Method for visually tracking plane abut-jointed weld beam by linear laser

A technology for visual tracking and butt welding, applied in laser welding equipment, welding equipment, metal processing equipment, etc., can solve problems such as reducing production efficiency, increasing the difficulty of image processing, and affecting tracking accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

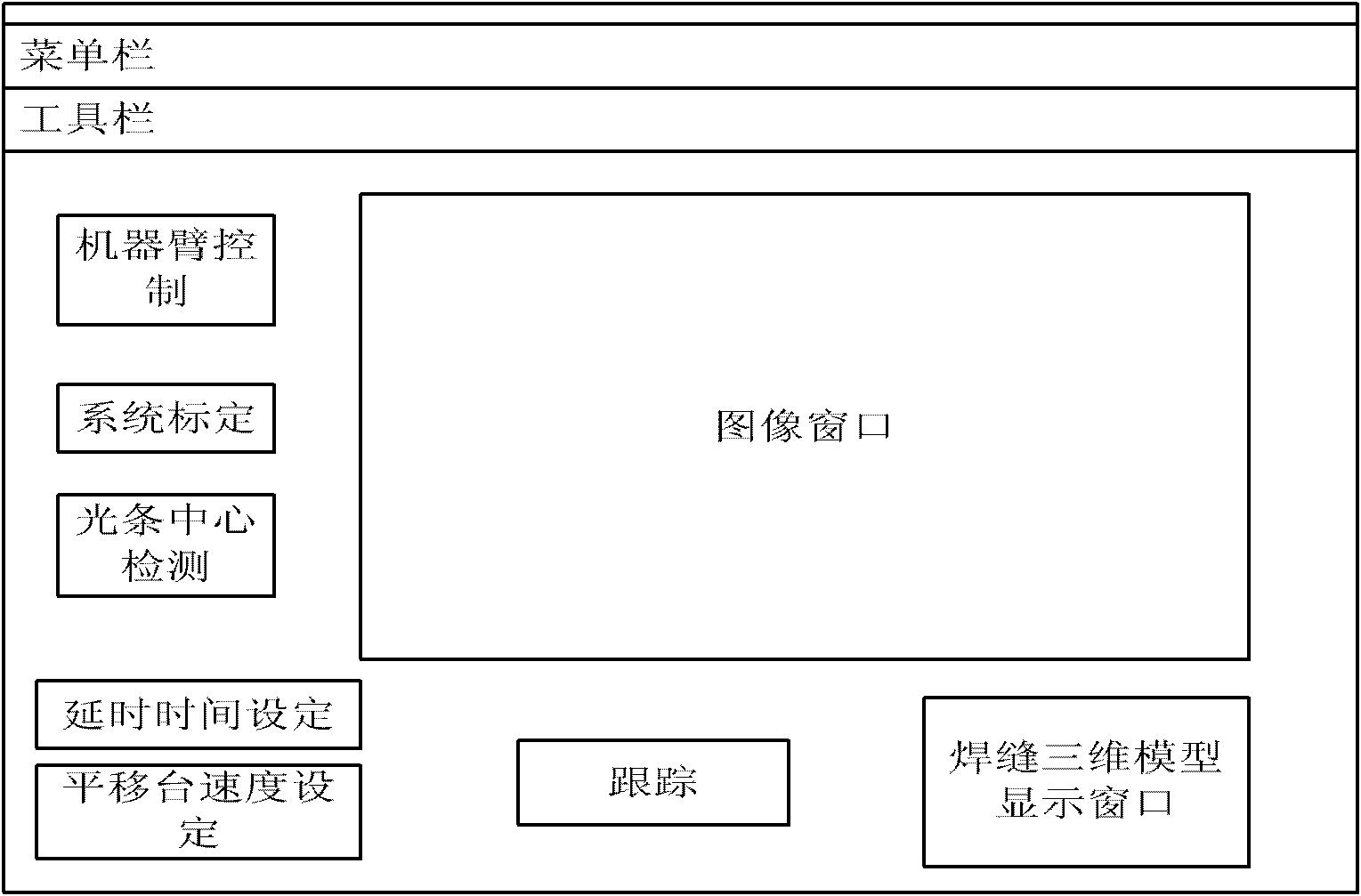

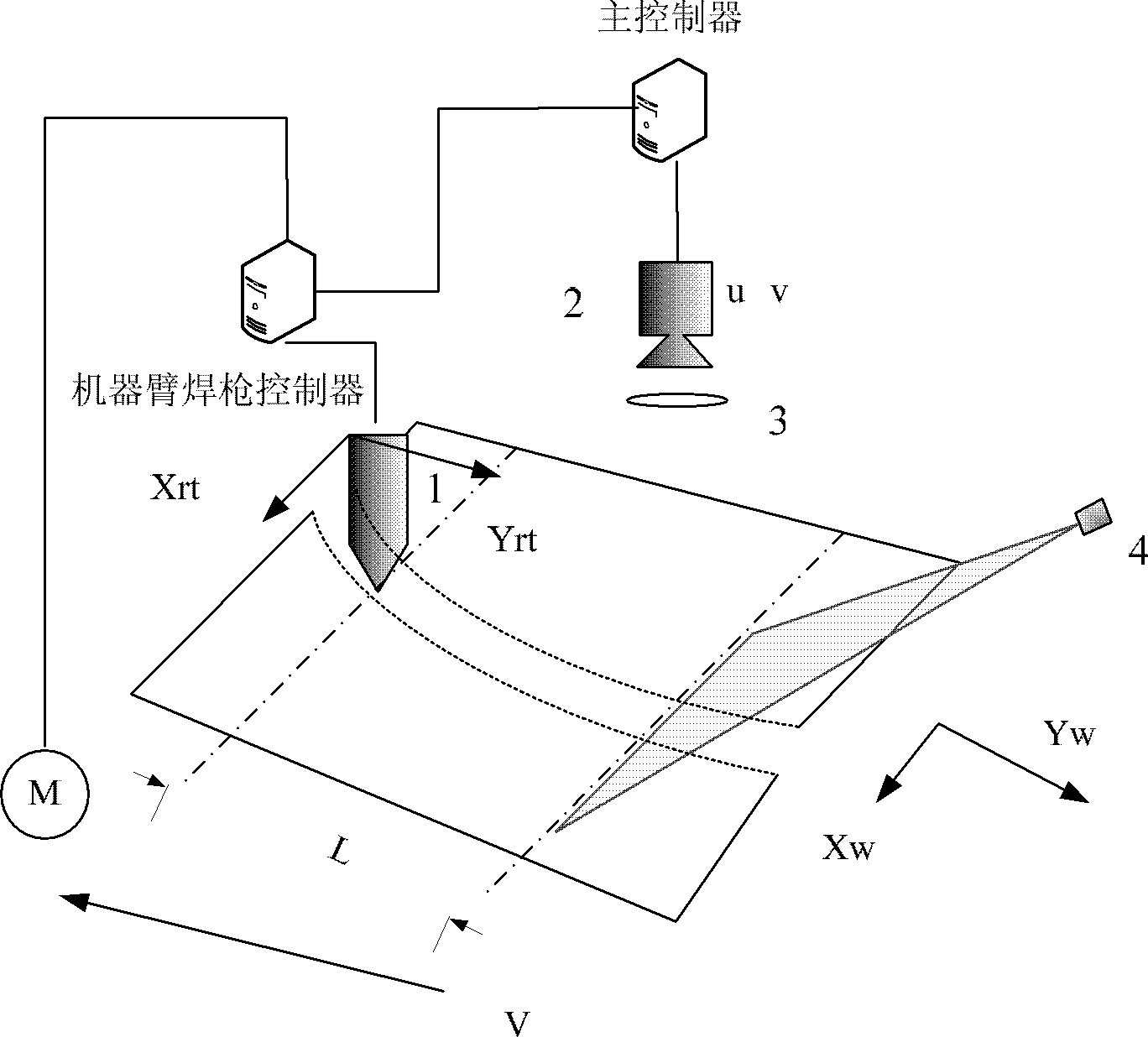

[0043] In order to improve the automation level of plane butt weld welding, the present invention develops a method for line laser vision tracking plane butt weld. The calibration technology algorithm has a small amount of code, fast operation speed, high precision, strong real-time performance, and good stability, which can improve the disadvantages of traditional measurement, reduce costs, and improve production efficiency.

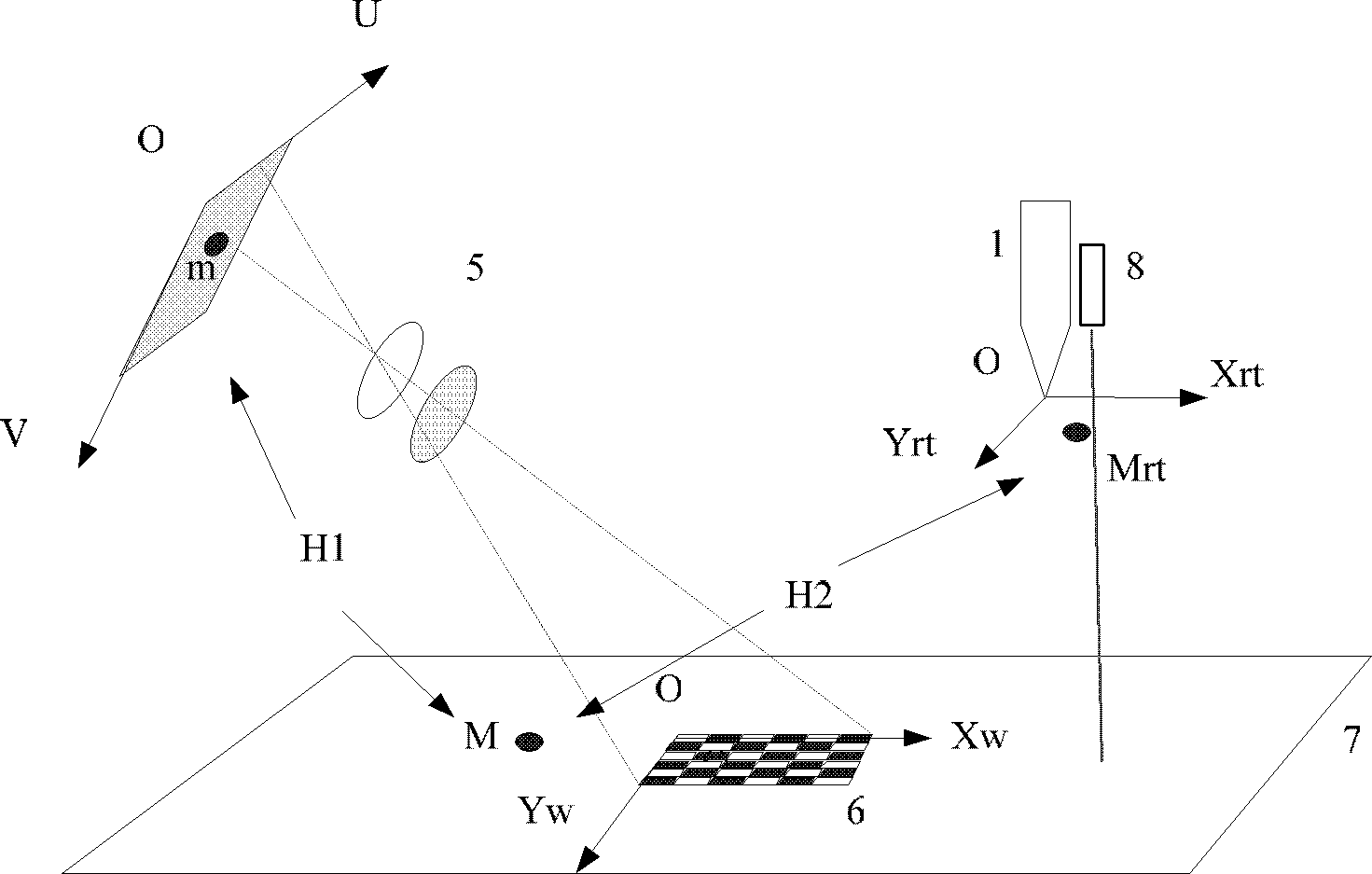

[0044]The invention uses a band-pass filter and a CCD to collect laser light strips to scan welding seam images, uses a central axis transformation algorithm to refine the light strips, projects the thinned skeleton, and determines the weld seam position by detecting continuous zero segments , determine the center of the weld by corresponding to the end points of the continuous zero area; automatically extract the coordinates of the checkerboard corner points and match their own corresponding world coordinates, complete the calibration of the camera and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com