Large-scale dual-rotor direct-drive permanent magnet wind turbine and its generator set

A technology for wind turbines and wind turbines, which is applied to wind power generation, the shape/style/structure of winding conductors, electrical components, etc. Expensive, increase the cost of use and other issues, to achieve the effect of easy machine automation, weight reduction, cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

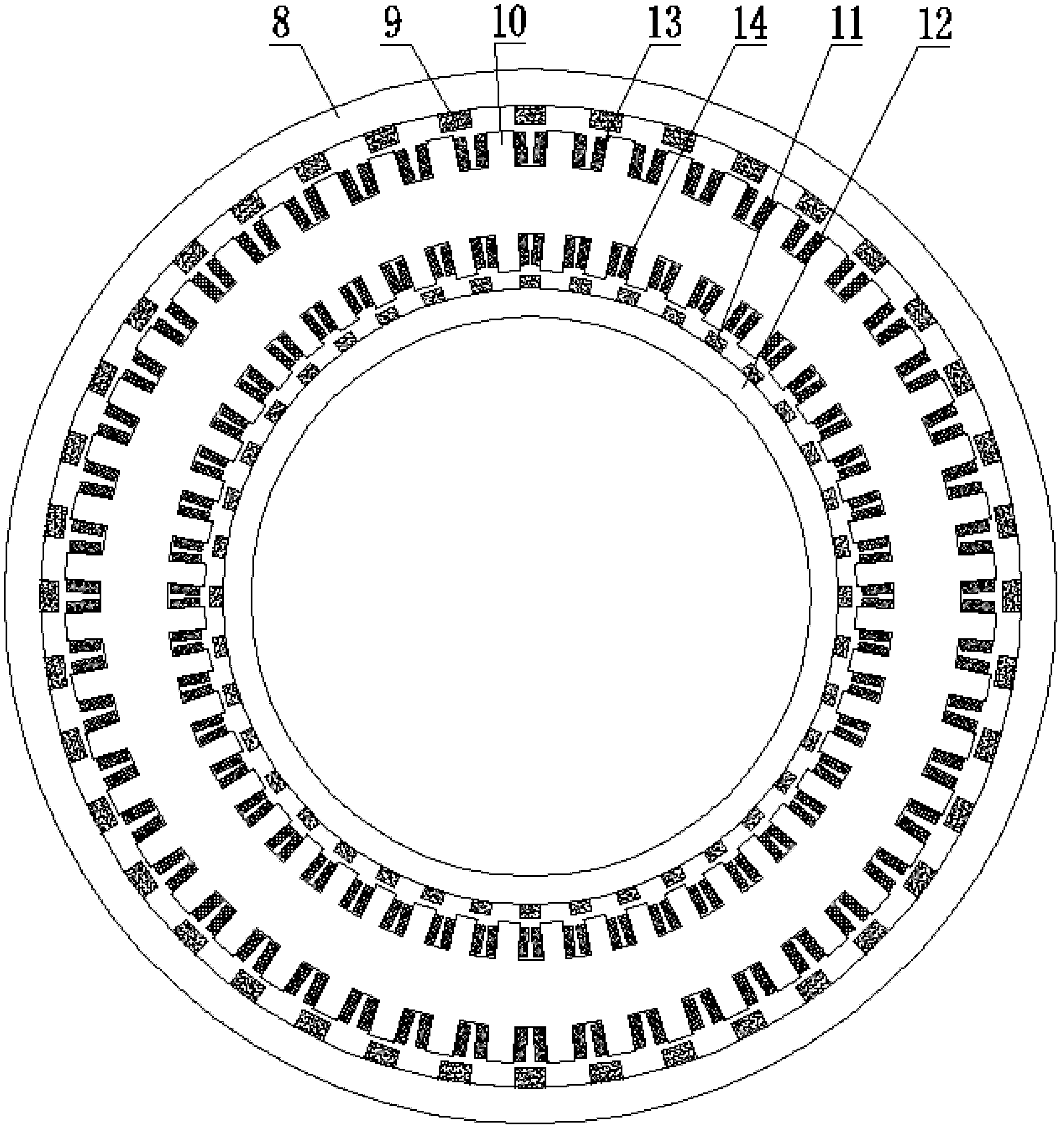

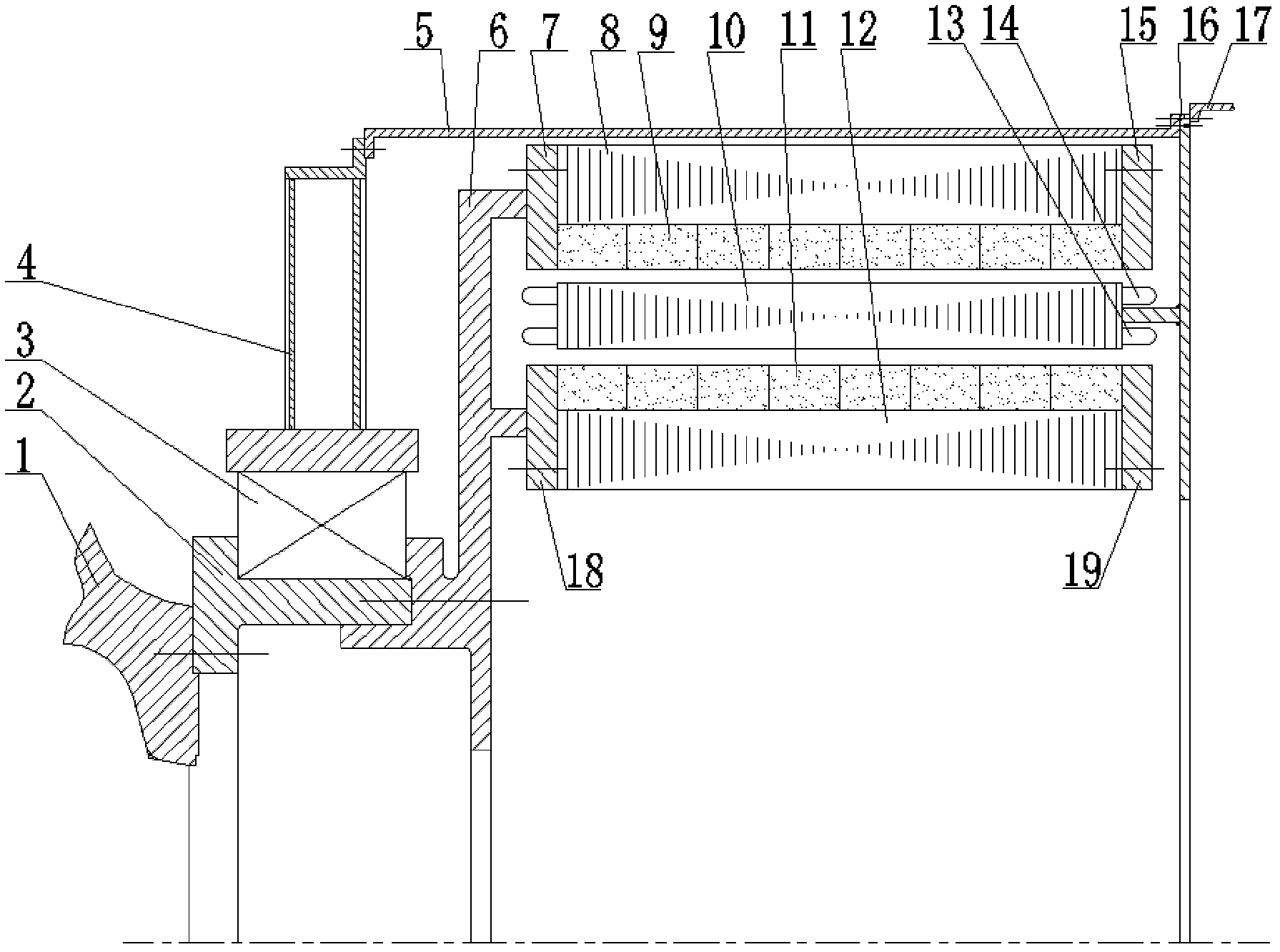

[0023] see figure 1 As shown, the large-scale dual-rotor direct-drive permanent magnet wind generator of the present invention adopts a dual-rotor structure composed of an outer rotor and an inner rotor, and the stator is located between the outer rotor and the inner rotor. The outer rotor and the stator form a first working air gap, the inner rotor and the stator form a second working air gap, and the magnetic circuits of the first working air gap and the second working air gap are connected in series.

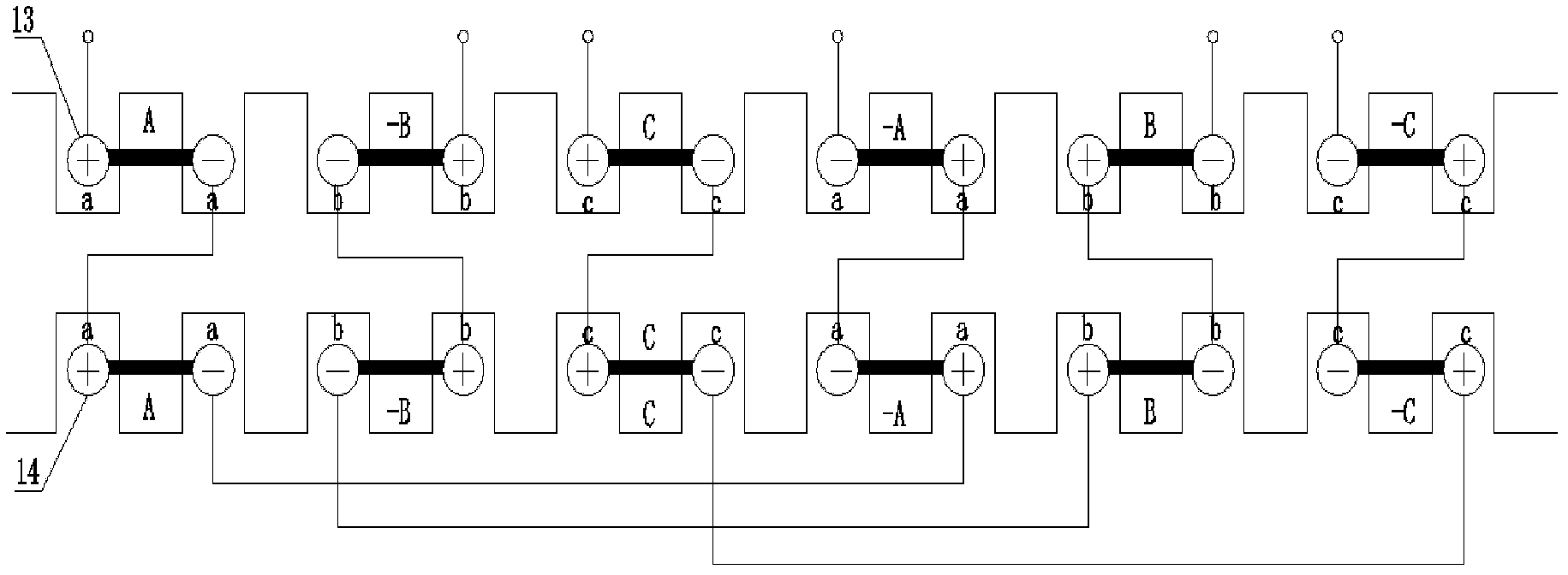

[0024] Among them, the stator is mainly composed of a stator core 10, an outer surrounding group 13 and an inner surrounding group 14, and both the inner and outer surrounding groups adopt the single-pitch centralized winding form of fractional slots.

[0025] Please refer to figure 2 As shown, the inner winding group 14 and the outer winding group 13 are connected in anti-phase to the corresponding windings of the same phase.

[0026] The outer rotor is composed of an out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com