Chloropropanediol purifying apparatus and production method thereof

A technology of chloroglycerol and production method, applied in the chemical industry, can solve the problems of low conversion rate of raw materials, poor economic benefit, low product yield and the like, and achieve the effects of strong catalytic activity, reduction of by-products, and increase of contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

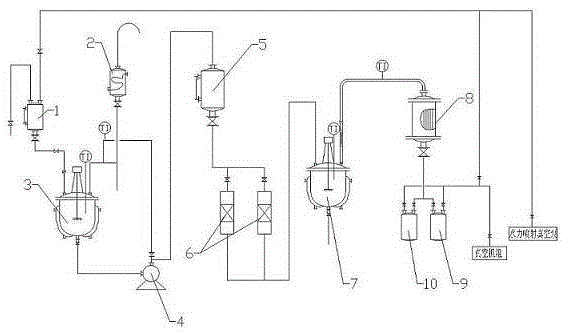

[0037] Example 1, such as figure 1 As shown, a chlorinated glycerol purification device comprises a hydrolysis kettle 3, a hydrolyzate head tank 5, an ion exchange column 6, a distillation kettle 7, and a condenser 8 connected through pipelines successively. On the output pipeline of the condenser 8, A front fraction tank 10 and a finished product tank 9 are connected, and the front fraction tank 10 and the finished product tank 9 are respectively connected with a vacuum unit.

[0038] A circulation pipeline is installed between the lower end and the upper end of the hydrolysis kettle 3, and a circulation pump 4 is installed on the circulation pipeline.

[0039] A glass condenser 2 is connected to the circulation pipeline; the liquid inlet pipe of the hydrolyzate head tank 5 communicates with the circulation pipeline.

[0040] The top of the hydrolysis kettle 3 is communicated with an elevated tank 1, and the elevated tank 1 is connected with a hydraulic jet vacuum pump throu...

Embodiment 2

[0059] Example 2, such as figure 1 As shown, a chlorinated glycerol purification device comprises a hydrolysis kettle 3, a hydrolyzate head tank 5, an ion exchange column 6, a distillation kettle 7, and a condenser 8 connected through pipelines successively. On the output pipeline of the condenser 8, A front fraction tank 10 and a finished product tank 9 are connected, and the front fraction tank 10 and the finished product tank 9 are respectively connected with a vacuum unit.

[0060] A circulation pipeline is installed between the lower end and the upper end of the hydrolysis kettle 3, and a circulation pump 4 is installed on the circulation pipeline.

[0061] A glass condenser 2 is connected to the circulation pipeline; the liquid inlet pipe of the hydrolyzate head tank 5 communicates with the circulation pipeline.

[0062] The top of the hydrolysis kettle 3 is communicated with an elevated tank 1, and the elevated tank 1 is connected with a hydraulic jet vacuum pump throu...

Embodiment 3

[0077] Example 3, such as figure 1 As shown, a chlorinated glycerol purification device comprises a hydrolysis kettle 3, a hydrolyzate head tank 5, an ion exchange column 6, a distillation kettle 7, and a condenser 8 connected through pipelines successively. On the output pipeline of the condenser 8, A front fraction tank 10 and a finished product tank 9 are connected, and the front fraction tank 10 and the finished product tank 9 are respectively connected with a vacuum unit.

[0078] A circulation pipeline is installed between the lower end and the upper end of the hydrolysis kettle 3, and a circulation pump 4 is installed on the circulation pipeline.

[0079] A glass condenser 2 is connected to the circulation pipeline; the liquid inlet pipe of the hydrolyzate head tank 5 communicates with the circulation pipeline.

[0080] The top of the hydrolysis kettle 3 is communicated with an elevated tank 1, and the elevated tank 1 is connected with a hydraulic jet vacuum pump throu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com