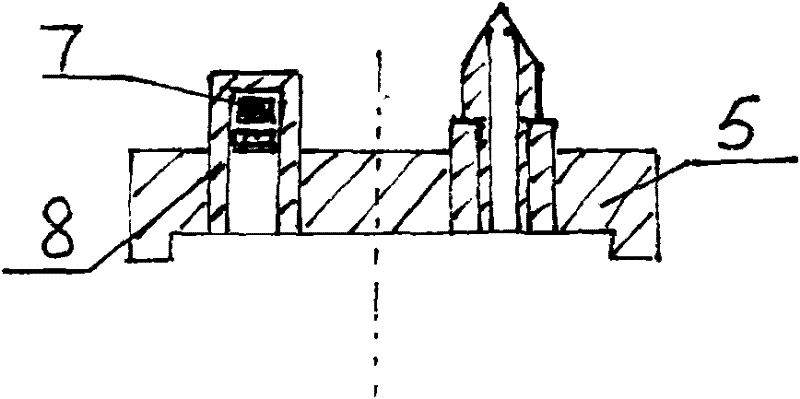

[0029] In order to manufacture a well-functioning sensor with the above characteristics, it is very important to follow the relevant manufacturing methods. In order to achieve this, a corrosion-resistant alloy is used as the base (4), and two alloy conductive wires (15) are built in. and porcelain tube air hole (9), choose a certain formula and weight of glass, place it in the base (4), and put it into a high-temperature sintering furnace for firing. Generally, after several hours at 900-1100°C, the glass is obtained Fully melted, cooled to about 600°C, kept warm for several hours, and cooled to room temperature with the furnace, the glass and the built-in alloy conductive wire (15), porcelain tube (9) and alloy base (4) were integrated into one , the synthetic piece of glass alloy that constitutes the sensor, through the grinding of the glass surface on the synthetic piece, a curved surface (17) with a certain depth is formed, after coating, plating or sputtering gold elements...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com