Method for automatically transferring material drug freeze-drying tray to freeze drier ply

A lyophilizer and API technology, which is used in the preliminary treatment, drying, transportation and packaging to promote the drying of solid materials, can solve the problems of tray contamination and adverse sterility, and achieve high sterility and ensure no Bacterial effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

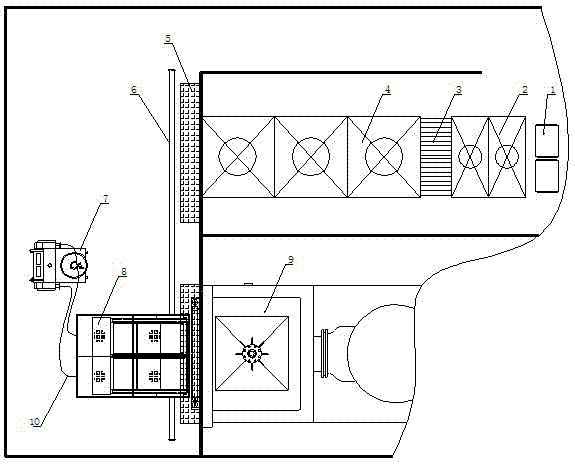

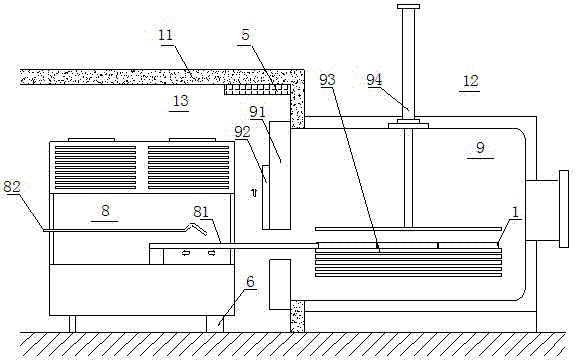

[0016] In order to make the present invention more comprehensible, a preferred embodiment is described below in detail with the accompanying drawings.

[0017] Combine figure 1 , The present invention provides a method for automatically transferring the freeze-drying tray of APIs to the layer of the freeze-drying machine, and the steps are:

[0018] Step 1. Put the tray 1 into the automatic dish washer 2 located in the clean room and clean it;

[0019] Step 2. Transfer the cleaned tray 1 to the tray sterilization tunnel oven 4 through the chain plate 3 for sterilization and drying;

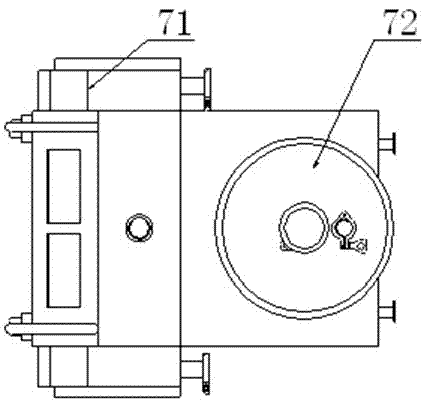

[0020] Step 3. After the tray 1 is sterilized and dried, the automatic tray-in / out device 8 moves along the track 6 to the sterilization tunnel oven 4 for docking, and the tray 1 is protected by the A-level unidirectional submerged protection device 5 located above the docking area. take out;

[0021] Step 4. Combine figure 2 , The automatic disk access device 8 moves along the track 6 to the door of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com