A pile foundation quality detection method and device thereof

A quality inspection method and pile foundation technology, which can be applied in basic structure engineering, basic structure testing, construction, etc., can solve the problems of affecting the reliability of test results, high cost, weak reflected signal, etc., and achieve high-precision pile foundation without loss of quality. Effectiveness of detection and reliability improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

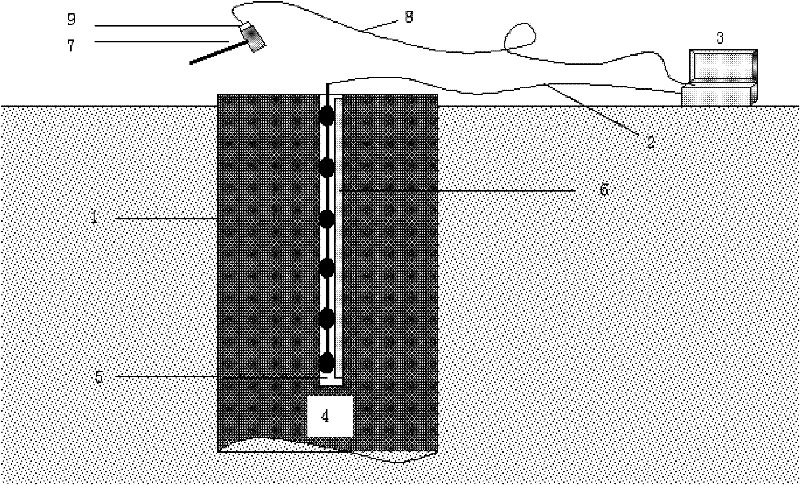

[0021] see figure 1 , the device for realizing the pile foundation quality detection method, the detector string 1 formed by 4 to 16 miniature speed or acceleration sensors with an interval of 5 to 15 cm, the output signal of the detector string 1 passes through the first signal cable 2 and multiple channels The synchronous elastic wave acquisition instrument 3 is connected, and the trigger 9 carried by the hammering source 7 is connected with the multi-channel synchronous elastic wave acquisition instrument 3 through the second signal cable 8; A wall-attaching device in which the wave detector is closely attached to the wall of the detection hole 5 . Adhesive device is machinery, magnetoelectric type or air bag 6, water bag.

[0022] The pile foundation quality inspection method comprises a plurality of miniature speed or acceleration sensor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com