driven car axle

An automobile shaft and driven technology, applied in the field of automobile shafts, can solve the problems of high structural space requirements, complex braking equipment, insufficient braking effect, etc., and achieve the effect of reducing the structure size and small installation space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

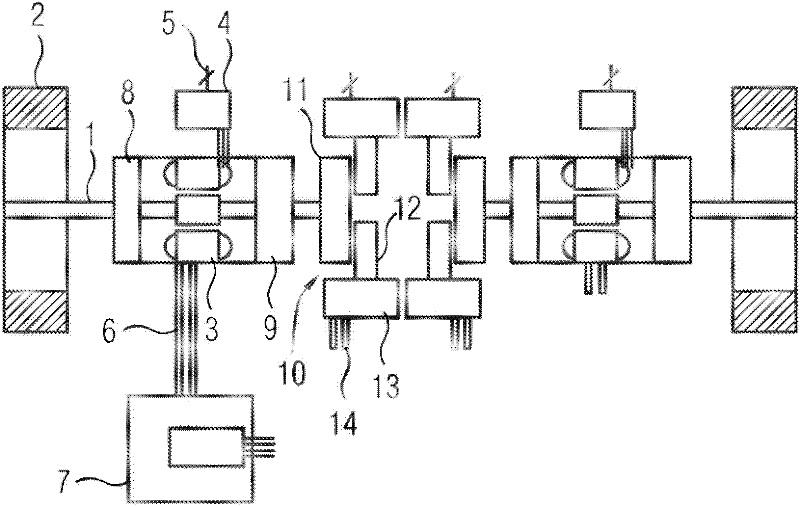

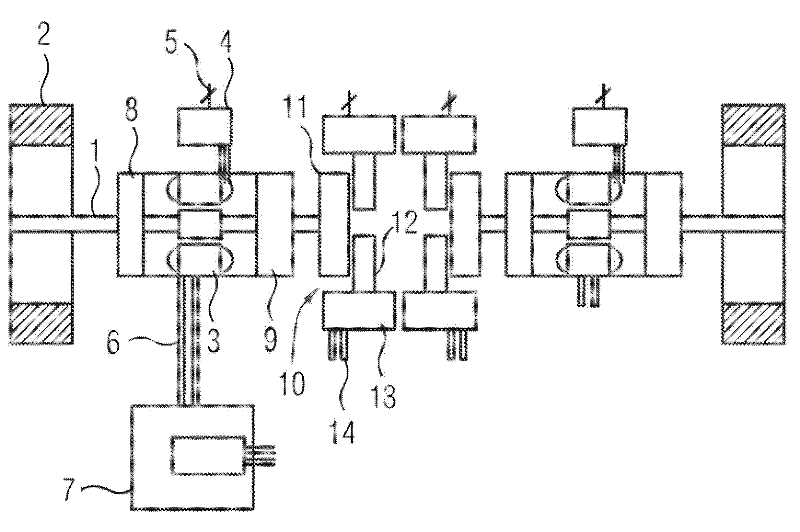

[0020] The motor vehicle 1 is symmetrically constructed and has at its ends each a wheel 2 which can be driven by means of an electric motor 3 . A control device (controller) 4 is provided for controlling and regulating the electric motor 3 , which is connected on the one hand to the electric motor 3 and on the other hand to the electrical connection 5 . The electric machine 3 has a cooling connection 6 which is connected via a heat exchanger to a schematically indicated heat store 7 , so that the electric machine 3 can be cooled while the heat store 7 is heated. The heat accumulator 7 can be used to regulate the temperature of the interior of the hybrid vehicle.

[0021] A transmission 8 is arranged between the wheels 2 and the electric machine 3 , by means of which the rotational speed of the electric machine 3 can be increased and the torque reduced. The transmission 8 is designed in such a way that the electric machine 3 runs in an optimum rotational speed range.

[0022...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com