Soil conditioner

A soil conditioner and strain technology, which is applied in soil conditioning materials, organic fertilizers, fertilizer mixtures, etc., can solve the problems of improving soil structure, high cost of raw materials, and difficulty in adapting to different crops and soil conditions. The effect of bioavailability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

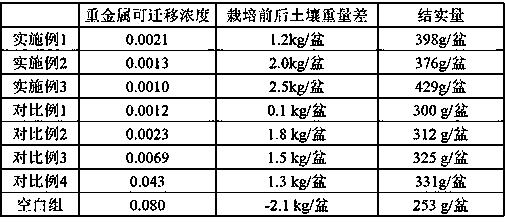

Examples

Embodiment 1

[0024] Mix 35 parts of straw granules, 30 parts of turmeric powder and 5 parts of attapulgite powder and then sterilize at 150°C, add 3 parts of strain powder to the sterilized mixture, stack it for 48 hours, add 10 parts of calcium chloride, 15 parts of diatomite, 5 parts of calcium hydroxide, 5 parts of apatite, and 5 parts of urea were mixed uniformly to prepare a soil conditioner.

Embodiment 2

[0026] Mix 50 parts of straw granules, 50 parts of scallop powder and 15 parts of attapulgite powder evenly, and then sterilize at 150°C. Add 5 parts of strain powder to the sterilized mixture, stack it for 48 hours, add 20 parts of ferric chloride, 10 parts of activated carbon, 10 parts of diatomaceous earth, 3 parts of calcium hydroxide, 4 parts of calcium carbonate, 10 parts of apatite, and 15 parts of urea were uniformly mixed to prepare a soil conditioner.

Embodiment 3

[0028] Mix 43 parts of straw granules, 39 parts of turmeric powder and 8 parts of attapulgite powder evenly, and then sterilize at 150°C. Add 3.6 parts of strain powder to the sterilized mixture, stack it for 48 hours, add 7 parts of ferric chloride, Mix 8 parts of calcium chloride, 5 parts of activated carbon, 6 parts of diatomaceous earth, 5 parts of zeolite, 4 parts of sodium sulfide, 4 parts of calcium carbonate, 8 parts of apatite and 9 parts of urea to prepare a soil conditioner.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com