Silicon-doped magnetron sputtering process for improving reliability of TaOx-based resistive random access memory

A technology of resistive variable memory and magnetron sputtering, which is applied in sputtering plating, metal material coating process, ion implantation plating, etc., which can solve the constraints of less read and write times, high operating voltage, operating voltage and durability The commercial application of devices and other issues, to achieve the effect of improving reliability, reducing operating voltage, and fast film deposition speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

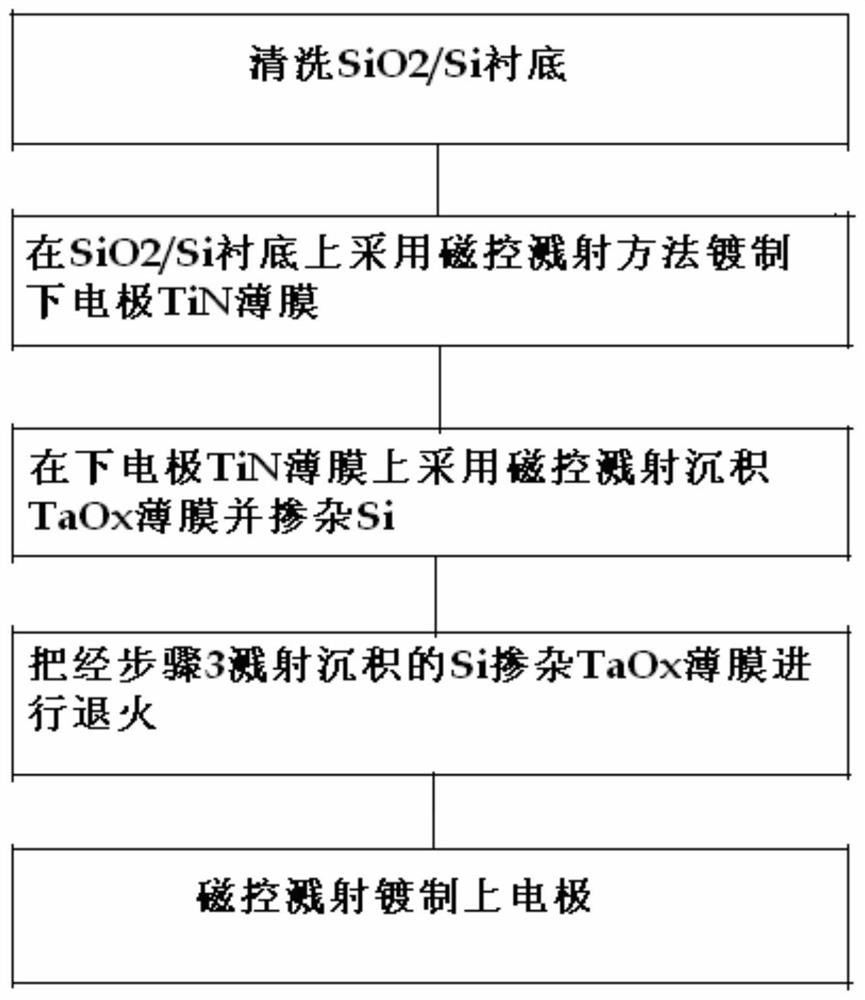

[0038] Such as figure 1 As shown, an improved TaO x The silicon-doped magnetron sputtering process for the reliability of the base resistive variable memory comprises the following steps:

[0039] Step 1. Clean SiO2 2 / Si substrate, specifically comprising the following sub-steps:

[0040] (a) SiO 2 Put the Si substrate in deionized water and ultrasonically clean it for 5 minutes;

[0041] (b) SiO cleaned by substep (a) 2 Put the Si substrate in acetone and ultrasonically clean it for 5 minutes;

[0042] (c) SiO cleaned by substep (b) 2 Put the Si substrate in absolute ethanol and ultrasonically clean it for 5 minutes;

[0043] (d) SiO cleaned by substep (c) 2 / Si substrate is rinsed with deionized water, and then dried with N2 gas;

[0044] Step 2, on SiO 2 On the Si substrate, the TiN film of the lower electrode is plated by the magnetron sputtering method, which specifically includes the following sub-steps:

[0045] (a) SiO cleaned in step 1 2 / Si substrate is p...

Embodiment 2

[0060] Step 1 to step 4 in this embodiment are identical to step 1 to step 4 in embodiment 1;

[0061] Step 5, plating the Pt upper electrode by magnetron sputtering, specifically includes the following sub-steps:

[0062] (a) Si-doped TaO annealed in step 4 x The film is placed in a magnetron sputtering vacuum chamber;

[0063] (b) Evacuate the vacuum chamber to 5×10 -4 Pa, the substrate temperature is room temperature, argon gas is introduced into the vacuum chamber, the flow rate is 10sccm, the power is adjusted to 18W, the pre-sputtering is 10min and the formal sputtering is 40min, the thickness of the deposited Pt upper electrode is 150nm, and the current-voltage test curve Such as Figure 5 shown.

Embodiment 3

[0065] Step 1 to step 4 in this embodiment are identical to step 1 to step 4 in embodiment 1;

[0066] Step 5, plating the Al upper electrode by magnetron sputtering, specifically includes the following sub-steps:

[0067] (a) Si-doped TaO annealed in step 4 x The film is placed in a magnetron sputtering vacuum chamber;

[0068] (b) Evacuate the vacuum chamber to 5×10 -4 Pa, the substrate temperature is room temperature, argon gas is introduced into the vacuum chamber, the flow rate is 12sccm, the power is adjusted to 18W, the pre-sputtering is 10min and the formal sputtering is 42min, the thickness of the upper electrode deposited on Al is 150nm, and the current-voltage test curve Such as Figure 6 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com