Method for monitoring closed circular coal yard optical fiber temperature and optical fiber monitoring device

An optical fiber temperature and monitoring device technology, which is used in measuring devices, thermometers, thermometers with physical/chemical changes, etc. Large, simple interface, data transmission and processing simplification effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

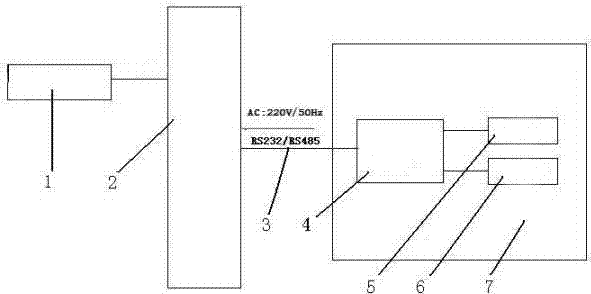

[0018] exist figure 1 Among them, the optical fiber monitoring device includes an optical fiber temperature-sensing cable 1, one end of the optical fiber temperature-sensing cable 1 is connected to an optical fiber sensing analyzer 2, and the optical fiber sensing analyzer 2 is connected to a host computer 4 through an Ethernet 3, and the host computer 4 is connected to a printer 6 and display 5.

[0019] Optical fiber sensor analyzer 2 temperature measurement range -200℃~+450℃, measurement distance range 2km / 4km / 10km / 15km / 30km optional, measurement response time 12s-40s, optical fiber sensor analyzer 2 through RS485 / 232, Or CAN, or Ethernet 3 interfaces are connected to the fire alarm controller to form a complete circular coal yard safety monitoring system.

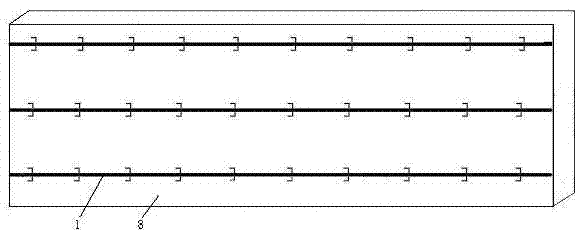

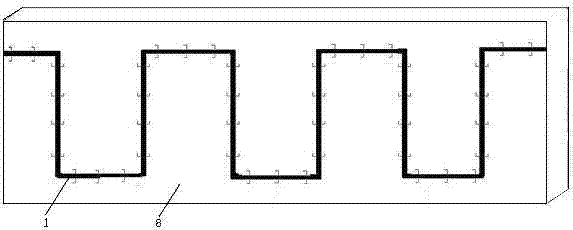

[0020] The appearance of the optical fiber temperature sensing cable 1 is circular, the minimum bending radius is 30mm, and the temperature range is -40-200°C. The contact area between the optical fiber temperature sen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com