Cold-pressed terminal

A technology of cold-pressed terminals and free ends, which is applied in the direction of multi-core cable end parts, connections where permanent deformation works, etc., can solve the problems of inconvenient operation and the difficulty of cold-pressed terminals to meet the requirements of compact structure, and achieves space-saving, easy-to-use Installation and maintenance, effect of short radial length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

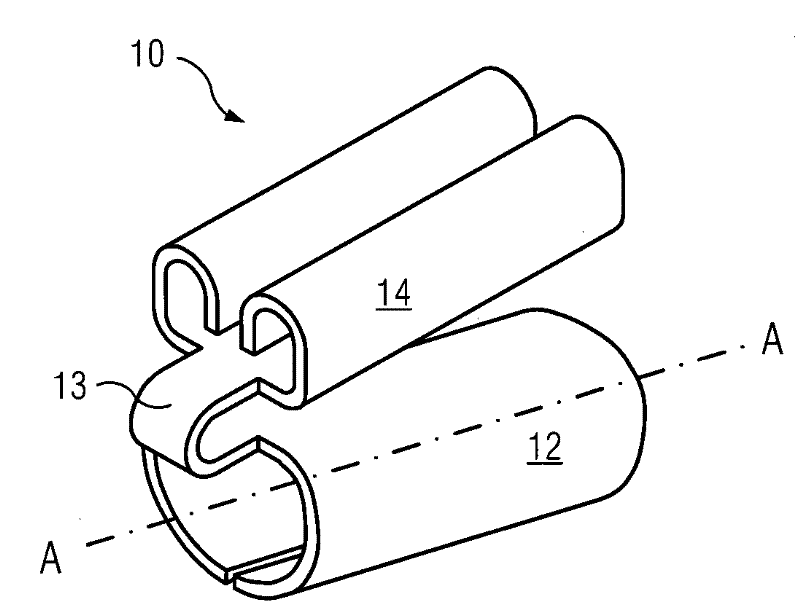

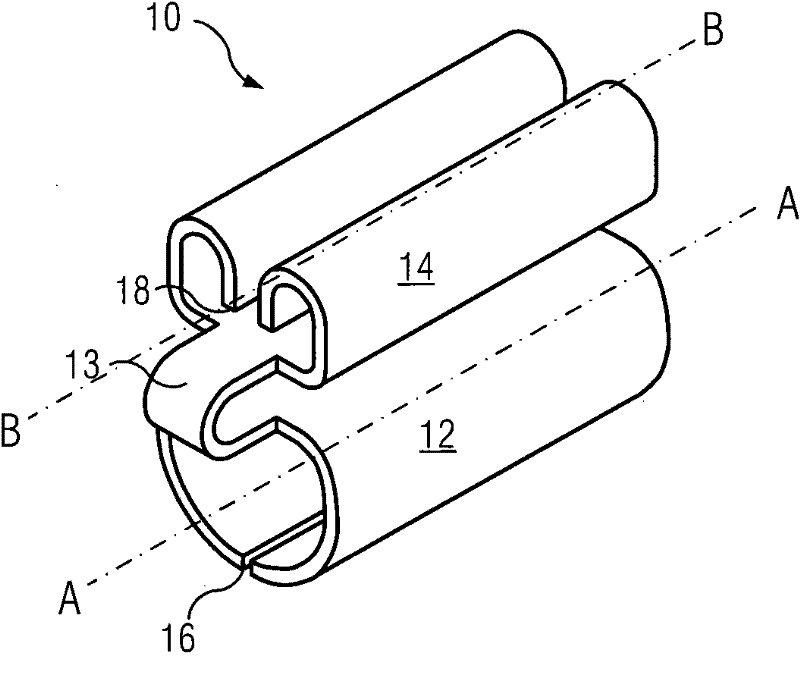

[0028] In order to have a clearer understanding of the technical features, purposes and effects of the invention, the specific implementation manners of the present invention will now be described with reference to the accompanying drawings, in which the same reference numerals represent the same parts.

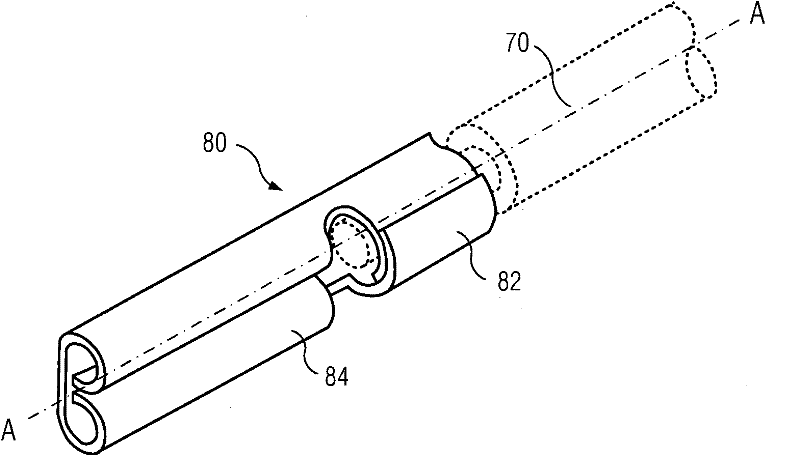

[0029] figure 2 One embodiment of the ferrule terminal 10 of the present invention is described. As shown in the figure, the ferrule terminal 10 includes a cable fitting part 12 and a connector fitting part 14 . The cable fitting portion 12 has an axis AA indicating a cable insertion direction, and the connector fitting portion 14 is superimposed on the cable fitting portion 12 in a direction perpendicular to the axial direction AA. The included angle between the above-mentioned connector fitting part 14 and the cable fitting part 12 can be determined within a range of less than 90 degrees according to actual manufacturing requirements and installation requirements.

[003...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com