Composite solar photovoltaic busbar and preparation method thereof

A solar photovoltaic and welding ribbon technology, which is applied in photovoltaic power generation, metal/alloy conductor, cable/conductor manufacturing, etc., can solve the problem of high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

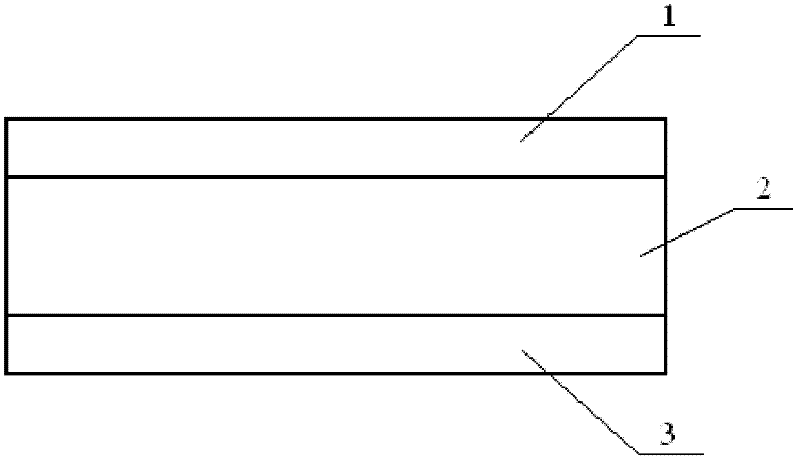

[0011] Specific implementation mode one: (please refer to the attached figure 1 ) The composite solar photovoltaic converging ribbon of this embodiment is a parallel three-layer composite structural strip composed of the first copper layer 1, the aluminum layer 2 and the second copper layer 3. The width of the composite structural strip is 2 mm to 62 mm, and the thickness is 0.1 mm. mm~0.25mm, wherein the aluminum layer 2 is located in the middle, the first copper layer 1 and the second copper layer 3 are respectively located on the upper and lower sides of the aluminum layer 2, and the thickness of the aluminum layer 2 accounts for 50% to 80% of the thickness of the composite structure strip %, the contact rate between the first copper layer 1 and the aluminum layer 2 is greater than 99%, and the contact rate between the second copper layer 3 and the aluminum layer 2 is greater than 99%.

[0012] This embodiment breaks through the technical preparation of soft copper to solve...

specific Embodiment approach 2

[0013] Embodiment 2: This embodiment differs from Embodiment 1 in that the width of the composite structure belt is 5 mm to 58 mm, and the thickness is 0.15 mm to 0.20 mm. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0014] Embodiment 3: This embodiment differs from Embodiment 1 in that the width of the composite structure belt is 30 mm and the thickness is 0.18 mm. Others are the same as in the first embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com