Thermal cracking resistant zeolite membrane and method of fabricating the same

A production method and separation membrane technology, applied in semipermeable membrane separation, chemical instruments and methods, membranes, etc., can solve problems such as no research and development solutions, and achieve the effects of reducing production costs, reducing thermal cracking, and shortening production time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0104] After dissolving water glass (Water Glass), sodium aluminate (Sodium Aluminate), and sodium hydroxide (NaOH) in water to produce an aqueous solution, it stirred at 28 degreeC for 24 hours, and produced the hydrothermal solution. The total volume of the hydrothermal solution is 500ml, the Al in the hydrothermal solution 2 o 3 , SiO 2 、Na 2 O and H 2 The moles of O are 1, 2, 4.5, and 600, respectively.

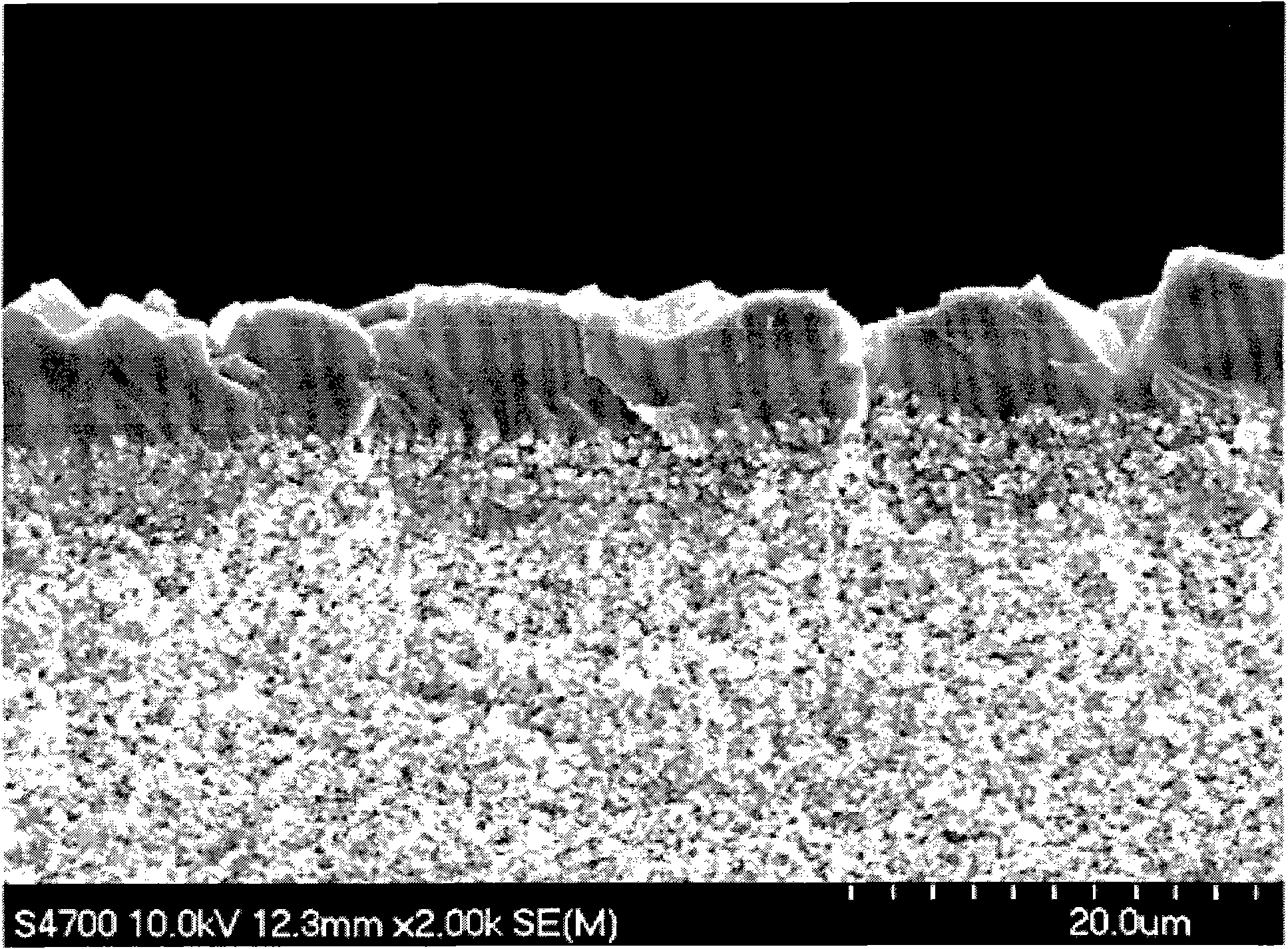

[0105] Use 20g of water and 90g of alumina balls with a diameter of 1mm to vibrate and pulverize 1g of NaA zeolite powder at a speed of 500cylces / min for 24 hours and centrifuge at a speed of 6000rpm for 10 minutes, then dilute with 200g of water to produce a weight percentage of 0.1 Slurry of custody seed crystals in weight percent. After extracting 4 ml from the prepared stored seed crystal slurry, it was diluted with 150 g of water to prepare a 0.0026% by weight seed crystal. The average particle size of the produced seed crystals is 0.15μm (150nm), please refer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com