Lifting type silo comprehensive monitoring mechanism

A comprehensive monitoring and lifting technology, applied to clockwork mechanism, measuring device, instrument, etc., can solve the problem of reducing the number of control equipment, and achieve the effect of convenient and fast driving, convenient maintenance, simple and practical structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

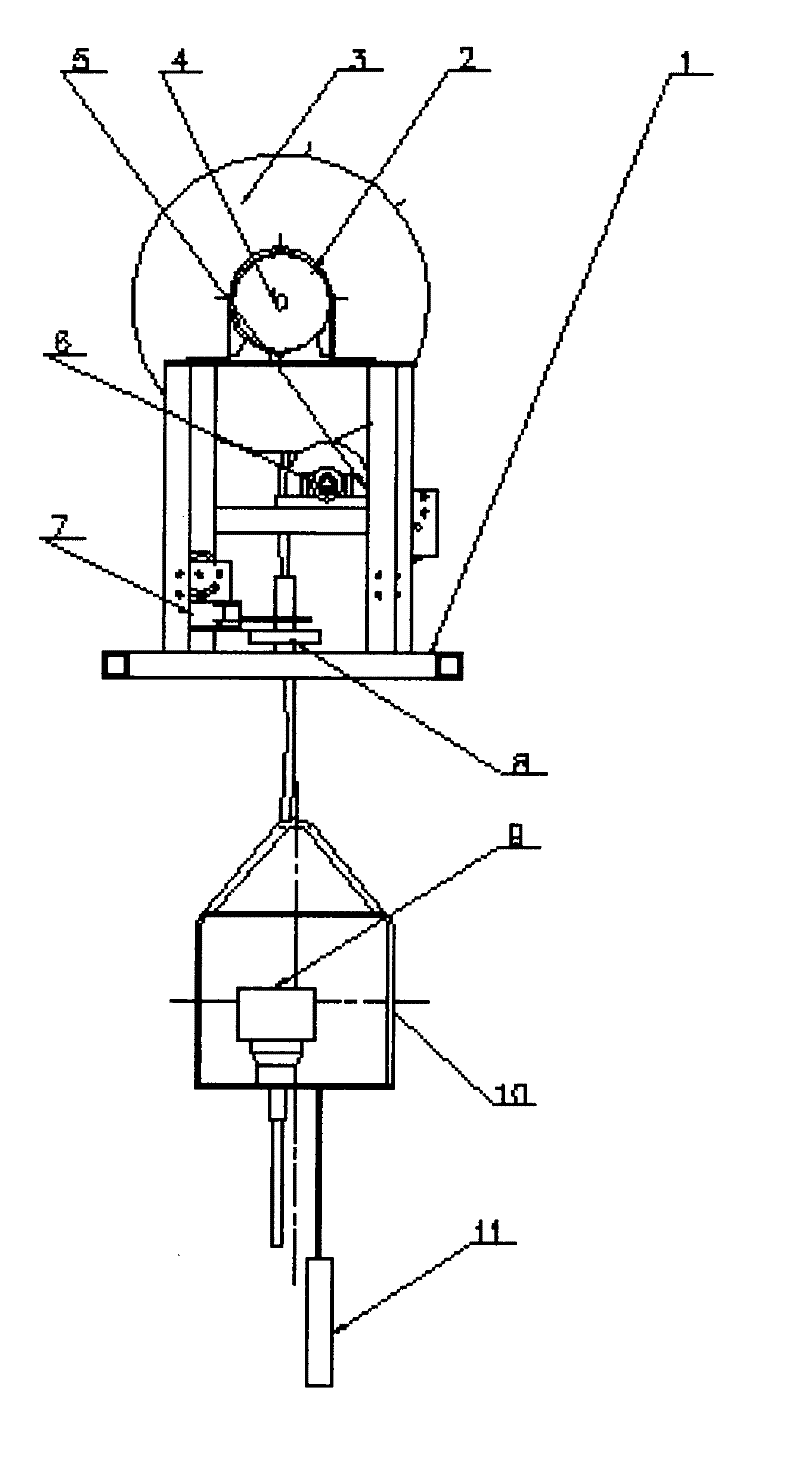

[0008] The comprehensive monitoring mechanism of the lifting silo can be controlled locally by the control handle, and can also be controlled on the remote host computer; manual control is relatively simple, and the controller determines the forward and reverse rotation, operation and stop of the motor according to the observation situation; when on the host computer , is connected to the PLC communication module through the configuration software; the PLC program controls the motor to run forward when it is powered on, and drives the drum to rotate forward to release the cable, and the hanging basket moves downward. The cable drives the nylon roller to rotate by friction, and the nylon roller shaft The eccentric wheel at one end rotates synchronously. Every time the eccentric wheel rotates, it will touch the micro switch once, which will generate a counting switch signal, which can calculate the descending height of the cable, and convert the coal level height through related f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com