Amorphous thin film transistor and preparation method thereof

An active layer and gate dielectric technology, applied in the direction of transistors, semiconductor devices, electrical components, etc., can solve the problems that cannot meet the requirements of AM-FPD development, and achieve the effect of improving the stability of TFT

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

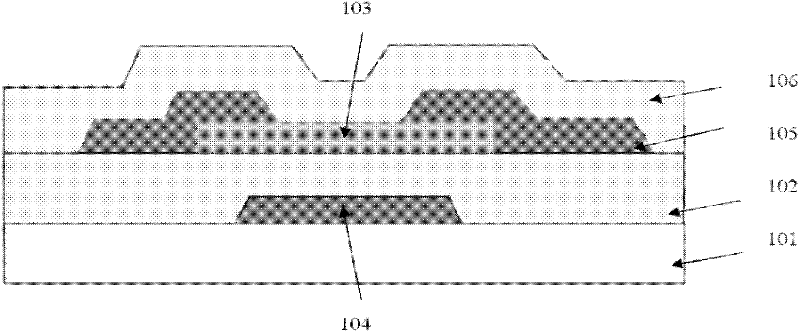

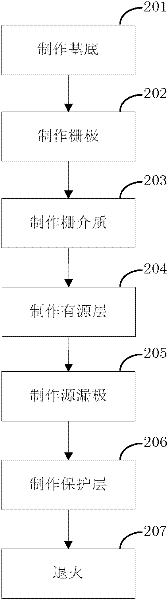

[0015] The present invention will be further described in detail below through specific embodiments in conjunction with the accompanying drawings.

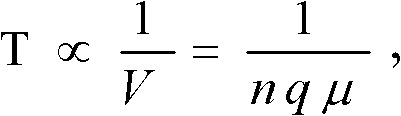

[0016] At present, the main technical problems to be solved by MOTFT are: first, improve the stability of EBS; second, improve the stability of UV light; third, improve μ. The technical solutions for solving the above problems in the embodiments of the present invention include: first, using the active layer with the optimal O content to improve the EBS stability of the MOTFT; second, using the MS process to continuously prepare the amorphous gate dielectric and the active layer process To improve the EBS stability of MOTFT; third, use Mg-doped active layer to improve the UV light stability of MOTFT; fourth, use Ga or Mg-doped In 2 o 3 As the active layer to prepare high μTFT; Fifth, improve the T of the ZnO active layer prepared by MS process S Or use the PLD process to prepare the ZnO active layer to prepare high μZnO TFT.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com