Imatinib mesylate tablet

A technology of imatinib mesylate tablets and imatinib mesylate, which is applied in the direction of pill delivery, medical preparations of non-active ingredients, organic active ingredients, etc., can solve the problems of strong viscosity, poor fluidity, and Poor pressure and other problems to achieve the effect of avoiding poor fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

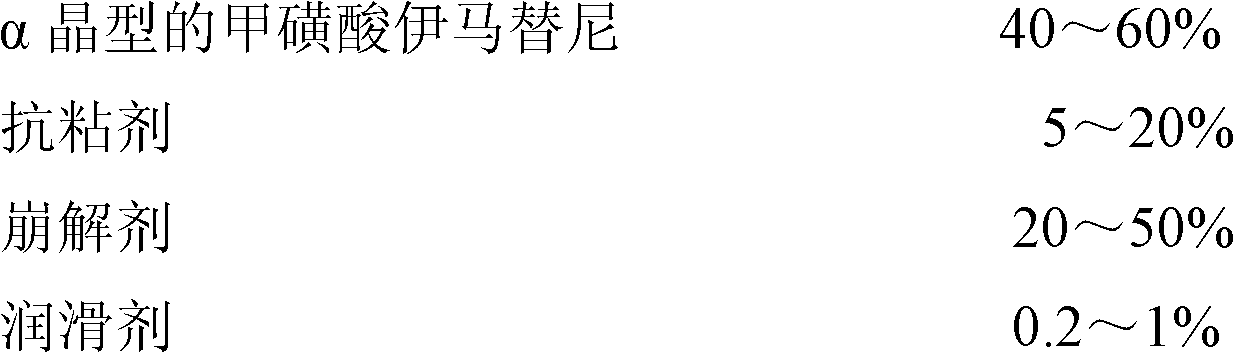

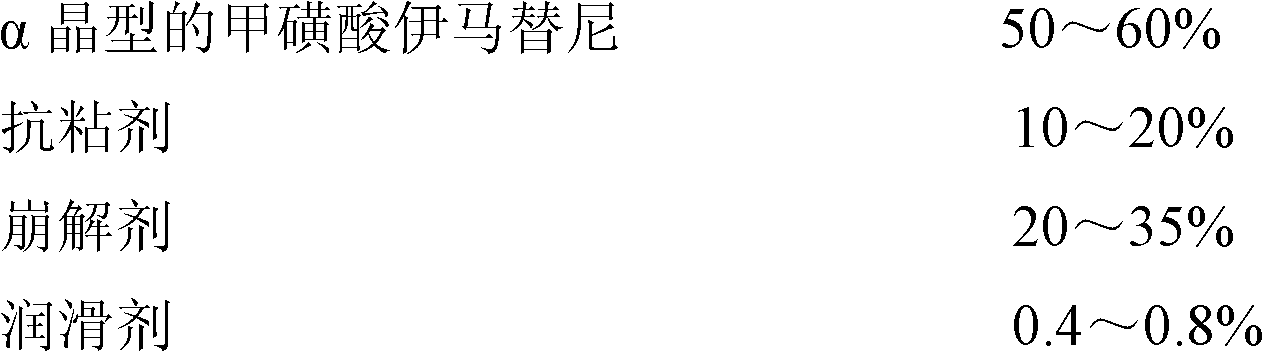

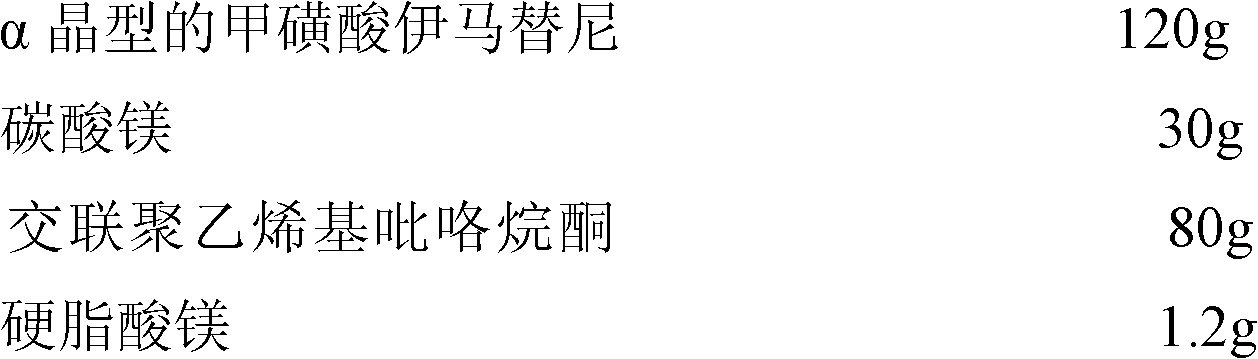

[0019] formula:

[0020]

[0021] First, mix the formula amount of imatinib mesylate and magnesium carbonate in α crystal form and magnesium carbonate evenly, then add the formula amount of cross-linked polyvinylpyrrolidone to mix evenly, then add 70ml of ethanol to granulate, dry and add stearin Magnesium acid mixed, compressed into 1000 tablets.

[0022] According to the determination method of the angle of repose of the United States Pharmacopoeia USP32, the angle of repose of the particles measured is 35°.

[0023] The hardness, friability, disintegration time and dissolution rate of the prepared tablets were measured by a four-purpose tester for tablets. The measurement results are as follows: hardness 10KG; friability 0.4%; disintegration time 2 min;

[0024] Table 1

[0025] time (minutes)

Embodiment 2

[0027] formula:

[0028]

[0029] First, mix the formula amount of imatinib mesylate in α crystal form and magnesium carbonate evenly, then add the formula amount of cross-linked polyvinylpyrrolidone to mix evenly, then add 50ml of water to granulate, dry and add stearin Magnesium acid mixed, compressed into 1000 tablets.

[0030] According to the determination method of the angle of repose of the United States Pharmacopoeia USP32, the angle of repose of the particles measured is 33°.

[0031] The hardness, friability, disintegration time and dissolution rate of the prepared tablets were measured by a four-purpose tester for tablets. The measurement results are as follows: hardness 12KG; friability 0.5%; disintegration time 2.5 min;

[0032] Table 2

[0033] time (minutes)

Embodiment 3

[0035] formula:

[0036]

[0037] First, mix the formula amount of imatinib mesylate and magnesium carbonate in α crystal form evenly, then add the formula amount of cross-linked polyvinylpyrrolidone to make the mix evenly, then add 50ml of isopropanol to granulate, dry and add Magnesium stearate is blended and compressed into 1000 tablets.

[0038] According to the determination method of the angle of repose of USP32 of the United States Pharmacopoeia, the angle of repose of the particles measured is 40°.

[0039] The hardness, friability, disintegration time and dissolution rate of the prepared tablets were measured by a four-purpose tester for tablets. The measurement results are as follows: hardness 8KG; friability 0.8%; disintegration time 1.5 min;

[0040] table 3

[0041] time (minutes)

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle of repose | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| angle of repose | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com