A wet orifice eddy current collection and control device and method

A vortex and orifice technology, which is applied in the field of wet orifice vortex collection and dust control devices, can solve problems such as endangering the physical and mental health of coal mine safety production workers, dust escaping, and extremely serious dust pollution in drilling operations, and achieves a simple structure , good effect, easy to assemble

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

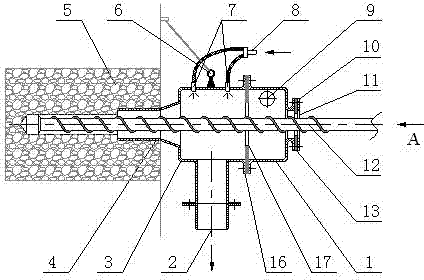

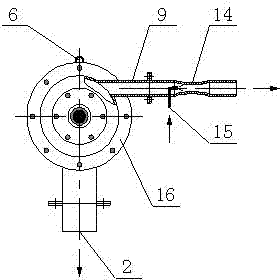

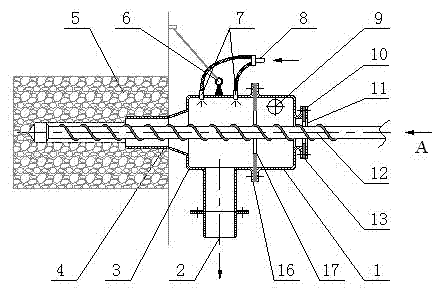

[0015] An embodiment of the present invention is further described below in conjunction with accompanying drawing:

[0016] The wet orifice eddy current dust collection and control device of the present invention comprises two parts, the dust collector front cover 1 and the dust collector rear cover 3, and the dust collector front cover 1 and the dust collector rear cover 3 are connected by a detachable flange 16. connection, with an annular partition 17 separating it into two areas in the middle. The front cover 1 of the dust collector is provided with a vortex dust discharge pipe 9, and a Venturi jet ejector 14 is installed on the vortex dust discharge pipe 9, and a high-pressure water nozzle 15 is installed inside the Venturi jet ejector 14. A drill pipe inlet 11 is provided on the end face of the cover 1, and a flame-retardant and wear-resistant collar 13 that can penetrate into the drill pipe 12 is installed and fixed on the drill pipe inlet 11 through a fixed flange 10; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com