High-power light emitting diode (LED) driving circuit

An LED driving, high-power technology, applied in the circuit layout of electric lamps, electric light sources, lighting devices, etc., can solve the problems of unstable switching oscillation, unstable output current, and inability to work, and achieve stable current, high stability, and cost. bottom effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with accompanying drawing. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

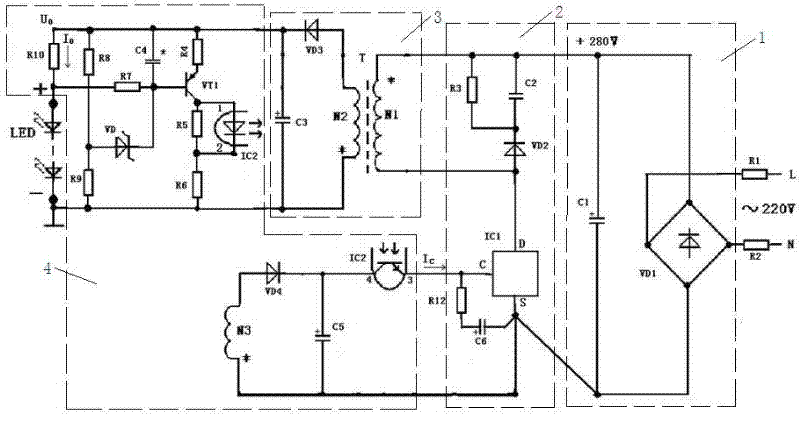

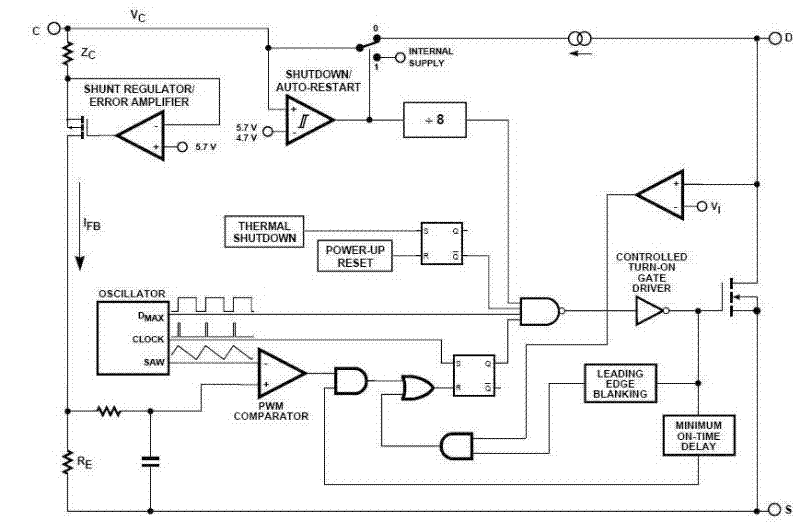

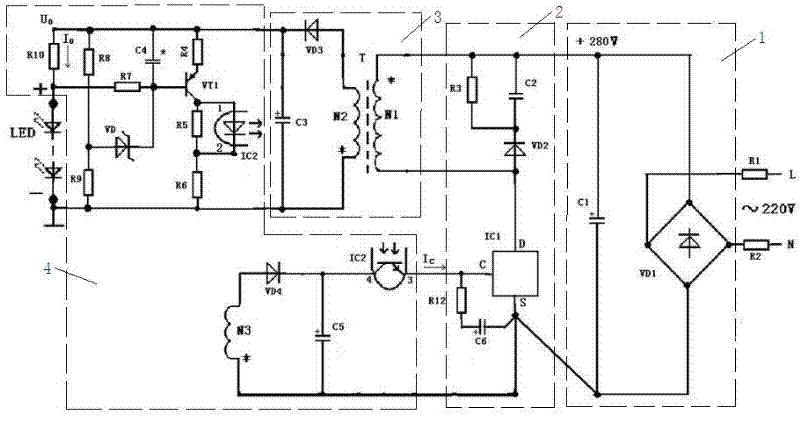

[0023] Such as figure 1 As shown, a high-power LED drive circuit is a typical single-ended flyback switching circuit, and the operating frequency has been internally set to 100KHZ. It includes a rectifier module 1 for rectifying the input AC power, a drive module 2 connected to the rectifier module 1 at one end, a transformer module 3 and a light source module 4 respectively connected to the other two ends of the drive module 2 . The driving module 4 includes a monolithic integrated switch circuit IC1. In this embodiment, the monolithic integrated switch circuit IC1 selects a triode whose model is TOP224Y. The AC 220V voltage is input, and the drive module 2 outputs a switching constant current cir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com