Connection array and battery cover of lithium ion battery and method for connecting connection array with battery cover

A technology for connection bars and battery covers, which is applied to battery components, circuits, electrical components, etc., can solve problems such as the inability to increase the size of the connection bar, increase the internal resistance of the battery, and battery failure, and achieve high-power charging and discharging. Safety performance, increased contact area, and improved reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

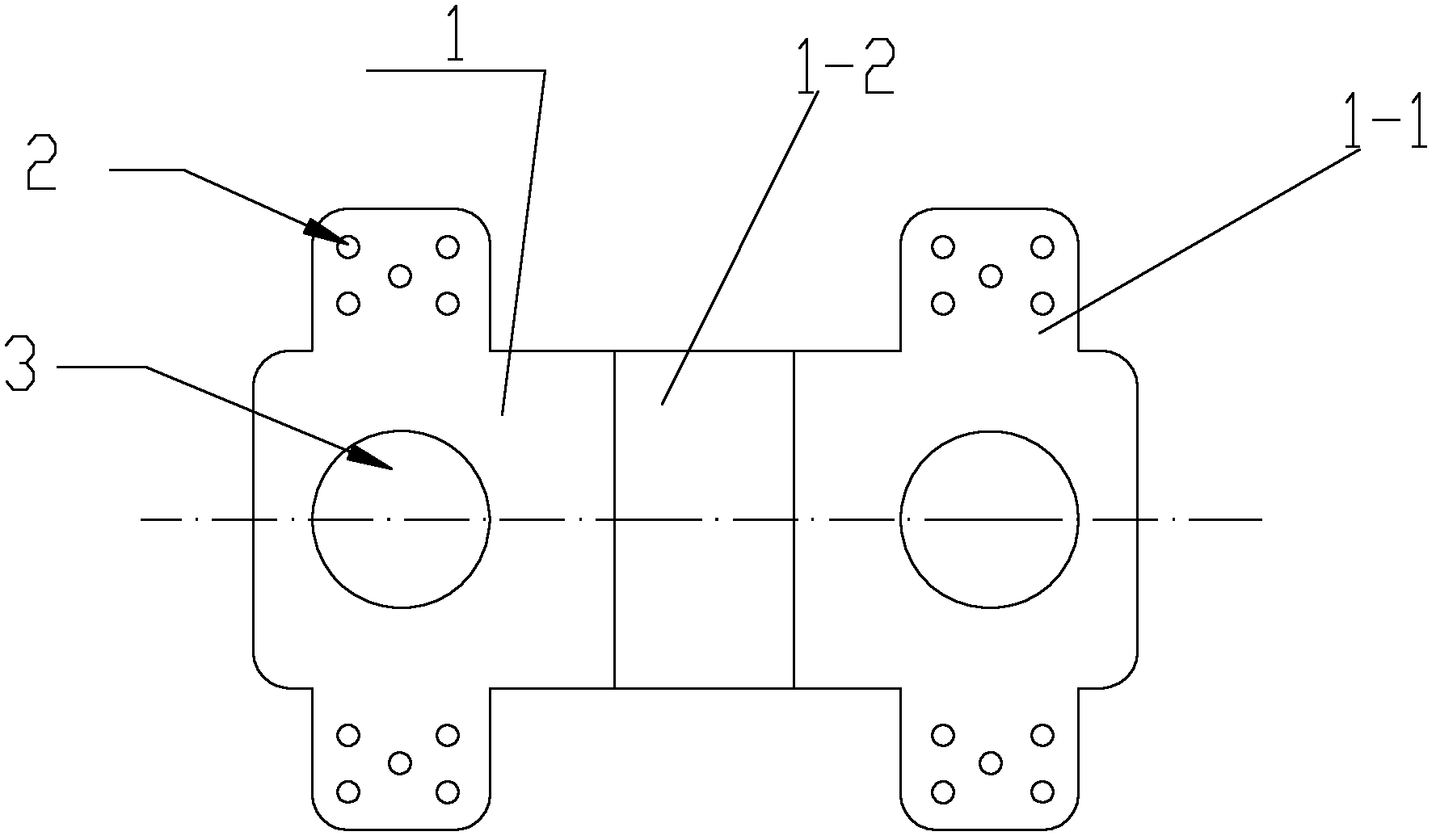

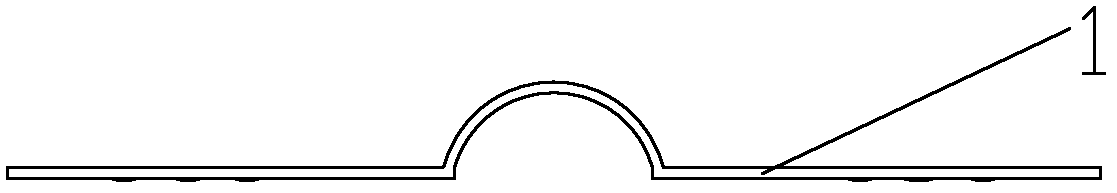

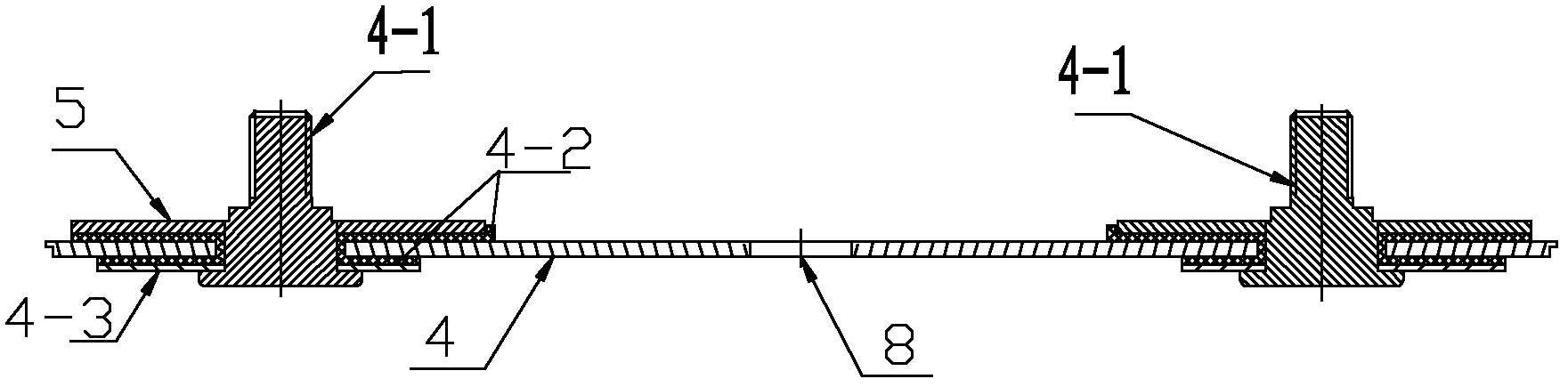

[0019] The specific implementation manner of the present invention will be described in detail below in conjunction with the accompanying drawings and preferred embodiments. As shown in the figure, a connecting row and battery cover of a power lithium battery includes a connecting row 1 and a battery cover 4 with an explosion-proof valve 8. The connecting row is in the shape of a thin plate, and welding ears are symmetrically provided on both sides of the rectangular thin plate. 1-1, and connected with the connecting row to form an overall "I" shape, the welding ear is provided with a positioning groove 2, and the number of the positioning grooves is five, of which there are two on the upper and lower sides, and one in the middle. The connecting row is symmetrically provided with a pole via hole 3 along the axial center line; the battery cover includes a battery cover plate 4, positive and negative poles 4-1, upper and lower sealing positioning gaskets 4-2, flat terminals 5 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com