High-activity CaO-based bifunctional material as well as preparation method and application thereof

A dual-functional material, high-activity technology, applied in chemical instruments and methods, climate sustainability, sustainable manufacturing/processing, etc. Stable pore structure, strong cycle stability, and the effect of improving activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

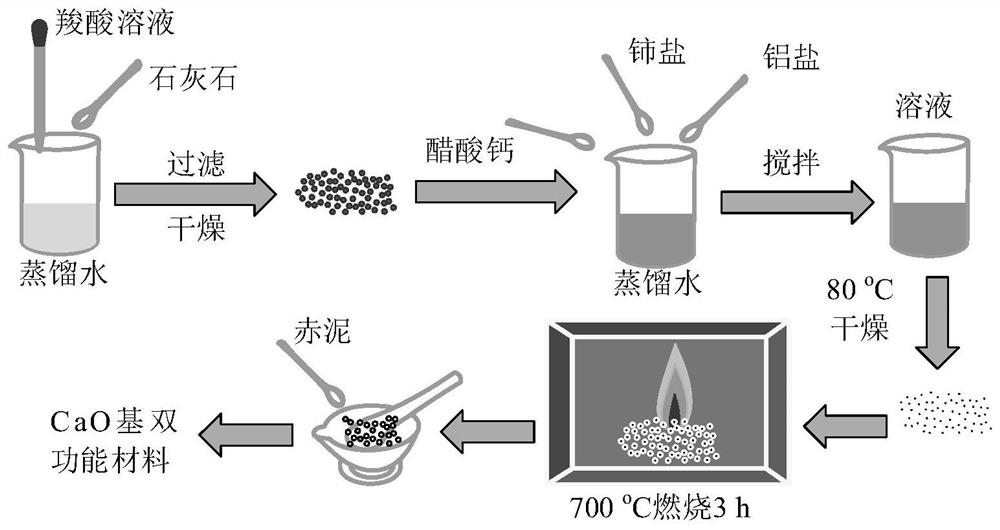

[0035] In one or some embodiments of the present disclosure, a method for preparing the above-mentioned highly active CaO-based bifunctional material is provided, including the following steps: (1) weighing limestone at room temperature, then adding distilled water, and stirring the mixture in a magnetic stirrer ;

[0036] (2) adding a carboxyl-containing solution to the stirred suspension, filtering the mixture to obtain a clear solution, and then drying it to obtain a solid material;

[0037] (3) Weigh the solid material obtained in step (2) at room temperature, add distilled water and stir until the solid material is completely dissolved; add aluminum salt and cerium salt to the solution at room temperature and stir until it is completely dissolved;

[0038] (4) Place the solution obtained in step (3) in a ventilated drying oven to dry, and obtain a solid material after complete drying;

[0039] (5) Combusting the solid material obtained in step (4) under an air atmosphere...

Embodiment 1

[0061] This example provides a highly active complex calcium-based CO 2 The preparation method of absorbent, specifically comprises the steps:

[0062] (1) Limestone and distilled water with a mass volume ratio of 4g:8mL were mixed in a beaker, and placed in a magnetic stirrer to stir for 10min;

[0063] (2) Add glacial acetic acid to the obtained suspension to form a mixed solution, the volume ratio of glacial acetic acid and distilled water is 1:2; after the mixture is stable, filter the mixed solution to obtain a clear solution, and dry it to obtain the solid material calcium acetate ;

[0064] (3) Weigh 10 g of calcium acetate prepared in step (2) at room temperature, add 200 mL of distilled water and stir until the calcium acetate is completely dissolved to obtain a uniform solution; add 1.505 g of cerium nitrate hexahydrate and 1.462 g of nonaqueous to the above calcium acetate solution Aluminum nitrate, the mixture is placed in a magnetic stirrer at room temperature a...

Embodiment 2

[0069] This embodiment provides a method for preparing a highly active composite CaO-based bifunctional material, which specifically includes the following steps:

[0070] (1) Mix limestone and distilled water with a mass volume ratio of 1g:8mL in a beaker, place it in a magnetic stirrer and stir for 10min;

[0071] (2) Add glacial acetic acid to the obtained suspension to form a mixed solution, the volume ratio of glacial acetic acid and distilled water is 1:2.5; after the mixture is stabilized, the mixed solution is filtered to obtain a clear solution, and the solid material calcium acetate is obtained after drying ;

[0072] (3) Weigh 10 g of calcium acetate prepared in step (2) at room temperature, add 150 mL of distilled water and stir until the calcium acetate is completely dissolved to obtain a uniform solution; add 1.505 g of cerium nitrate hexahydrate and 1.462 g of nonaqueous to the above calcium acetate solution Aluminum nitrate, the mixture is placed in a magnetic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com