An optical engine with variable field of view

An optical engine and engine technology, applied in the direction of engine components, machines/engines, mechanical equipment, etc., can solve problems such as inability to meet multiple measurement requirements at the same time, and achieve the effect of high mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

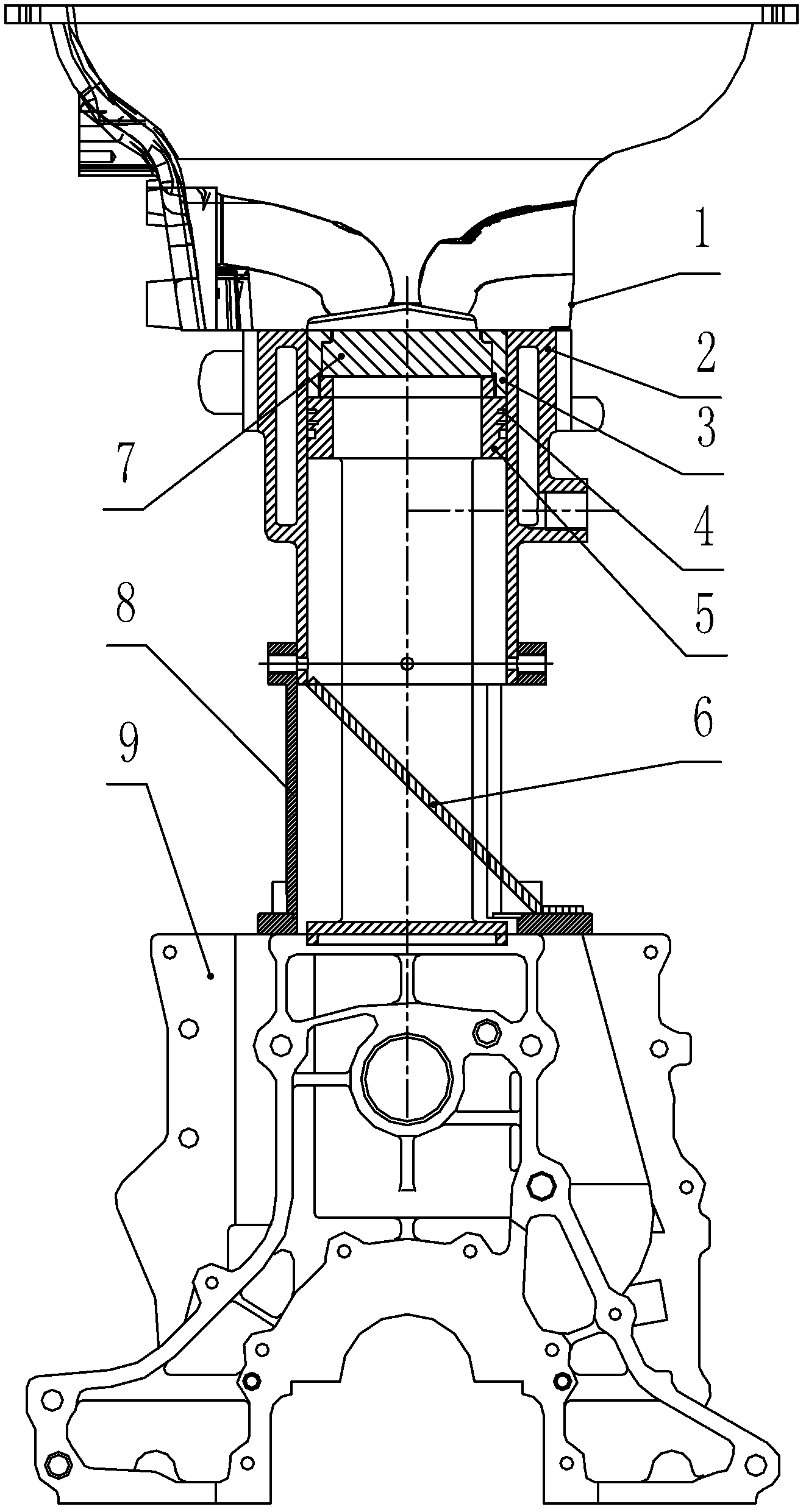

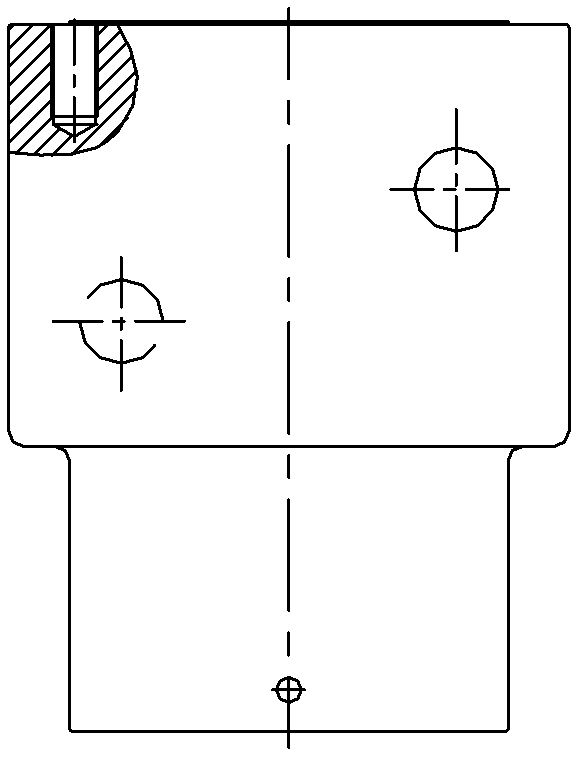

[0046] The piston of a certain cylinder of the prototype machine is threadedly connected with the extended piston 5, and the top of the extended piston 5 is provided with a glass groove for placing a circular flat quartz glass 7. Glass 7 is fixed on the top of extension piston 5. At the same time, the length of the extended piston is controlled to ensure the compression ratio of the engine. Have piston ring groove 4 on the extension piston 5, be used for installing gas ring and lubricating graphite ring, gas ring can guarantee the tightness of engine, and the installation of graphite ring guarantees the lubrication of lengthening piston and cylinder liner.

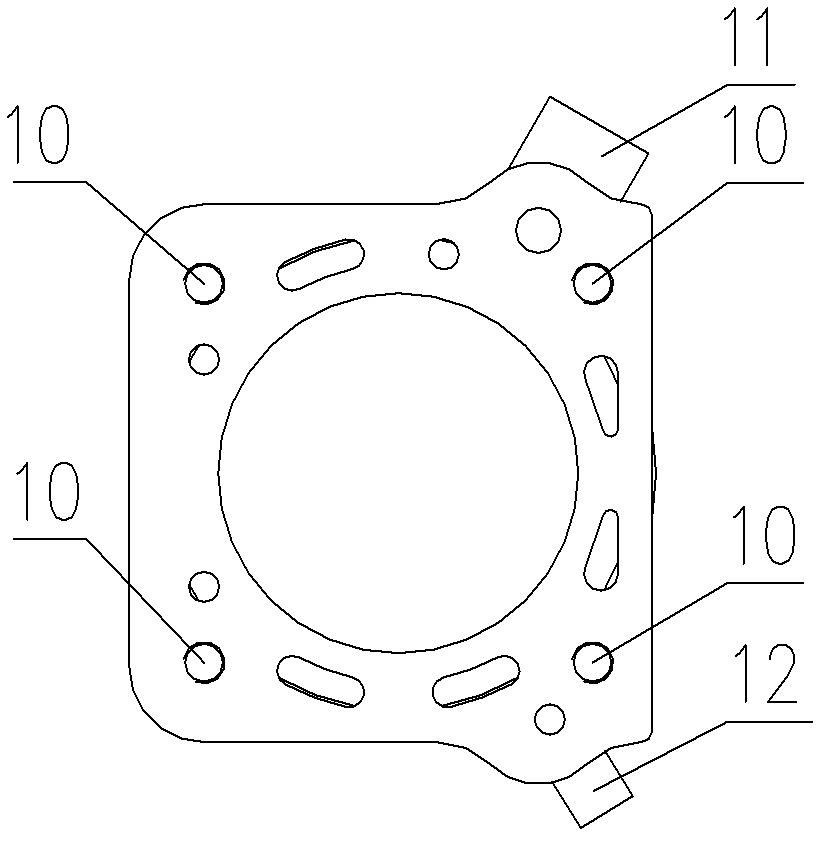

[0047] The outer sleeve of the extended piston is provided with a metal lengthened cylinder liner 2, and there are 4 threaded holes 10 on the metal lengthened cylinder liner 2, such as Figure 1-2 As shown, the metal extended cylinder liner 2 and the cylinder head 1 are connected by four cylinder head bolts, and the metal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com