Okra tea and its production process

A kind of okra and drying technology, which is applied in the direction of tea substitutes, etc., can solve the problems of not improving the utilization value, and achieve the effects of being convenient to carry and eat, increasing the added value of utilization, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

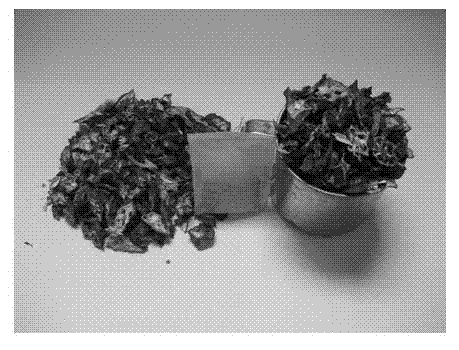

Image

Examples

Embodiment 1

[0016] A production process of okra tea, which mainly includes the following steps: (1) picking: picking okra with a length of 10-15 cm; (2) picking and picking: picking picky okra according to size, tenderness, and color; ( 3) Refrigeration in storage: Refrigerate the picked okra fruit at 0°C for 10 hours; (4) Slicing: Cut vertically along the length of the fruit into thin slices with a thickness of 2 cm; (5) Drying: Cut the sliced okra fruit Carry out deenzyming and drying in the dryer, the decapitation temperature is 101°C, and the time is <30 minutes; the drying temperature is: 70°C, until the moisture content is 6-8%; (6) Sterilization: the dried okra fruit Sterilize to get okra tea; (7) Packing: pack the sterilized okra tea.

Embodiment 2

[0018] A production process of okra tea, which mainly includes the following steps: (1) picking: picking okra with a length of 10-15 cm; (2) picking and picking: picking picky okra according to size, tenderness, and color; ( 3) Refrigeration in storage: Refrigerate the picky okra fruit at 10°C for 14 hours; (4) Slicing: Cut vertically along the length of the fruit into thin slices with a thickness of 4 cm; (5) Drying: Cut the sliced okra The fruit is sterilized and dried in the dryer. The temperature for sterilizing is 90°C and the time is less than 30 minutes; the drying temperature is 50°C until it is dried; (6) Sterilization: sterilize the dried okra tea fruit , to obtain the okra tea; (7) Packing: packing the sterilized okra tea.

Embodiment 3

[0020] A production process of okra tea, which mainly includes the following steps: (1) picking: picking okra with a length of 10-15 cm; (2) picking and picking: picking okra according to size, tenderness and color; ( 3) Refrigeration in storage: Refrigerate the picky okra fruit at 5°C for 12 hours; (4) Slicing: Cut vertically along the length of the fruit into thin slices with a thickness of 3 cm; (5) Drying: Put the sliced okra fruit in the Carry out de-enzyming and drying in the dryer, the de-enzyming temperature is 90-110°C, and the time is less than 30 minutes; the drying temperature is: 60°C, until it is dried; (6) Sterilization: Sterilize the dried okra tea fruit , to obtain the okra tea; (7) Packing: packing the sterilized okra tea.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com