Automatic Rectangular Rubber Ring Cutting Machine

A rubber ring and cutting machine technology, applied in metal processing, etc., can solve problems such as long production cycle, increased product scrap rate, and increased requirements for operators, and achieve the effects of high automation, improved safety, and simple operation methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

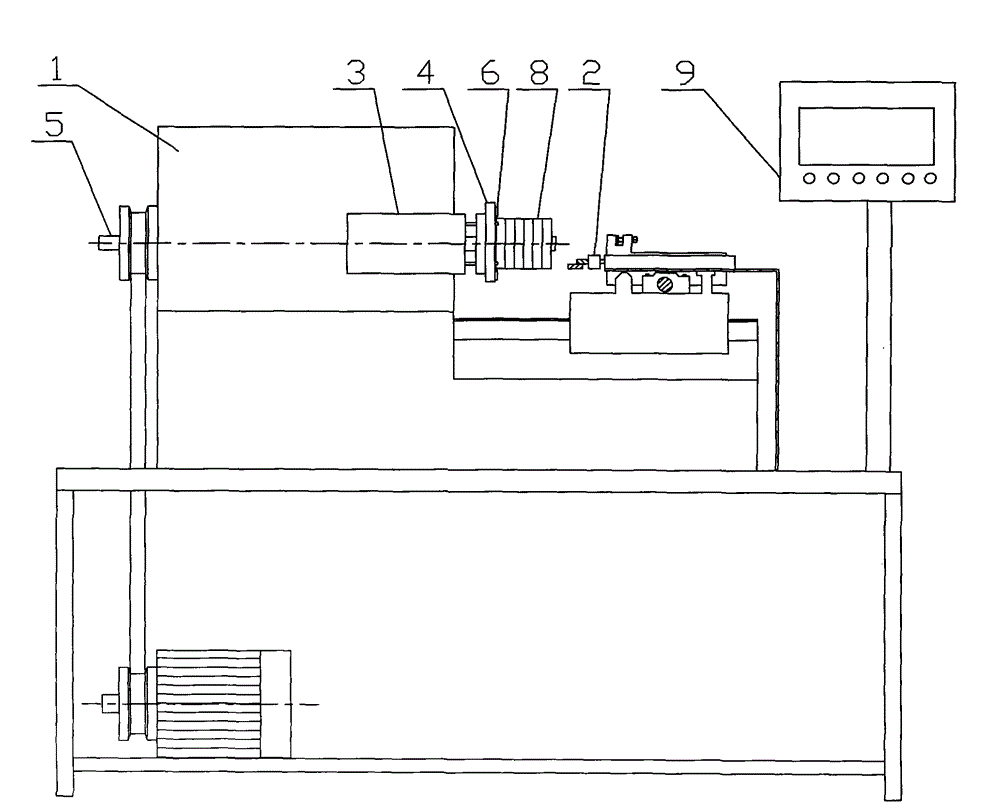

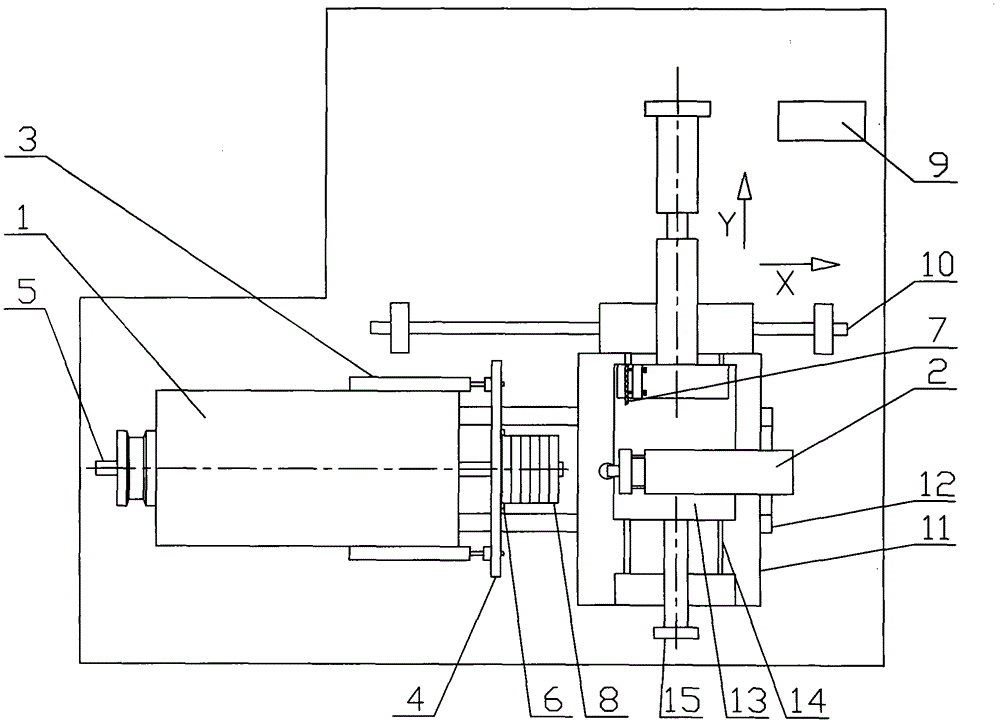

[0015] Such as Figure 1~2 In the shown embodiment, the automatic rectangular rubber ring cutting machine of the present invention includes a machine base and a cutting device connected to a PLC control system 9, one end of the machine base is provided with an axle box 1 connected to a motor, and the other end of the machine base is provided with Feeding device 2, feeding device 2 includes a bracket and a feeding mechanism arranged on the bracket and controlled by a feeding cylinder, two axle box cylinders 3 are arranged symmetrically on both sides of the axle box 1, and the axle box cylinder 3 is connected with a push plate 4. The rotating shaft 5 provided by the axle box 1 passes through the push plate 4, and the workpiece limit device 6 is arranged on the push plate 4. The cutting device includes an X-axis guide device, a Y-axis guide device arranged on the X-axis guide device and The knife rest and cutter 7 arranged on the Y-axis guide.

[0016] When feeding, the product ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com