Method for marking corner of vacuum heat collecting tube by using corner scales and product

A technology of vacuum heat collection tubes and corner scales, which is applied in heating devices, solar thermal devices, solar thermal power generation, etc., can solve the problem of low heat loss, achieve high marking accuracy, improve heat collection efficiency, and have strong heat transfer and isothermal capabilities Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

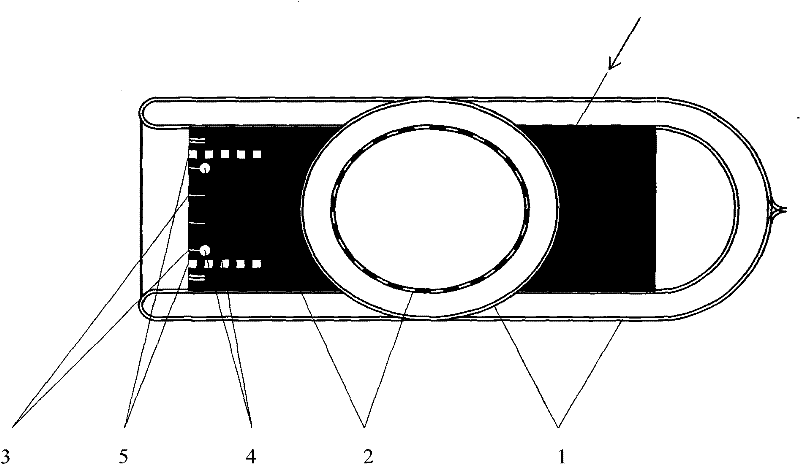

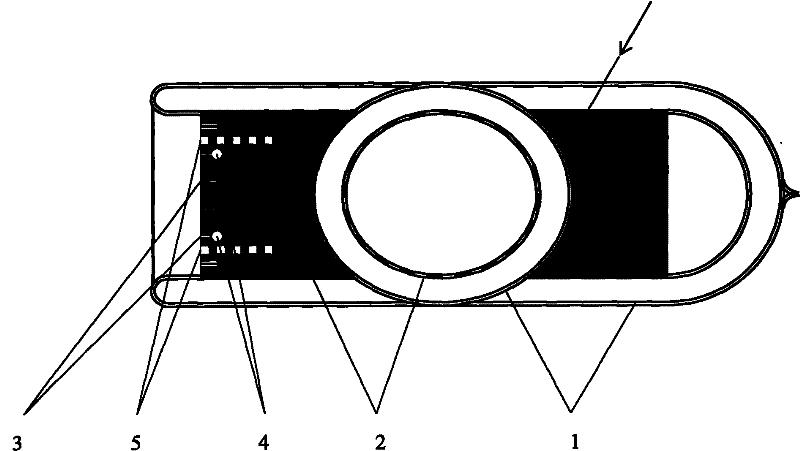

[0012] figure 1 An example of the present invention is given. figure 1 In this method, two glass tubes with round mouths at one end are used to cover the glass tube 1 and the inner glass tube 2 in a concentric nesting arrangement, and the outer surface of the inner glass tube 2 is made of a selective absorption film by vacuum sputtering, and at the openings of the two glass tubes 1 and 2 Melting and forming a vacuum between the two layers of glass tubes to form a vacuum heat collecting tube with corner scale marks. The corner scale bar mark 3 uniformly distributed according to the 360-degree circumferential angle is formed by not coating the outer surface area of the inner glass tube 2 to form chromatic aberration. The end point 4 of part of the bar mark 3 is marked with a text corner scale mark. Usually these words are 4, 7, 10, 1, can formulate standard regulation: in 4, 7, 10, January, make 4, 7, 10, 1 be at the topmost of heat collecting tube. The surface of the coati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com