Energy-saving optimization method of ball mill pulverization system in thermal power plant based on sequential pattern mining

A sequential pattern mining, thermal power plant technology, applied in general control systems, control/regulation systems, adaptive control, etc., can solve problems such as difficult application and complex algorithms

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] Below in conjunction with embodiment the present invention is described in more detail.

[0052] The energy-saving optimization method of ball mill pulverization system in thermal power plant based on sequential pattern mining, the steps are as follows:

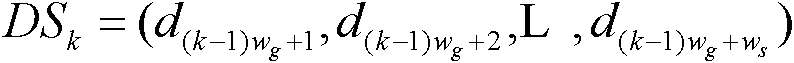

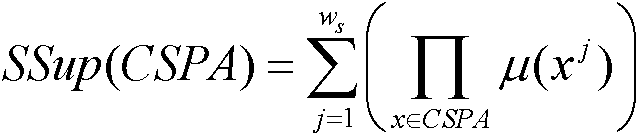

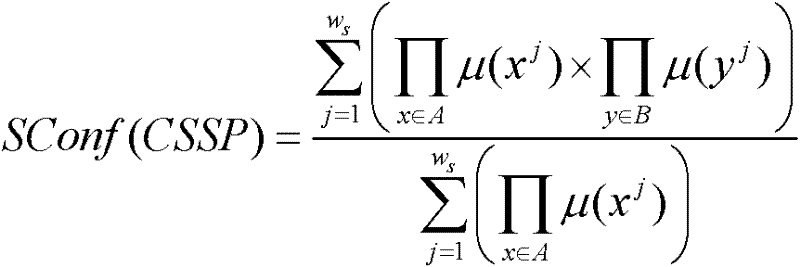

[0053] Step 1: First, the ball mill pulverization system of the thermal power plant invokes the sequential pattern mining generation module to construct the sequential pattern mining database D, and then the ball mill pulverization system of the thermal power plant passes The expression converts the value of the variable storage unit in the on-site historical database in its memory, and after conversion, the mill load l, mill outlet temperature ot, mill inlet negative pressure inp, Hot air door opening u h , at the opening degree of the recirculation damper u r , mill output pc, mill load setting value l sv , Mill outlet temperature setting value ot sv and mill inlet negative pressure setting inp sv According to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com