Prepreg Compression Molding Method

A prepreg and preforming technology, which is applied in the field of materials, can solve the problems of easy deformation of products and poor bonding strength between product layers, and achieve the effects of improving bonding strength, overcoming insufficient positive pressure, and not easily deforming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

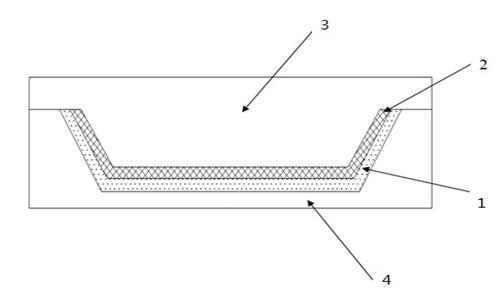

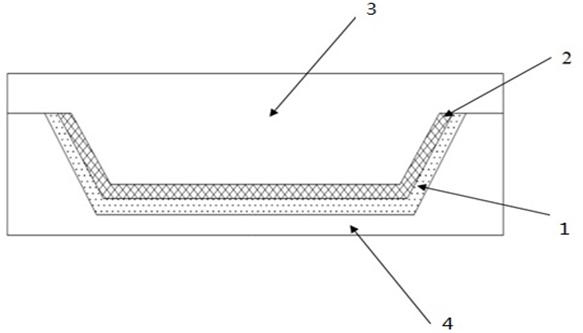

Image

Examples

Embodiment 1

[0018] The prepreg molding thermoforming of this embodiment comprises the following steps:

[0019] (1) Prepreg layering; take phenolic molding material, punch the prepreg into required specifications with a knife die, and lay up the material;

[0020] (2) Prepreg preforming, laying up and preforming phenolic molded material sheets according to conventional methods;

[0021] (3) Curing and molding; the curing and molding is: punching the silicone sheet into the required shape with a knife mold;

[0022] Coat oleic acid in the lower mold of the mold, then paste the silicone sheet, and then put the preformed prepreg on the silicone sheet;

[0023] Heating after closing the mold, first heating up, the heating rate is 10°C per hour, keeping warm for 2 minutes when the temperature rises to 160°C, and then cooling down; at the same time, pressurizing 20 minutes after closing the mold, the pressure is 10MPa; heating will make the silicone sheet When heated, it expands to generate i...

Embodiment 2

[0026] The prepreg molding thermoforming of this embodiment comprises the following steps:

[0027] (1) Prepreg layering; take phenolic molding material, punch the prepreg into required specifications with a knife die, and lay up the material;

[0028] (2) Prepreg preforming, laying up and preforming phenolic molded material sheets according to conventional methods;

[0029] (3) Curing and molding; the curing and molding is: punching the silicone sheet into the required shape with a knife mold;

[0030] Coat paraffin wax in the lower mold of the mold, then paste the silicone sheet, and then put the preformed prepreg on the silicone sheet;

[0031] Heating after closing the mold, first heating up, the heating rate is 25 ° C per hour, when the temperature rises to 170 ° C, keep warm for 3 minutes, and then cool down; at the same time, pressurize 30 minutes after closing the mold, the pressure is 29 MPa; heating will make the silicone sheet When heated, it expands to generate i...

Embodiment 3

[0034] The prepreg molding thermoforming of this embodiment comprises the following steps:

[0035] (1) Prepreg layering; take phenolic molding material, punch the prepreg into required specifications with a knife die, and lay up the material;

[0036] (2) Prepreg preforming, laying up and preforming phenolic molded material sheets according to conventional methods;

[0037] (3) Curing and molding; the curing and molding is: punching the silicone sheet into the required shape with a knife mold;

[0038] Coat silicone rubber in the lower mold of the mold, then paste the silicone sheet, and then place the preformed prepreg on the silicone sheet;

[0039] After closing the mold, heat it up, firstly heat up at a rate of 30°C per hour, keep warm for 5 minutes when the temperature rises to 175°C, and then cool down; at the same time, pressurize 90 minutes after closing the mold, the pressure is 39MPa; heating will make the silicone sheet When heated, it expands to generate interna...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com