Ballpoint pen ink and ballpoint pens using the ink

A ballpoint pen and ink technology, applied in the direction of ballpoint pen, ink, pen tip, etc., can solve the problems of easy movement of ink film, lack of smooth writing feeling, low fluidity of ink, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

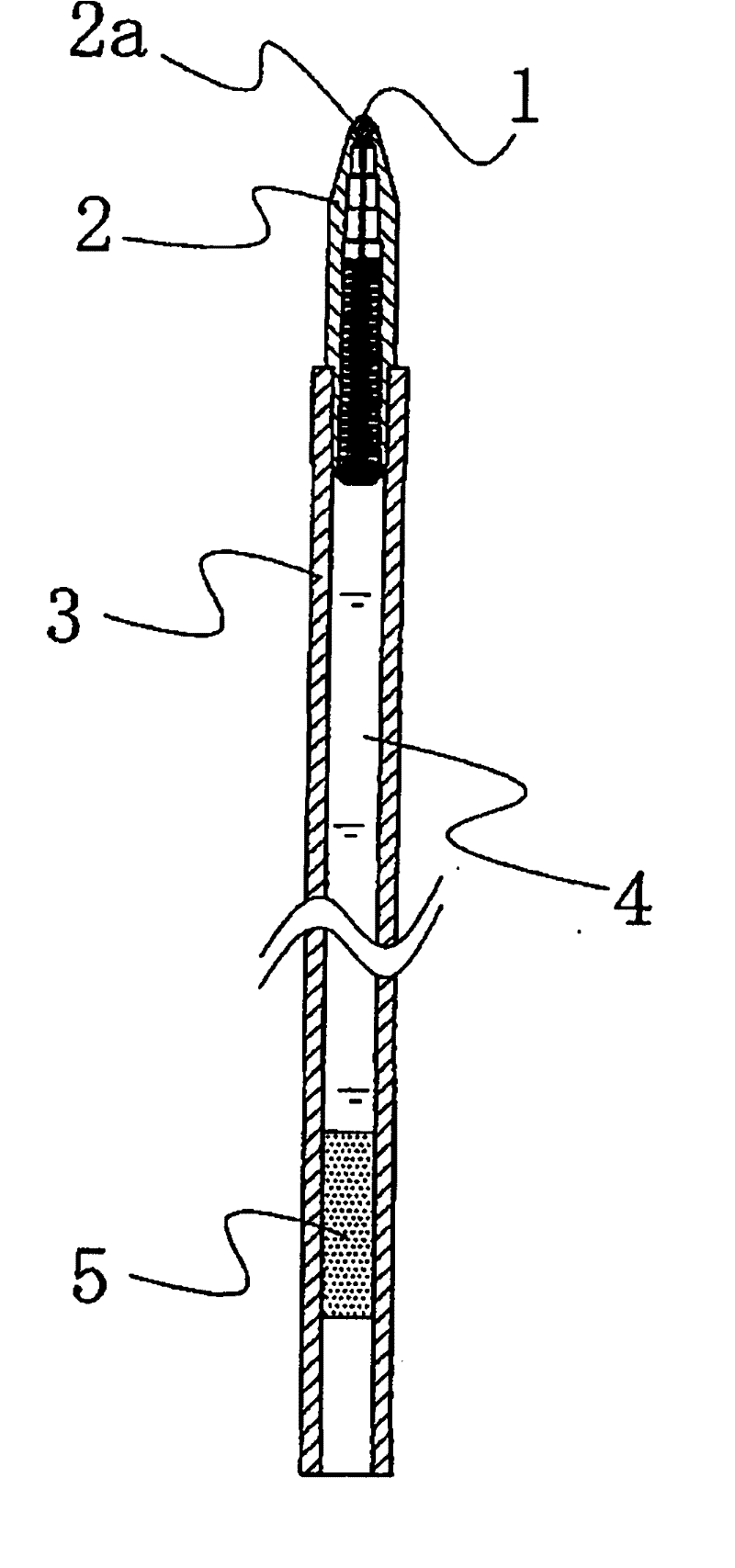

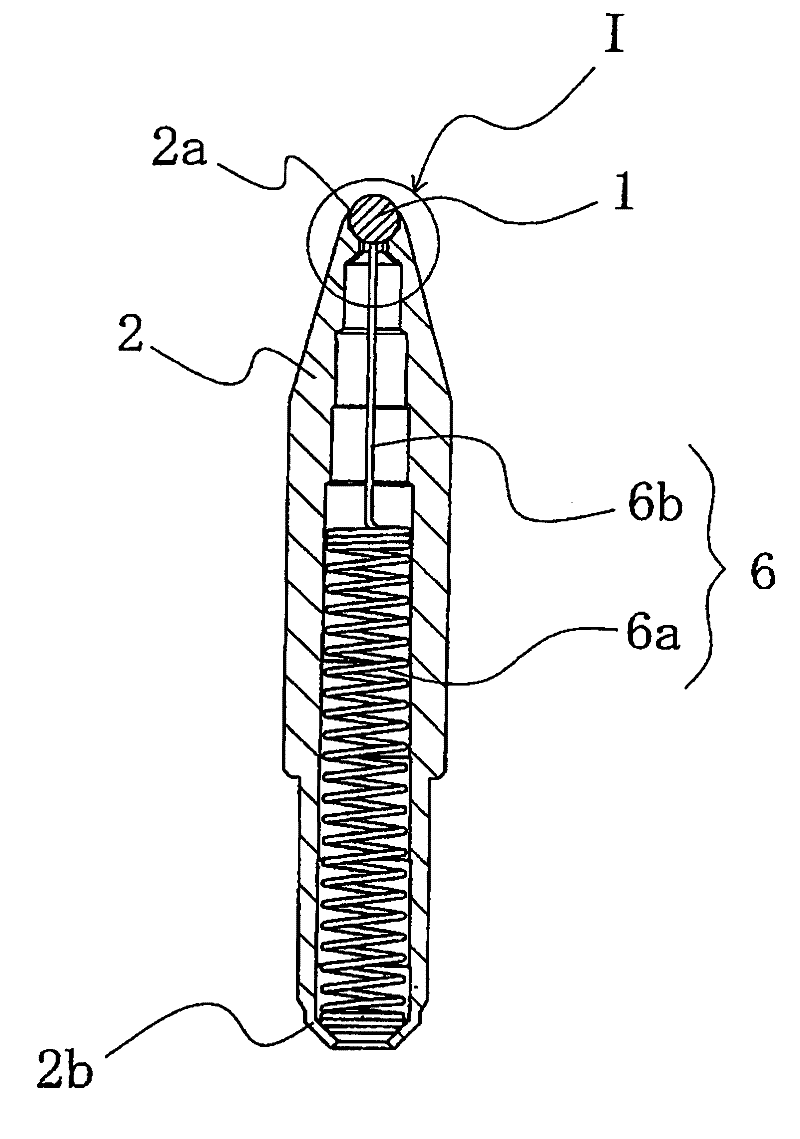

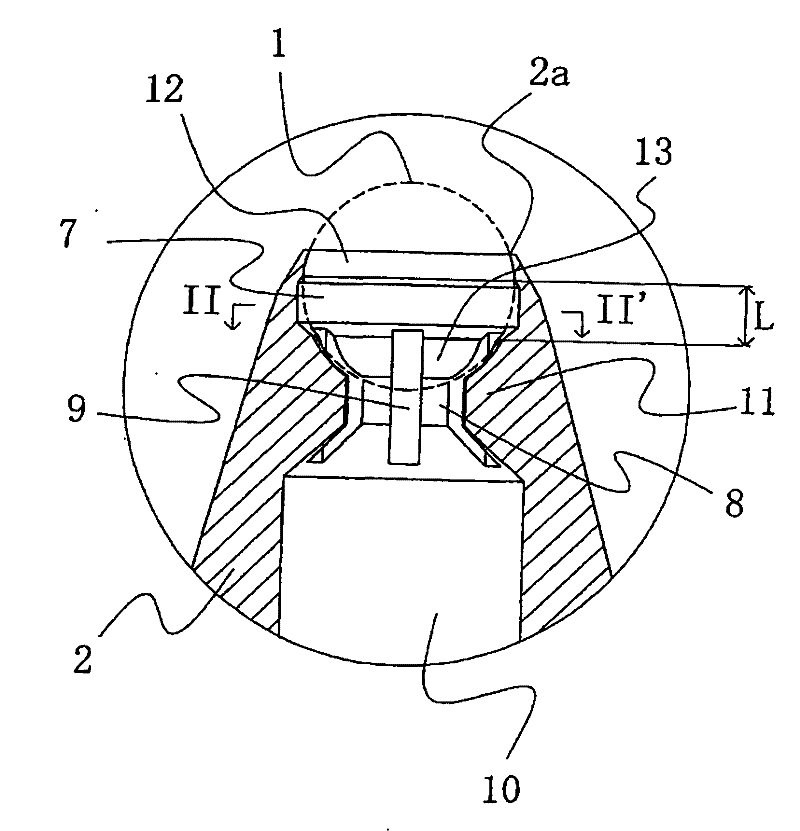

Image

Examples

Embodiment

[0126] Examples of actual preparation and evaluation of ballpoint pens according to the present invention will be described below. The following inks A to W were prepared. Incidentally, in each ink, when "part" is simply used, it means "part by weight". Inks A to Q are subject inks of the present invention, and inks R to W are not subject inks of the present invention.

[0127] (ink A)

[0128]

[0129]

[0130] Of the above ingredients, the entire amount of diethylene glycol monomethyl ether, the amount of ethylene glycol monoisopropyl ether, and the entire amount of S-LEC BL-1 were stirred, mixed and dissolved at 70°C, and the resulting solution was cooled to room temperature. The entire amount of Printex 35 was added thereto, and the mixture was subjected to 10 passes through Kyno-Mill (bead mill, manufactured by Shinmaru Enterprises Co., Ltd.) using zirconia beads with a diameter of 0.3 mm to obtain a black slurry.

[0131]Each remaining material was added to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com