Assembled radiating fin with transistor

A transistor and semiconductor technology, applied in semiconductor devices, semiconductor/solid-state device components, electric solid-state devices, etc., can solve the problems of limited heat dissipation, susceptibility to static electricity, affecting service life, etc., and achieves simple structure and good breakdown resistance. , good heat dissipation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with the accompanying drawings.

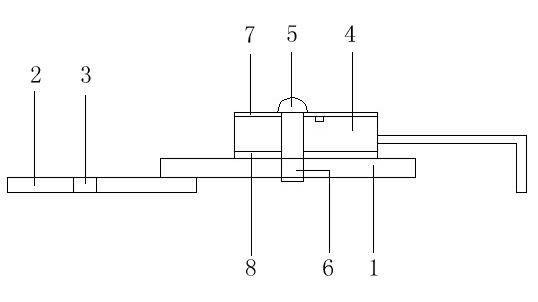

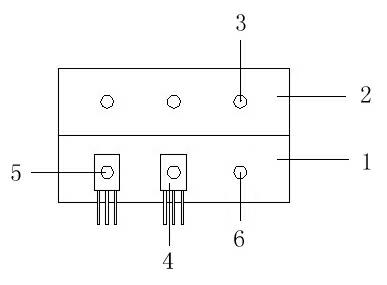

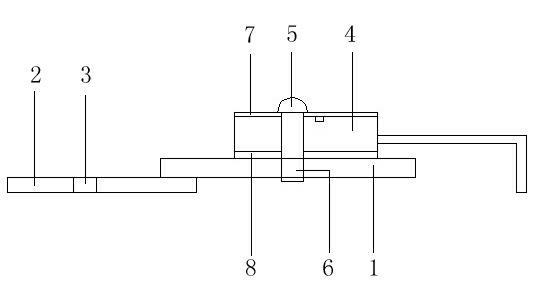

[0013] like figure 1 , figure 2 As shown, the main body of the heat sink is composed of a copper heat dissipation surface 1 and an aluminum close-fitting surface 2, and the aluminum close-fitting surface 2 is provided with fixing screw holes 3, which are connected to the aluminum close-fitting surface 2 by screws. Fix the screw hole 3 and the connecting screw hole reserved on the circuit board, connect the aluminum close-fitting surface 2 to the circuit board, the copper heat dissipation surface 1 is stacked on top of the aluminum close-fitting surface 2, and the copper A semiconductor triode 4 is provided on the heat dissipation surface 1, and the semiconductor triode 4 is connected to the mounting screw hole 6 on the copper heat dissipation surface 1 through a screw 5. The surface of the semiconductor triode 4 is provided with an insulating silica gel protective la...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com