Long-stroke plate-type lead shearing damper

A technology of large stroke and damper, applied in building components, anti-vibration and other directions, can solve the problems of inability to meet engineering requirements and small stroke, and achieve the effects of simple structure, reduced contact area, and stable damping force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

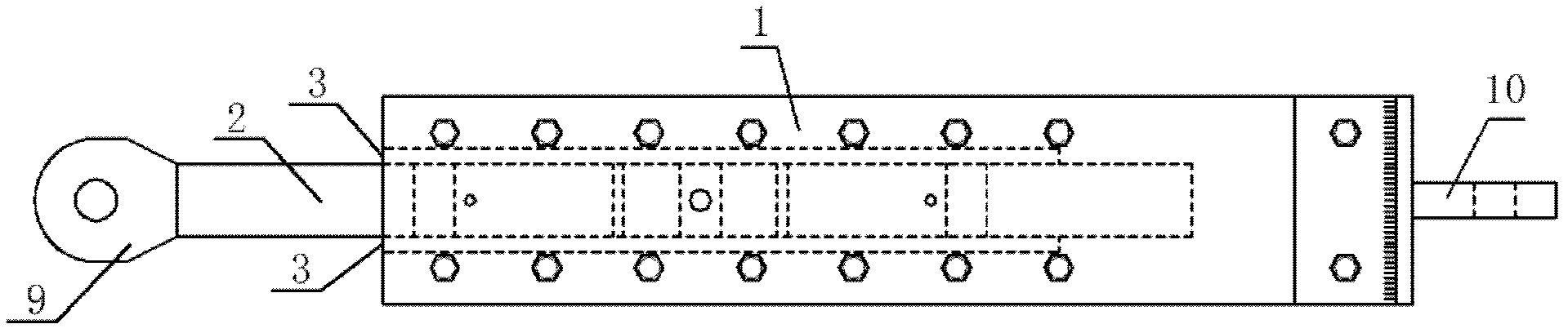

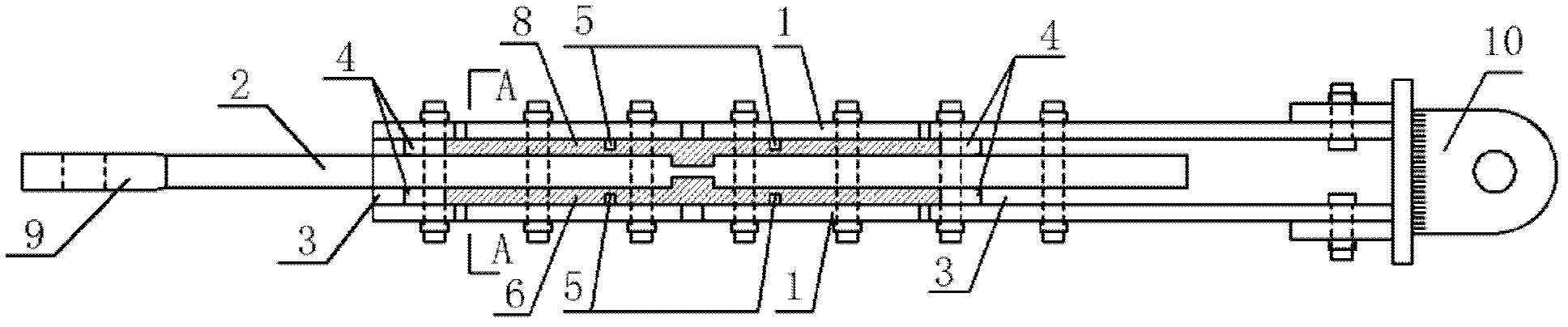

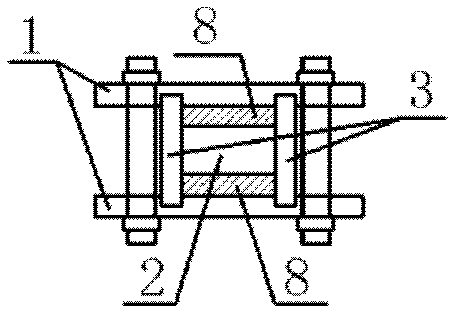

[0021] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0022] see Figure 1 to Figure 5 As shown, it includes a cover plate 1, a sliding plate 2, a side baffle 3 and a block 4; the two cover plates 1 are placed opposite to each other on the sliding plate 2; the side baffle 3 is between the two cover plates 1 and is close to the Both sides of the sliding plate 2; wherein, two stoppers 4 are welded along the length direction on the cover plate 1; two grooves 6 are arranged in the center of the sliding plate 2; the cover plate 1, the sliding plate 2, and the side stop are fixed by bolts The plate 3 and the block 4 form two "cavities"; there is a lead block 8 formed after the molten lead is poured into the cavity from the lead filling hole 7 to be solidified in the cavity; when the sliding plate 2 reciprocates, the concave Shearing the lead weight 8 in the groove 6 consumes energy.

[0023] Two lead...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com