Device and method for detecting reference spherical wave deviation in visible light point diffraction interferometer

A point-diffraction interferometer and reference sphere technology, used in measuring devices, optical radiation measurement, instruments, etc., can solve problems such as limited accuracy and inability to meet detection requirements, and achieve the effect of high-precision detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

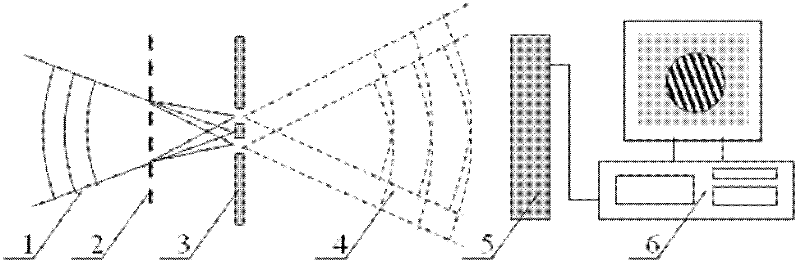

[0024] Such as figure 1 As shown, the reference spherical wave deviation detection device in the visible light point diffraction interferometer of the present invention includes: a grating 2, a small hole plate 3 with three circular holes along the orthogonal direction, a CCD detector 5, a computer 6, The small hole plate 3 is located between the grating 2 and the CCD detector 5; the grating 2 diffracts the converging light wave 1 passing through it, and the diffracted light is diffracted by the small hole plate 3 and interferes and superimposed, and is detected by the CCD The interferogram is recorded on the detector 5; the computer 6 collects the recorded interferogram from the CCD detector 5 through the signal line.

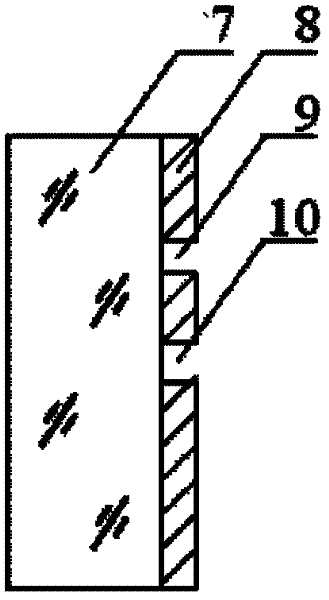

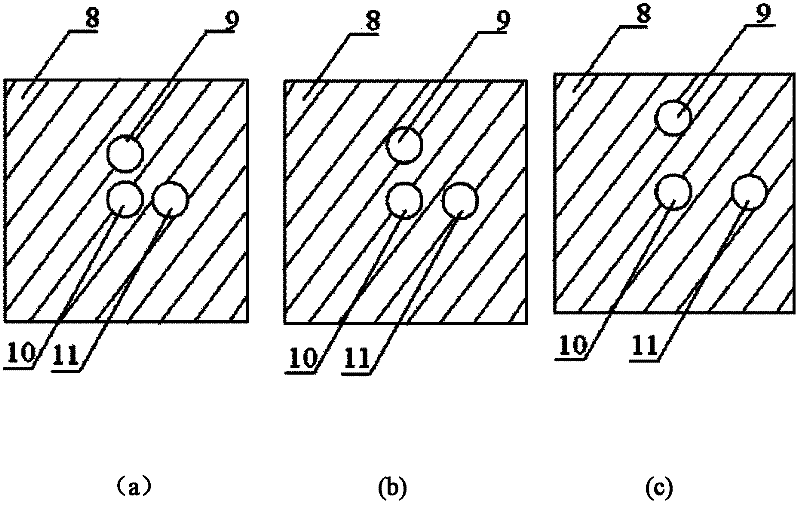

[0025] Such as figure 2 , image 3 As shown, glass substrate 7, metal chromium (Cr) layer 8, three round holes: hole one 10, hole two 9 and hole three 11, hole one 10 is located in the center of the small orifice plate, hole two 9 is located at the center o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com