Water cutting sound insulation enclosing mechanism of automotive interior ornament robot

A technology for robotic water and car interiors, applied in the field of machinery, can solve the problems of difficult to meet the requirements of new product cycle, high noise of water jet cutting, long purchase cycle, etc., to reduce external influences, save input costs, and improve production. quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

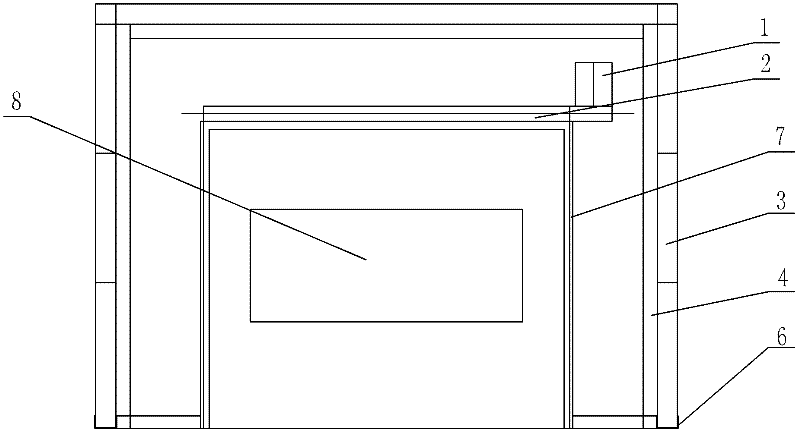

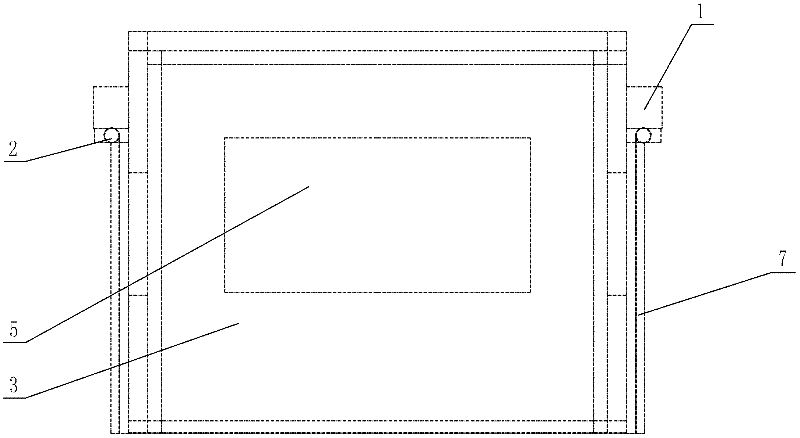

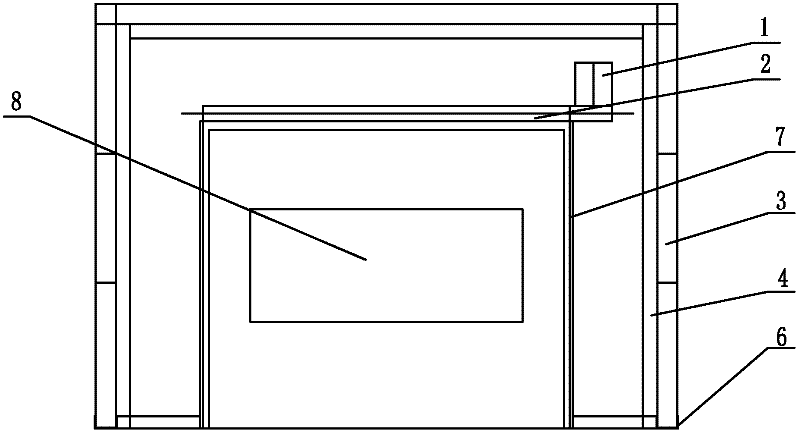

[0010] The present invention will be further described below in conjunction with specific drawings.

[0011] Such as Figure 1~Figure 2 Shown: the automotive interior robot water-cut sound insulation enclosure mechanism includes motor 1, rolling door 2, purification plate 3, skeleton 4, window 5, bottom frame 6, guide door frame 7, see-through window 8, etc.

[0012] The present invention comprises a framework 4 of frame type, and the front, back, left, right, up and down of the framework 4 are provided with purification plates 3 respectively, and the purification plates 3 enclose a space for workpieces to be cut by water jets; The side purification plate 3 is provided with a rolling door 2, and the two sides of the rolling door 2 are provided with a guiding door frame 7, and the rolling door 2 can be rolled up and down along the guiding door frame 7, and a 750W motor 1 is installed on the upper end of the rolling door 2; The purification plate 3 is provided with a window 5 w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com