High voltage excitation constant current power supply system

A power supply system and excitation technology, which is applied in the field of high-voltage excitation constant current power supply system, can solve the problems of poor tube performance, rise in temperature of the stabilizer, and large power consumption of the stabilizer, so as to reduce the volume and weight, and avoid power consumption. Loss, the effect of improving utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

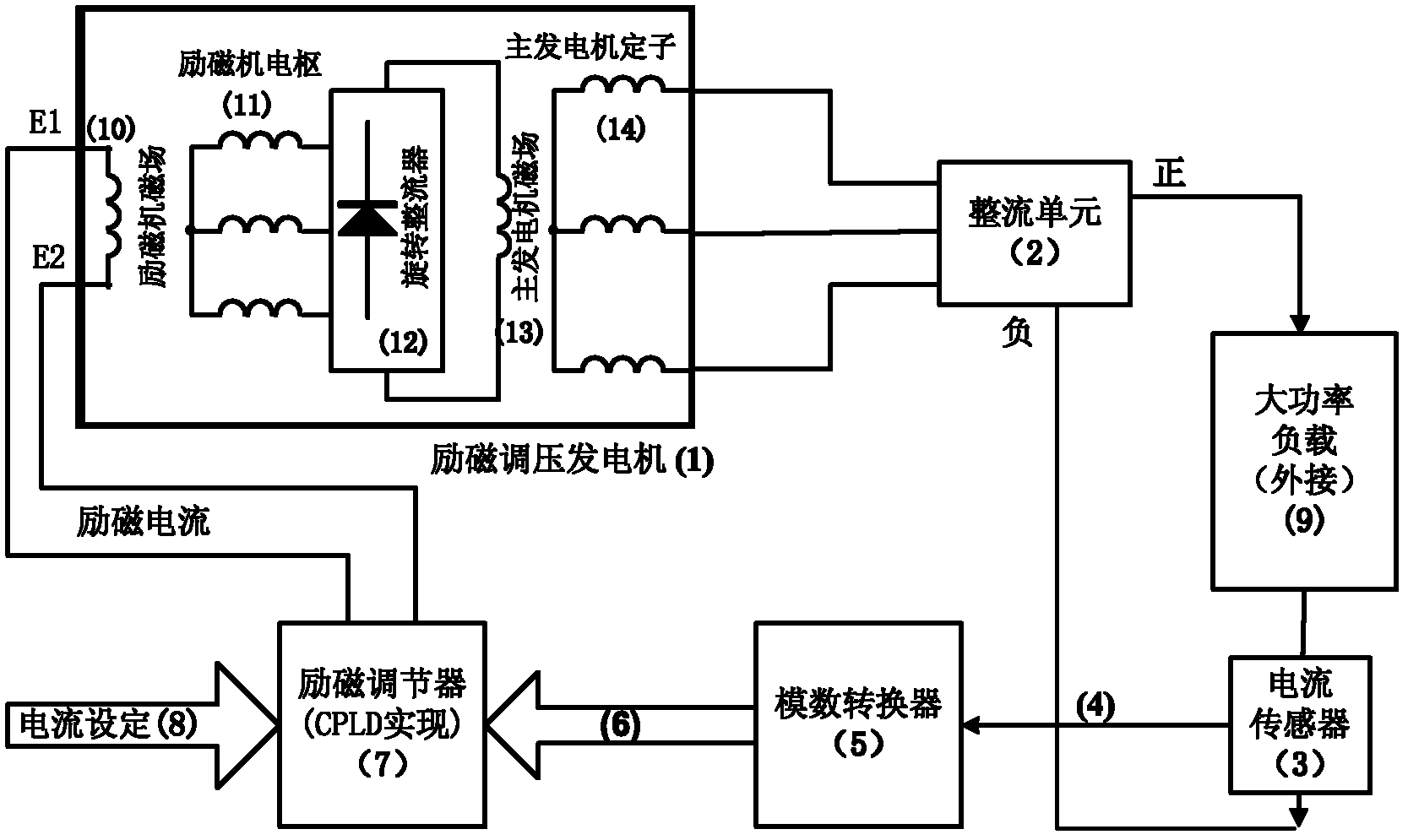

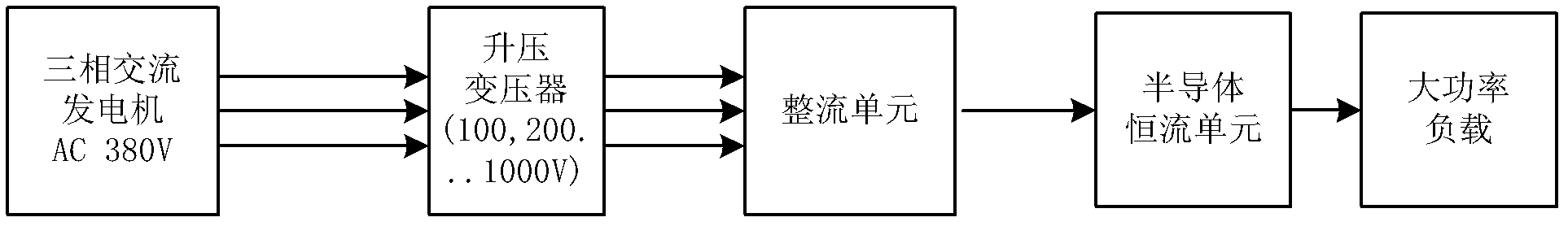

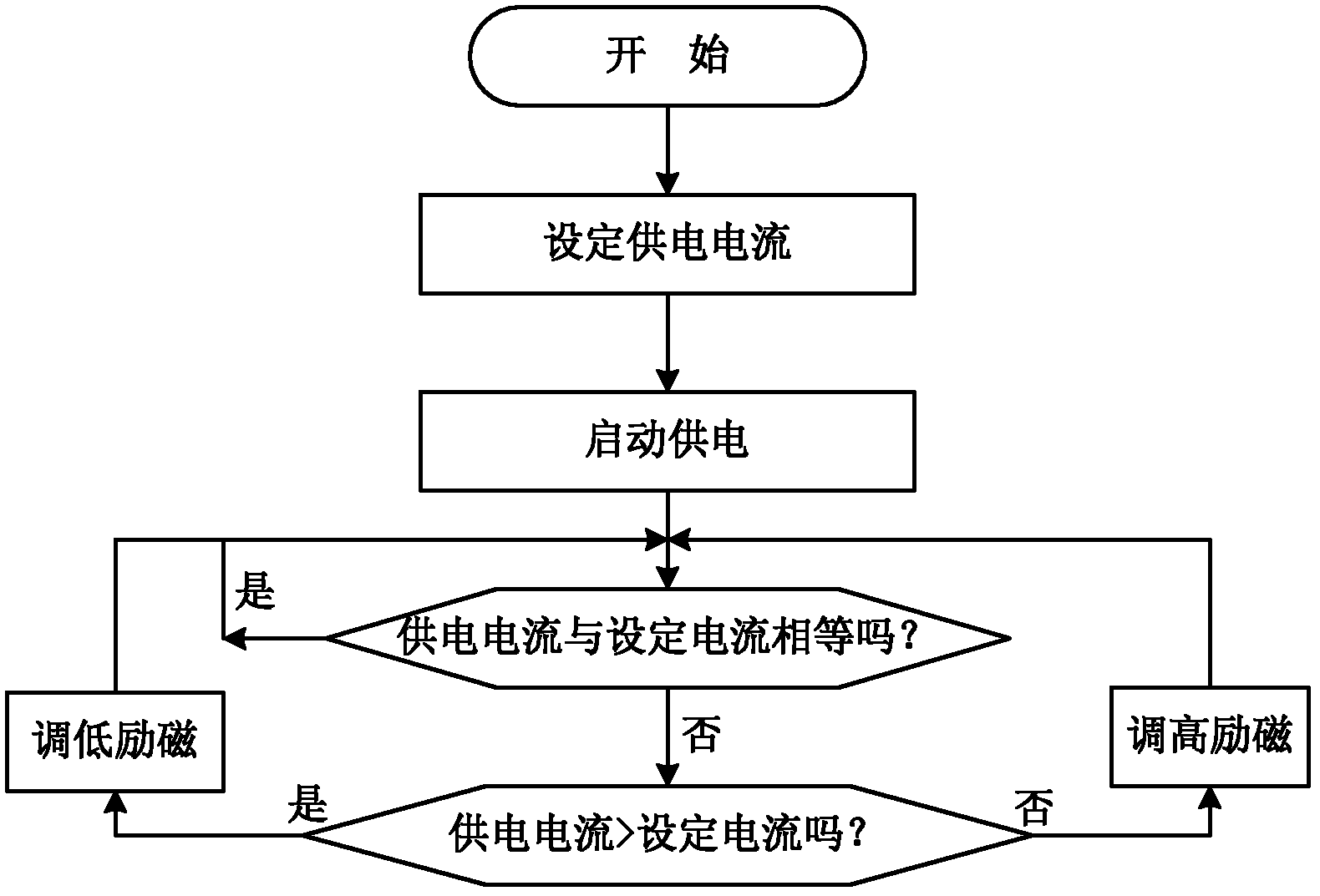

[0031] The invention relates to a high voltage excitation constant current power supply system. It uses an excitation voltage regulating generator and an excitation regulator to replace the generator, step-up transformer and semiconductor current stabilizing unit in the traditional technical solution. The excitation constant current power supply system adjusts the output voltage of the generator in real time according to the change of the power supply current, so that the power supply current remains constant, and realizes the constant current power supply based on the generator excitation adjustment.

[0032] Further description will be made below in conjunction with the accompanying drawings.

[0033] Please refer to the block diagram of the present invention figure 1 , including an excitation regulator generator 1 , a rectifier unit 2 , a current sensor 3 , an analog-to-digital converter 5 , an excitation regulator 7 and a high-power load 9 .

[0034] The output voltage ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com