Method and device for decoupling and burning solid waste with high water content

A solid waste and combustion device technology, which is applied in the direction of combustion method, combustion type, lighting and heating equipment, etc., can solve the problem of unsatisfactory drying effect of flue gas, and achieve overcoming ignition difficulties, wide adaptability, and strong application and promotion Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

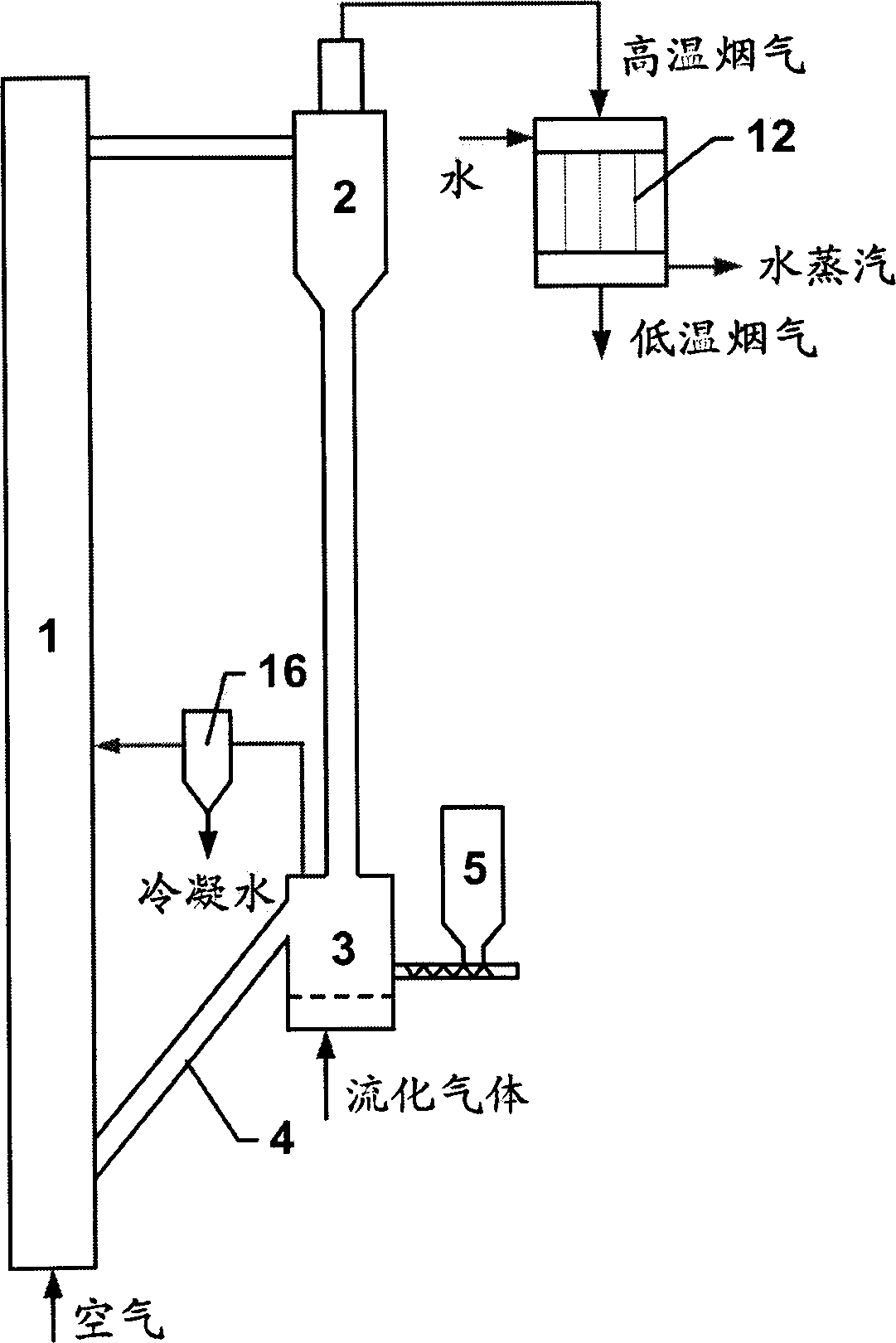

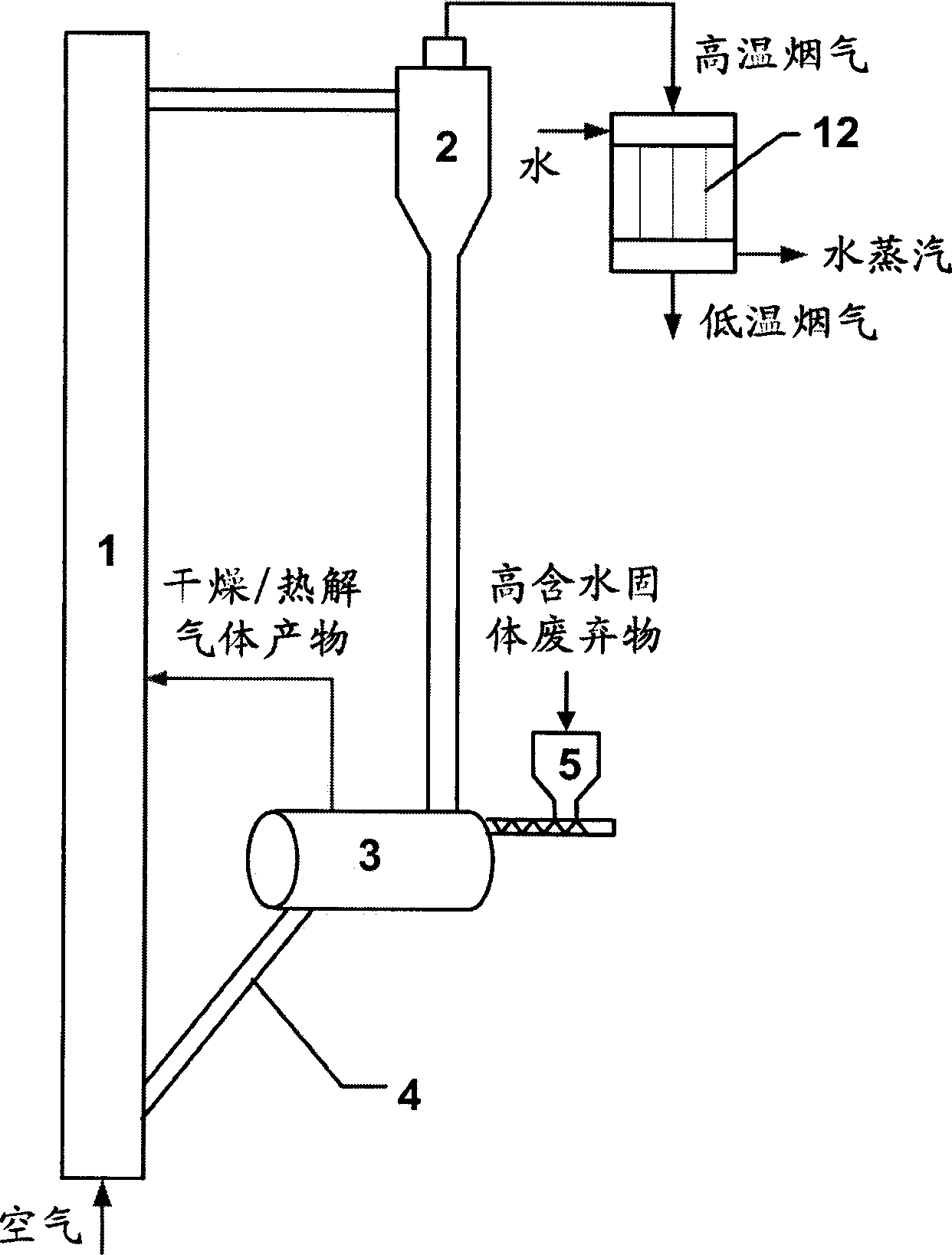

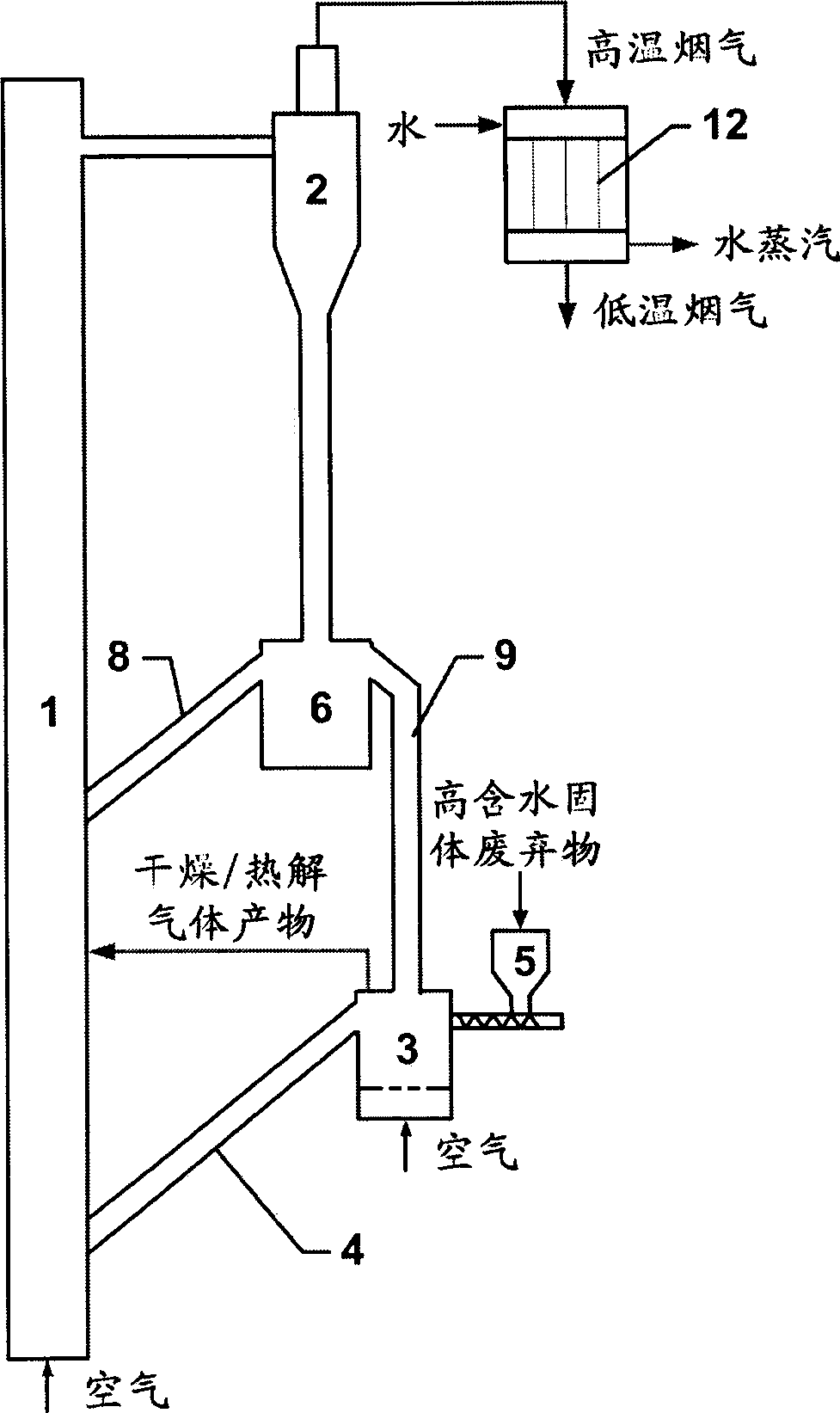

[0044] Such as figure 1 Or 2 shown in embodiment 1 and embodiment 2 adopt solid heat carrier to simultaneously dry and pyrolyze high water content solid waste in a reactor, burn the decoupled combustion of high water content solid waste distiller's grains completed in the burner method, including the following steps:

[0045] (a) sending high-water solid waste with a water content of 10 to 65% into the dry pyrolysis device 3, and performing dry pyrolysis in the presence of a heat carrier;

[0046] (b) The pyrolysis gas component coming out from the dry pyrolyzer 3 enters the middle part of the burner 1, partially burns, and partially reduces the nitrogen oxides produced by the combustion to reduce the emission of nitrogen oxides;

[0047] (c) the solid mixture produced in the dry pyrolyzer 3 enters the burner 1 for combustion, and the heat generated is transferred to the solid heat carrier;

[0048] (d) The solid heat carrier is discharged from the upper end of the burner 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com