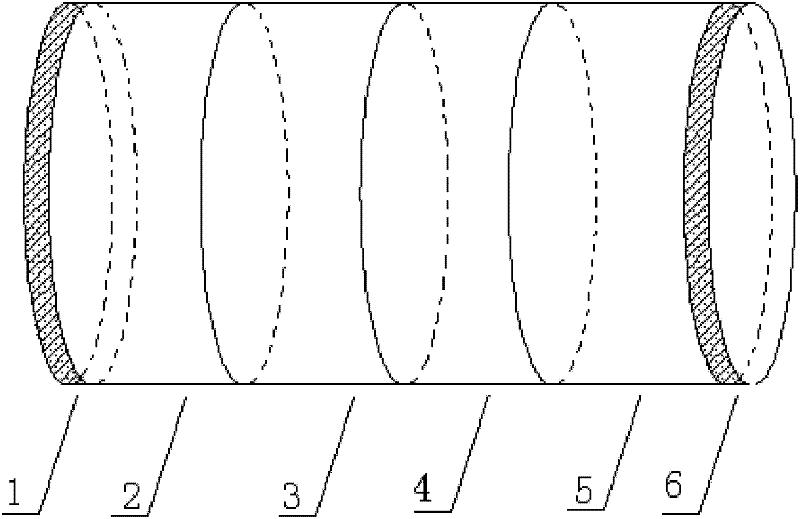

A laser crystal structure of an intracavity frequency-doubling laser

A laser crystal and intra-cavity frequency doubling technology, which is applied in the field of lasers to achieve the effect of reducing volume, facilitating miniaturization, and facilitating mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

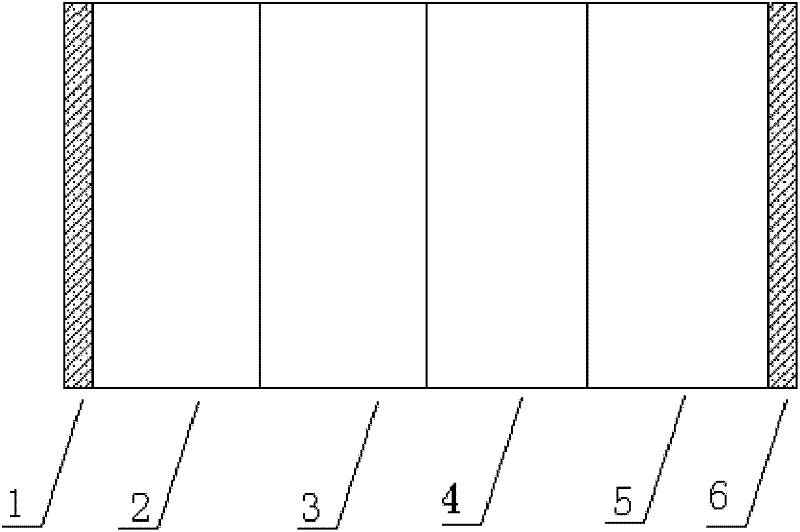

[0024] Such as figure 2 , the undoped crystal layers 2 and 4 are YVO 4 Crystal, doped crystal layer 3 is Nd:YVO 4 The crystal and the frequency doubling crystal layer 5 are KTP crystals. The undoped crystal layers 2, 4 and the doped crystal layer 3 are bonded together, and the undoped crystal layer 4 and the frequency doubling crystal layer 5 are bonded together by photoresist. The incident end is coated with an optical dielectric film with high transparency to 808nm and high reflection to 1064nm and 532nm; the output end is coated with an optical dielectric film with high reflection to 808nm and 1064nm and high transparency to 532nm.

Embodiment 2

[0026] Such as image 3 , the undoped crystal layers 2 and 4 are YAG crystals, the doped crystal layer 3 is Nd:YAG crystal, and the frequency doubling crystal layer 5 is LBO crystal. The undoped crystal layers 2, 4 and the doped crystal layer 3 are bonded together, and the undoped crystal layer 4 and the frequency doubling crystal layer 5 are bonded together by photoresist. The incident end is coated with an optical dielectric film with high transparency to 808nm and high reflection to 1064nm and 532nm; the output end is coated with an optical dielectric film with high reflection to 808nm and 1064nm and high transparency to 532nm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com