A Wavelength Beam Combiner Device with Brewster's Angle of Incidence

A technology of Brewster angle and beam combining mirror, which is applied in the field of semiconductor lasers, can solve the problems of difficult coating and low beam combining efficiency, and achieve the effects of reducing coating difficulty, improving beam combining efficiency, and reducing the number

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

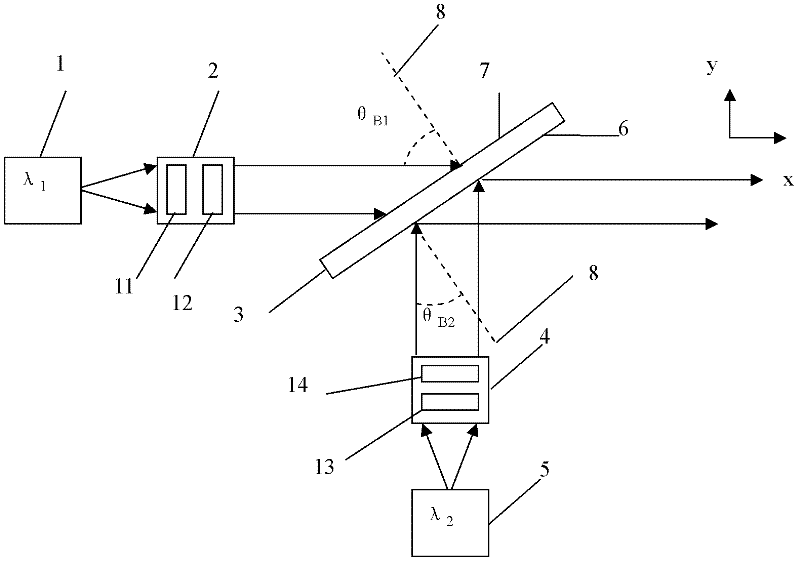

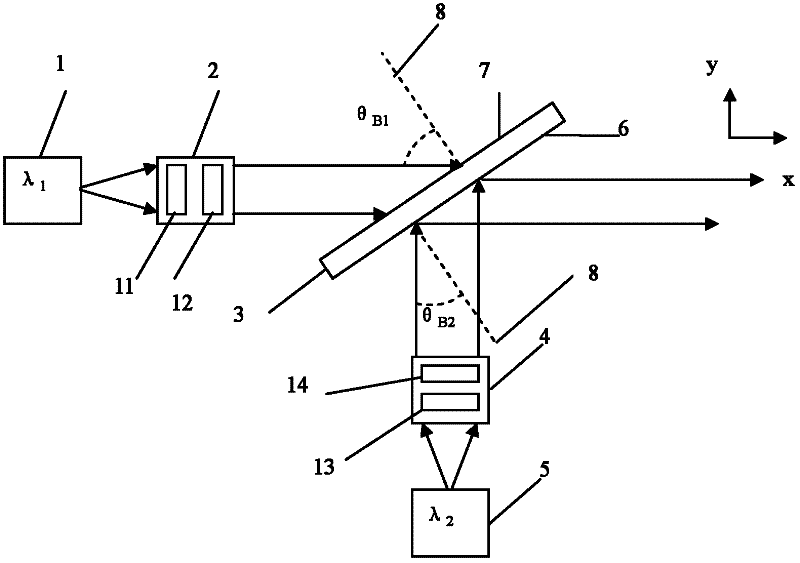

[0018] Embodiment 1: There are two stacks of semiconductor lasers, the output power of each stack is 600W, the output wavelengths are 808nm and 880nm respectively, and both are output in TE mode.

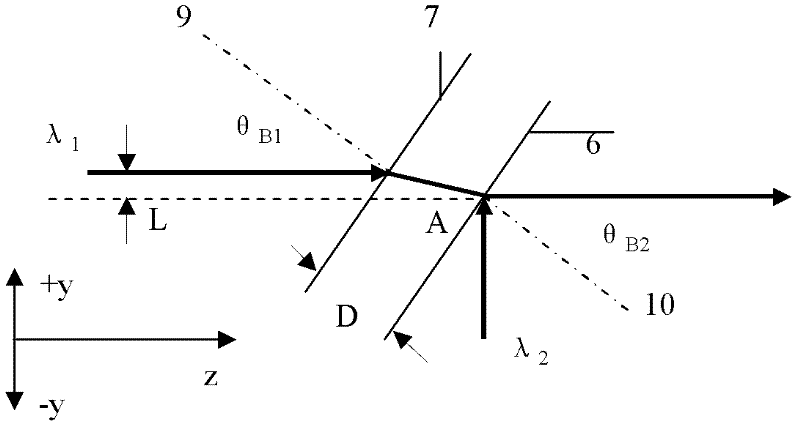

[0019] The substrate of the wavelength beam combiner is K9, the thickness D is 3mm, and the 880nm laser is selected as the transmitted light of the first laser, and the 808nm laser is reflected as the reflected light of the second laser. When the wavelength is 880nm, the refractive index of K9 is 1.509. According to Brewster's angle formula tan θ B1 =n 2 / n 1 Available, θ B1 = θ B2 =56.5°, L=1.4mm, then the coating requirement of the dichroic film is 880nm antireflection and 808nm high reflection under the condition of incident angle of 56.5°, and the values are set as 95% and 99% respectively.

[0020] Beam combining process: Firstly, each stack is collimated by fast and slow axis collimator mirrors, and each optical surface of the collimator mirrors is coated with an anti-re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com