Device and method for producing workpieces with surfaces consisting of rust-resistant metal

A technology for workpieces, non-ferrous metals, applied in the field of devices for performing the method, to achieve the effect of low manufacturing and simple cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

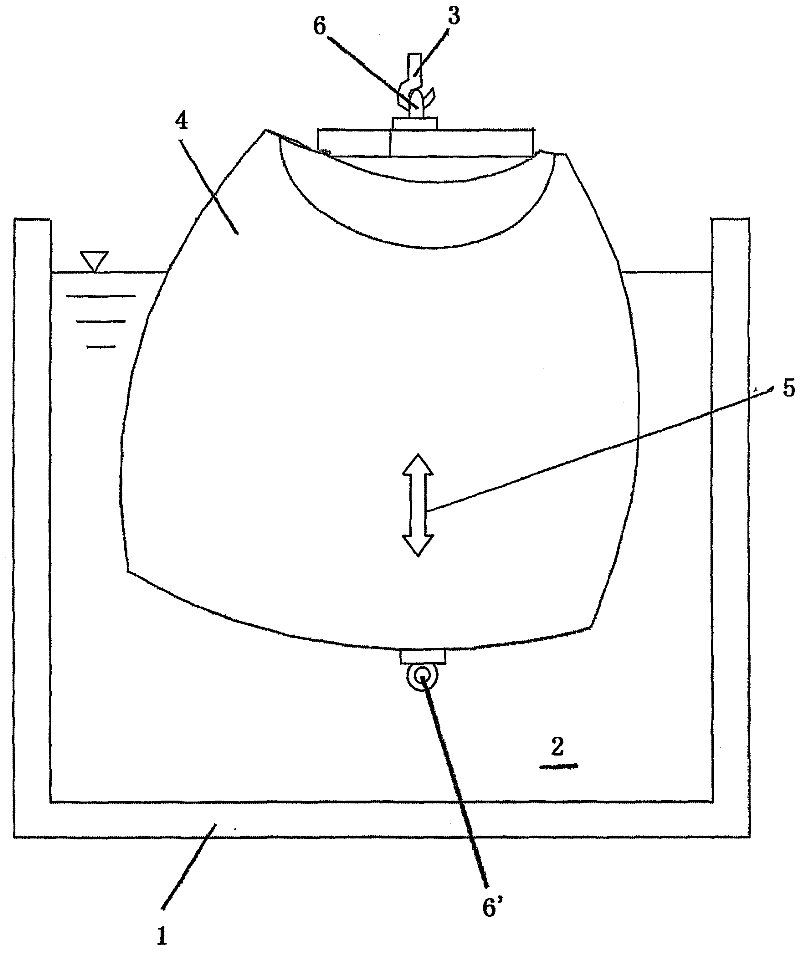

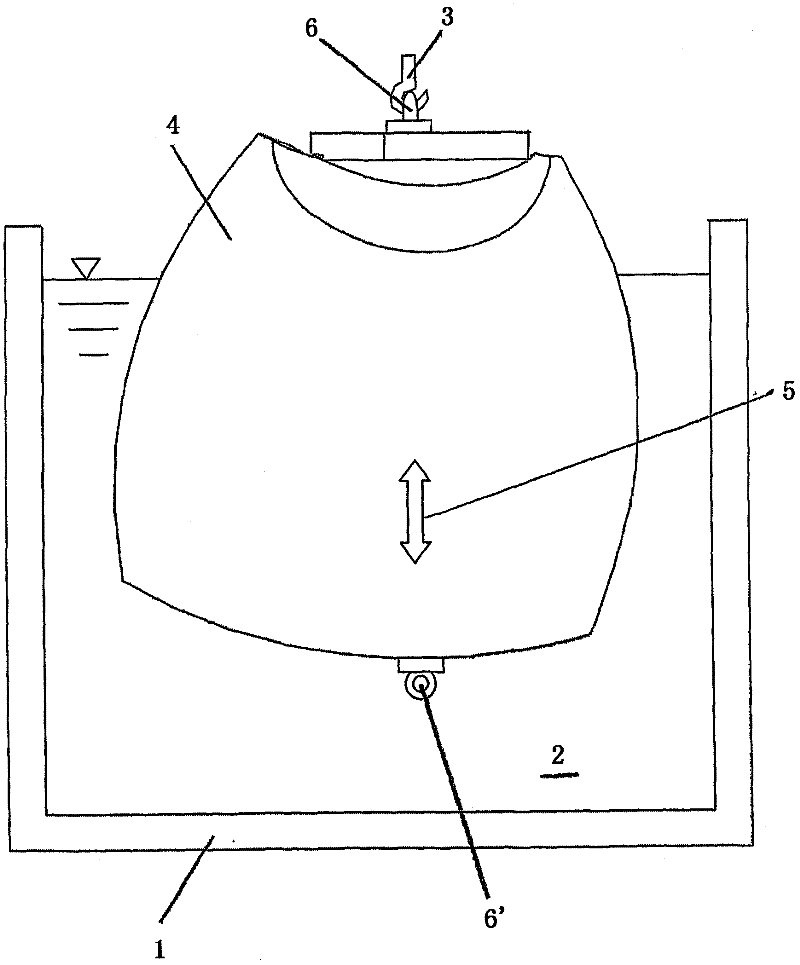

Method used

Image

Examples

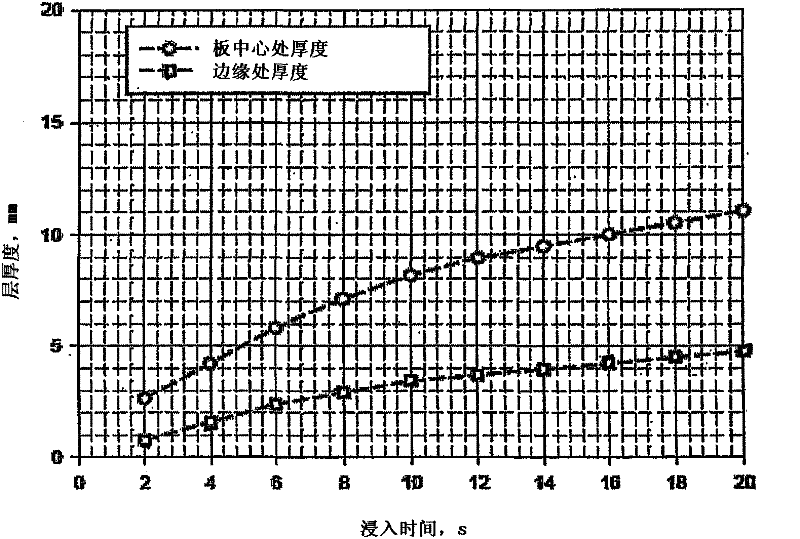

example 1

[0025] After preheating to 220° C., a turbine blade made of G20Mn5 QT was immersed in a molten steel made of GX4 CrNi 13-4QT at a temperature of 1550° C. A layer thickness of 8.2 mm (measured at the center of the plate) was obtained after an immersion time of 10 seconds. Here, the layer thickness at the edge was 3.5 mm. In order to have a uniform layer thickness of 5 mm, the turbine blade was dipped again. Subsequently, the surface is ground, whereby the desired shape, layer thickness and surface quality are obtained. Milling is also necessary in some cases.

example 2

[0027] Turbine blades made of G24Mn6 QT were dipped after preheating to 500° C. into a molten steel made of GX5 CrNiMo 19-11-2 at a temperature of 1500° C. By preheating, the immersion time can be extended without risk up to 20 seconds. Here, the desired minimum layer thickness of 5 mm has already been reached after one immersion. Subsequently, the surface is likewise ground in order to ensure the necessary quality.

[0028] The present invention is not limited to these examples. Instead, it can be applied to different types of workpieces, such as rotating bodies, worm extrusion shafts, etc. The molten steel used for the cladding can also consist of other materials, for example GX 4 CrNiMo 16-5-1, GX 2 CrNi 19-10 or similar steel types. The workpiece can also consist of other raw materials, wherein the same ASME or ASTM material can likewise be used both for the immersion melt and for the workpiece.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com