Accurate detection device for sliver of carding machine

A detection device and a technology of a carding machine, which are applied to measuring devices, mechanical devices, deburring devices, etc., can solve problems such as affecting the sliver leveling effect, affecting the accuracy of signals, and small output signal volume, and achieving accurate and reliable detection. , Improve the accuracy and reliability, eliminate the effect of axial clearance error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

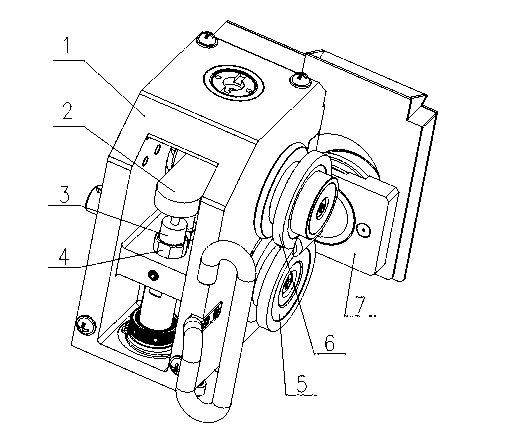

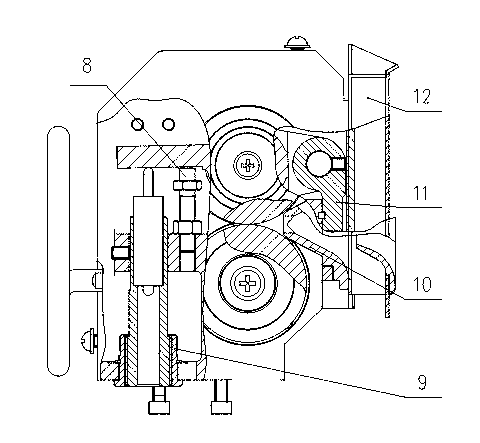

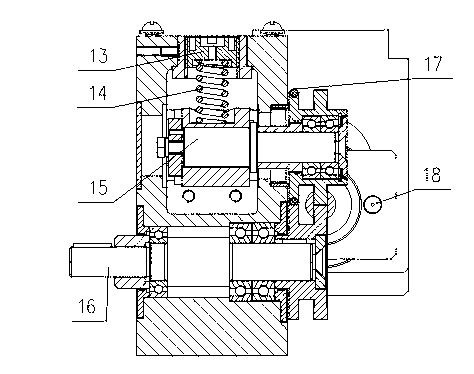

[0029] The present invention is an accurate detection device for cotton sliver of a carding machine, comprising a detection box, a bell mouth on the detection box, a detection mechanism for inducting changes in the thickness of the sliver in the bell mouth, and a sensor connected to the detection mechanism, characterized in that: the detection A bell mouth fixed adjustment plate is arranged on the box body, the tail of the bell mouth adopts an open structure, and is fixed on the bell mouth fixed adjustment plate by magnetic steel, and the detection mechanism includes an upper pressure roller, an upper pressure roller Rotary support shaft, lower pressure roller, lower pressure roller rotation shaft, the upper pressure roller is connected to the rotation support shaft of the upper pressure roller through bearings, the lower pressure roller is fixed on the rotation shaft of the lower pressure roller through a key, and the upper and lower pressure rollers adopt double In the form o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com