Automatic tobacco curing room

A flue-cured tobacco room, automatic technology, applied in tobacco, tobacco preparation, application, etc., can solve the problem of pollutant discharge, achieve automation, save manpower and material resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

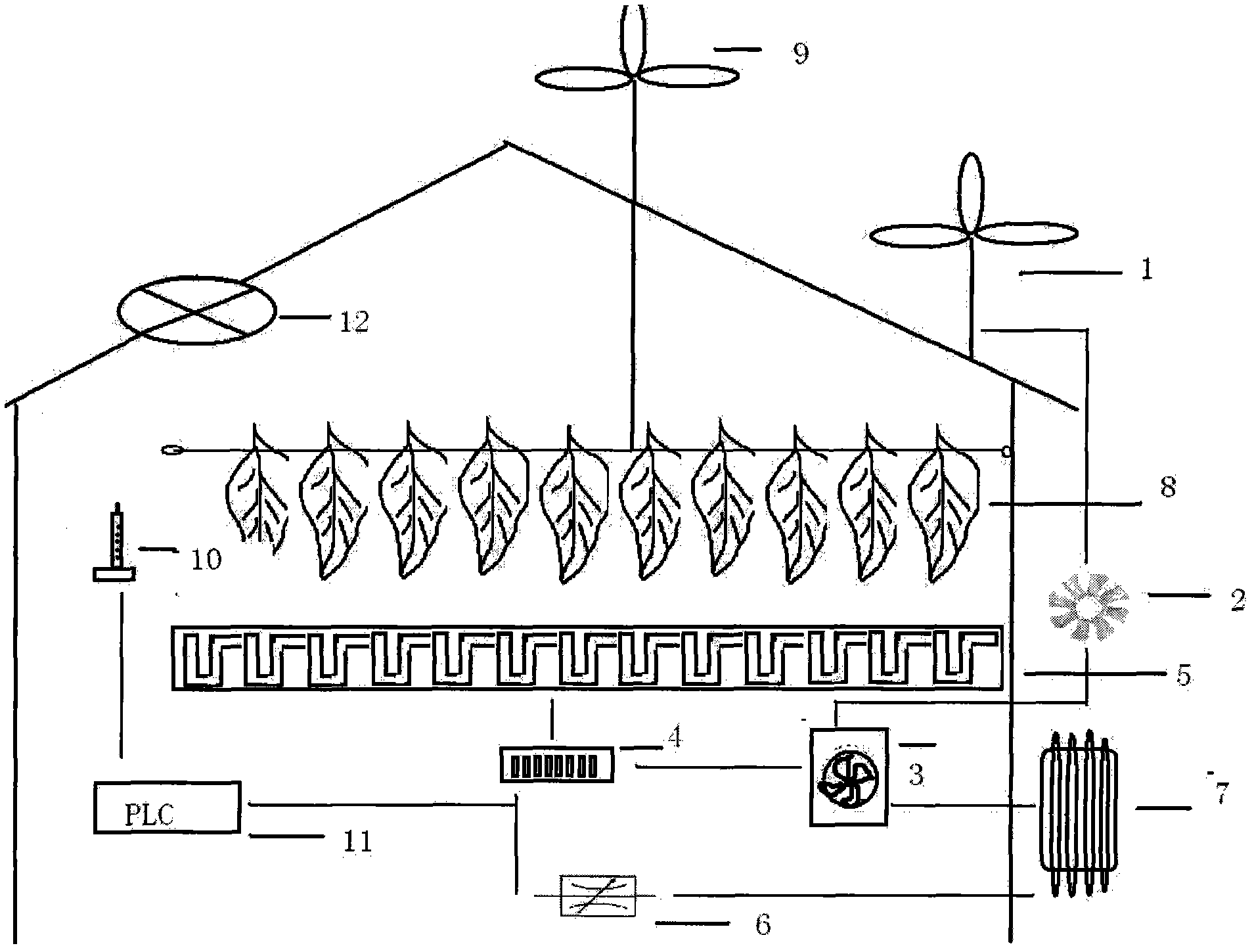

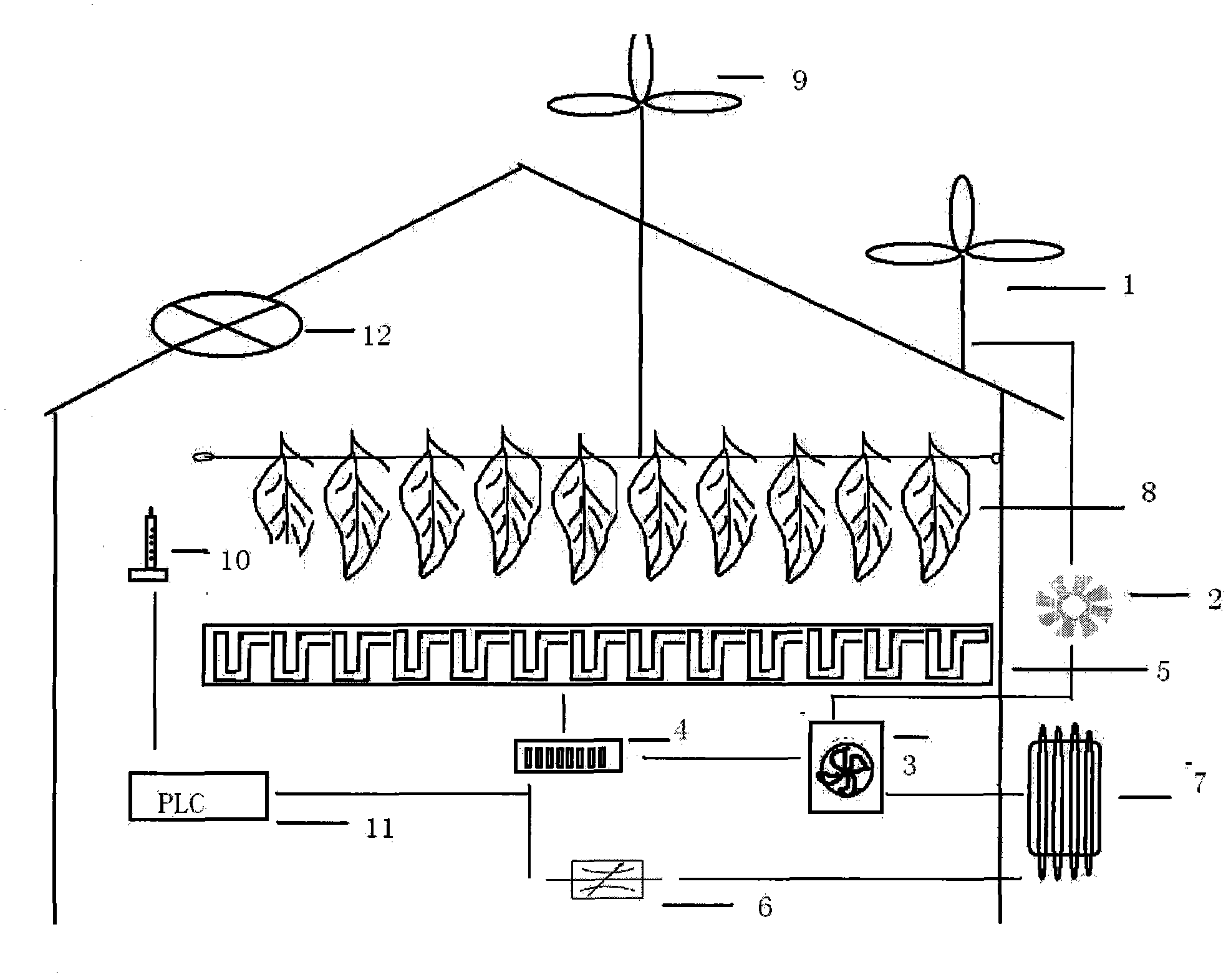

[0011] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0012] In the accompanying drawings, the wind blade 1 (1) collects natural wind, and the natural wind blows the wind blade to rotate, and the wind blade transmits kinetic energy to the planetary transmission (2), and the planetary transmission drives the centrifugal compressor (3) to run, realizing the working fluid The gas phase changes, and the centrifugal compressor compresses the working fluid, turning the working fluid into a high-pressure and high-temperature gaseous state and sending it to the condenser (4), where the working medium is liquefied to release heat, and the condenser transfers the heat to the heated kang (5), and the working medium becomes a low-pressure, low-temperature liquid state It flows into the throttling valve (6), under the throttling action of the throttling valve, the working medium is pressurized and becomes a high-pressur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com